WQS-CB/CS -- NB-IoT/LTE-M Water Quality Sensor Transmitter User Manual

Table of Contents:

- 1. Introduction

- 2. How to use

- 3. Configure WQS-CB

- 3.1 Configure Methods

- 3.2 Serial Access Password

- 3.3 AT Commands Set

- 3.4 Test Uplink and Change Update Interval

- 3.5 Set the receiving time

- 3.6 Reset

- 3.7 +5V

- 3.8 Trigger an uplink by external interrupt

- 3.9 Set the QoS level

- 3.10 Clock logging

- 3.11 Set the TLS mode

- 3.12 Set GNSS open time

- 3.13 Turn on/off GPS

- 3.14 Set GPS positioning interval

- 3.15 Set the search network time

- 3.16 Set the IPv4 or IPv6

- 3.17 Configure Network Category to be Searched for under LTE RAT.

- 3.18 Factory data reset

- 3.19 Set CoAP option

- 3.20 Power on / power off BG95 module

- 3.21 Example Query saved historical records

- 3.22 Uplink log query

- 3.23 Set the downlink debugging mode

- 3.24 PH calibration

- 3.25 ORP calibration

- 3.26 EC calibration

- 3.27 NTU calibration

- 3.28 Set the downlink debugging mode(Since firmware v1.1.0)

- 3.29 Domain name resolution settings(Since firmware v1.1.1)

- 4. Water Qualit Sensors

- 4.6 Residual Chlorine Sensor

- 5. Battery & Power Consumption

- 6. FAQ

- 7. Firmware update

- 8. Packing Info

- 9. Sensors

- 10. Support

1. Introduction

1.1 Overview

WQS-CB/CS is a Main Unit is advanced instruments designed for comprehensive water quality monitoring across various applications. They are ideal for monitoring tap water, industrial water, environmental water, and wastewater,etc,which ofer precise and reliable measurements to ensure water quality standards are met.

WQS-CB/CS is a Main Unit supports 1-3 probes. supports connecting 1 to 3 water quality probes, including EC, pH, DO, ORP, and TS probes.

The Dragino WQS-CB/CS is a NB-IoT/LTE-M Analog Sensor for Internet of Things solution.

WQS-CB/CS will convert the Analog Value to NB-IoT wireless data and then upload to IoT server via NB-IoT or CAT-M1 network.

WQS-CB/CS supports different uplink methods including MQTT, MQTTs, UDP, TCP or CoAP for different application requirement, and support uplinks to various IoT Servers.

WQS-CB/CS supports BLE configure and wireless OTA update which makes user easy to use.

WQS-CB/CS is powered by 8500mAh Li-SOCI2 battery or solar powered+Li-ion battery , it is designed for long-term use up to several years.

Note1: The method of use is that the probe is in direct contact with the water quality. Before using the sensor probe, its protective cover and blue foam cushioning pad must be completely removed. These protective components are designed for transportation and storage, and can effectively resist factors such as physical collision that damage the probe.

Note2: Because the probe needs to adapt to the new water quality environment, the data collected at the beginning will be inaccurate. After standing in the new water quality for two hour, the data collected by the equipment will be more accurate.

1.2 Specifications

Common DC Characteristics:

- Supply Voltage: 2.5v ~ 3.6v

- Operating Temperature: -40 ~ 85°C

I/O Interface:

- Battery controllable output (2.6v ~ 3.6v depends on battery)

- +5v controllable output

- 1 x RS485 Interface

- 1 x UART Interface , 3.3v or 5v

- 1 x Interrupt or Digital IN/OUT pins

- 1 x I2C Interface

- 1 x one wire interface

NB-IoT Spec:

NB-IoT Module: BG95-NGFF

Support Bands:

- B1 @H-FDD: 2100MHz

- B2 @H-FDD: 1900MHz

- B3 @H-FDD: 1800MHz

- B4 @H-FDD: 2100MHz

- B5 @H-FDD: 860MHz

- B8 @H-FDD: 900MHz

- B12 @H-FDD: 720MHz

- B13 @H-FDD: 740MHz

- B17 @H-FDD: 730MHz

- B18 @H-FDD: 870MHz

- B19 @H-FDD: 870MHz

- B20 @H-FDD: 790MHz

- B25 @H-FDD: 1900MHz

- B28 @H-FDD: 750MHz

- B66 @H-FDD: 2000MHz

- B70 @H-FDD: 2000MHz

- B85 @H-FDD: 700MHz

Battery:

- Li/SOCI2 un-chargeable battery

- Capacity: 8500mAh

- Self Discharge: <1% / Year @ 25°C

- Max continuously current: 130mA

- Max boost current: 2A, 1 second

Power Consumption:

- STOP Mode: 10uA @ 3.3v

- Max transmit power: 350mA@3.3v

1.3 Features

- For -NB Bands: B1/B2/B3/B4/B5/B8/B12/B13/B17/B18/B19/B20/B25/B28/B66/B70/B85

- For -CB Bands: B1/B2/B3/B4/B5/B8/B12/B13//B18/B19/B20/B25/B28/B66/B71/B85

- CAT-M1 / LTE-M Bands: B1/B2/B3/B4/B5/B8/B12/B13/B18/B19/B20/B25/B26/B27/B28/B66/B85

- Ultra-low power consumption

- Measure water quality and provide information for water quality conditions

- Support EC / PH / DO / ORP/ TS Type Water Quality Probe

- Support 1 ~ 3 probes

- Multiply Sampling and one uplink

- Uplink via MQTT, MQTTs, TCP, UDP or CoAP

- GNSS for Location Report

- Support Bluetooth v5.1 remote configure and update firmware

- Uplink on periodically

- Downlink to change configure

- Nano SIM card slot for NB-IoT SIM

- 8500mAh Li/SOCl2 Battery (WQS-CB)

- Solar panel + 3000mAh Li-ion battery (WQS-CS)

1.4 Applications

- Smart Buildings & Home Automation

- Logistics and Supply Chain Management

- Smart Metering

- Smart Agriculture

- Smart Cities

- Smart Factory

1.5 Sleep mode and working mode

Deep Sleep Mode: Sensor doesn't have any NB-IoT/CAT-M1 activate. This mode is used for storage and shipping to save battery life.

Working Mode: In this mode, Sensor will work as NB-IoT Sensor to Join NB-IoT network and send out sensor data to server. Between each sampling/tx/rx periodically, sensor will be in IDLE mode), in IDLE mode, sensor has the same power consumption as Deep Sleep mode.

1.6 Button & LEDs

| Behavior on ACT | Function | Action |

|---|---|---|

1~3s 1~3s | Send an uplink | If sensor has already attached to NB-IoT/CAT-M1 network, sensor will send an uplink packet, blue led will blink once. |

>3s >3s | Active Device | Green led will fast blink 5 times, device will enter OTA mode for 3 seconds. And then start to attach NB-IoT/CAT-M1 network. |

x5 x5 | Deactivate Device | Red led will solid on for 5 seconds. Means device is in Deep Sleep Mode. |

Note: When the device is executing a program, the buttons may become invalid. It is best to press the buttons after the device has completed the program execution.

1.7 BLE connection

WQS-CB/CS support BLE remote configure and firmware update.

BLE can be used to configure the parameter of sensor or see the console output from sensor. BLE will be only activate on below case:

- Press button to send an uplink

- Press button to active device.

- Device Power on or reset.

If there is no activity connection on BLE in 60 seconds, sensor will shut down BLE module to enter low power mode.

1.8 Pin Definitions , Switch & SIM Direction

1.8.1 Jumper JP2

Power on Device when put this jumper.

1.8.2 BOOT MODE / SW1

1) ISP: upgrade mode, device won't have any signal in this mode. but ready for upgrade firmware. LED won't work. Firmware won't run.

2) Flash: work mode, device starts to work and send out console output for further debug

1.8.3 Reset Button

Press to reboot the device.

1.8.4 SIM Card Direction

See this link. How to insert SIM Card.

1.8.5 SW2 Jumper (Define UART level to external Sensor)

SW2 defines the voltage level of BOARD_RX and BOARD_TX pins. It should match the external sensor voltage level

1.9 Wiring of DS18B20 temperature sensor

The WQS-CB/CS supports connection to the external temperature sensor DS18B20. The wiring method is as follows:

1.10 Mechanical

1.10.1 for CB version

1.10.2 for CS version

2. How to use

2.1 Example to use for IoT network

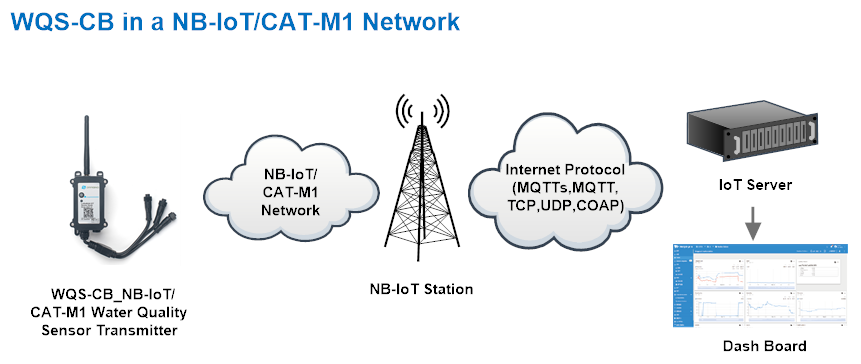

The WQS-CB/CS is equipped with a NB-IoT module, the pre-loaded firmware in WQS-CB/CS will get environment data from sensors and send the value to local NB-IoT network via the NB-IoT module. The NB-IoT network will forward this value to IoT server via the protocol defined by WQS-CB/CS.

Below shows the network structure:

There are two version: -GE and -1T version of WQS-CB.

GE Version: This version doesn't include SIM card or point to any IoT server. User needs to use AT Commands to configure below two steps to set WQS-CB send data to IoT server.

- Install NB-IoT SIM card and configure APN. See instruction of Attach Network.

- Set up sensor to point to IoT Server. See instruction of Configure to Connect Different Servers.

Below shows result of different server as a glance.

| Servers | Dash Board | Comments |

| Node-Red |

| |

| DataCake |

| |

| Tago.IO | ||

| General UDP | Raw Payload. Need Developer to design Dash Board | |

| General MQTT | Raw Payload. Need Developer to design Dash Board | |

| ThingSpeak |

| |

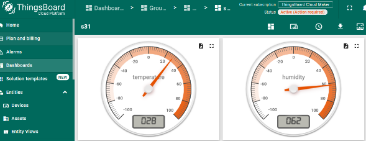

| ThingsBoard |

|

1T Version: This version has 1NCE SIM card pre-installed and configure to send value to ThingsEye. User Just need to select the sensor type in ThingsEyeand Activate WQS-CB/CS and user will be able to see data in ThingsEye. See here for ThingsEye Config Instruction.

2.2 Uplink Payload

To meet different server requirement, WQS-CB supports different payload type.

Includes:

- General JSON format payload. (Type=5)

- HEX format Payload. (Type=0)

- ThingSpeak Format. (Type=1)

- ThingsBoard Format. (Type=3)

User can specify the payload type when choose the connection protocol. Example:

AT+PRO=1,0 // Use COAP Connection & hex Payload

AT+PRO=1,5 // Use COAP Connection & Json Payload

AT+PRO=2,0 // Use UDP Connection & hex Payload

AT+PRO=2,5 // Use UDP Connection & Json Payload

AT+PRO=3,0 // Use MQTT Connection & hex Payload

AT+PRO=3,1 // Use MQTT Connection & ThingSpeak

AT+PRO=3,3 // Use MQTT Connection & ThingsBoard

AT+PRO=3,5 // Use MQTT Connection & Json Payload

AT+PRO=4,0 // Use TCP Connection & hex Payload

AT+PRO=4,5 // Use TCP Connection & Json Payload

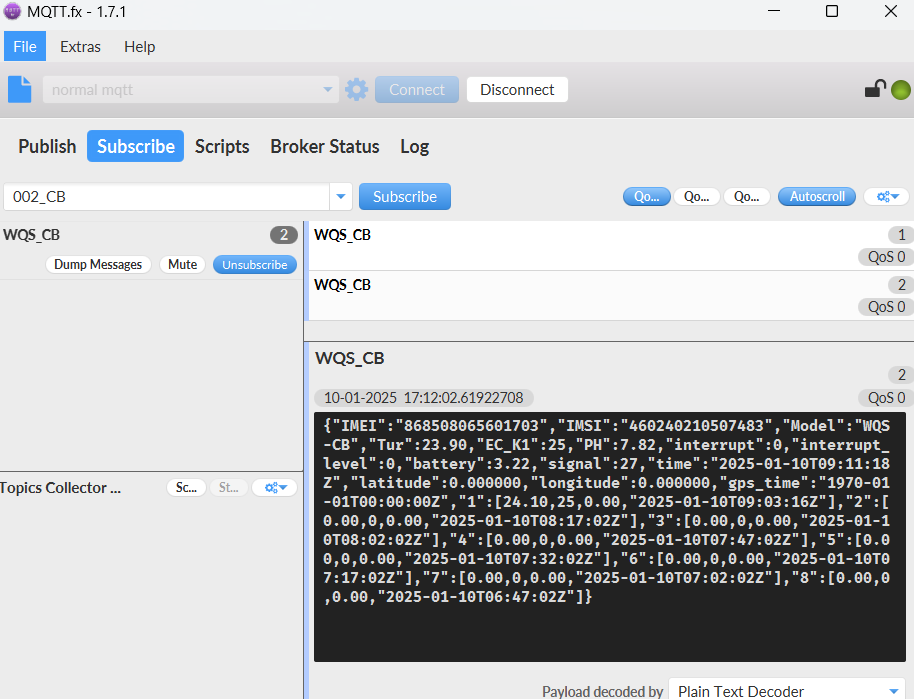

2.2.1 General Json Format(Type=5)

This is the General Json Format. As below:

{"IMEI":"868508065601703","IMSI":"460240210507483","Model":"WQS-CB","Tur":23.90,"EC_K1":25,"PH":7.82,"interrupt":0,"interrupt_level":0,"battery":3.22,"signal":27,"time":"2025-01-10T09:11:18Z","latitude":0.000000,"longitude":0.000000,"gps_time":"1970-01-01T00:00:00Z","1":[24.10,25,0.00,"2025-01-10T09:03:16Z"],"2":[0.00,0,0.00,"2025-01-10T08:17:02Z"],"3":[0.00,0,0.00,"2025-01-10T08:02:02Z"],"4":[0.00,0,0.00,"2025-01-10T07:47:02Z"],"5":[0.00,0,0.00,"2025-01-10T07:32:02Z"],"6":[0.00,0,0.00,"2025-01-10T07:17:02Z"],"7":[0.00,0,0.00,"2025-01-10T07:02:02Z"],"8":[0.00,0,0.00,"2025-01-10T06:47:02Z"]}

Notice, from above payload:

- Tur, EC_K1, PH, interrupt, interrupt_level, battery, signal, time, latitude, longitude, gps_time are the value at uplink time.

- Json entry 1 ~ 8 are the last 1 ~ 8 sampling data as specify by AT+CLOCKLOG=1,65535,15,8 Command. Each entry includes (from left to right): Tur, EC_K1, PH & Sampling time.

- Since I tested with Turbidity Sensor (DR-TS1), EC K1 Sensor, and PH Sensor, the WQS-CB recognizes and sends readings for these sensors.

WQS-CB/CS supports six types of water quality sensors, the six sensor data sequence is: TS1, DO1, ORP, ECK10, ECK1, PH01

No matter which two or three sensors you're connected to, they're all in the same data order as above.

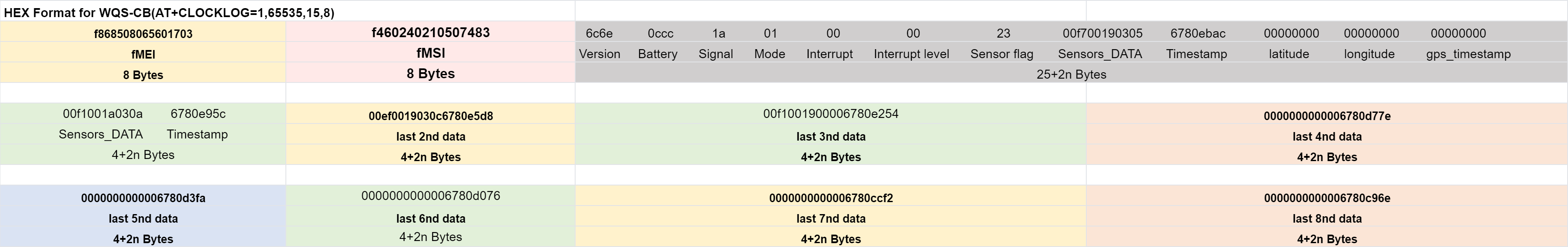

2.2.2 HEX format Payload(Type=0)

This is the HEX Format. As below:

f868508065601703f4602402105074836c6e0ccc1a0100002300f7001903056780ebac00000000000000000000000000f1001a030a6780e95c00ef0019030c6780e5d800f1001900006780e2540000000000006780d77e0000000000006780d3fa0000000000006780d0760000000000006780ccf20000000000006780c96e

z

z

Device ID(f+IMEI): f868508065601703= 868508065601703

SIM Card ID(f+IMSI): f460240210507483= 460240210507483

Version:

These bytes include the hardware and software version.

Higher byte: Specify Sensor Model: 0x6C for WQS-CB/CS

Lower byte: Specify the software version: 0x6e=110, means firmware version 1.1.0

BAT (Battery Info):

Ex1: 0x0ccc = 3276mV

Signal:

NB-IoT Network signal Strength.

Ex1: 0x1a = 26

0 -113dBm or less

1 -111dBm

2...30 -109dBm... -53dBm

31 -51dBm or greater

99 Not known or not detectable

Interrupt:

This data field shows if this packet is generated by interrupt or not.

Example:

If byte[0]&0x01=0x00 : Normal uplink packet.

If byte[0]&0x01=0x01 : Interrupt Uplink Packet.

Interrupt_level:

This byte shows whether the interrupt is triggered by a high or low level.

Ex1: 0x00 Interrupt triggered by falling edge (low level)

Ex2: 0x01 Interrupt triggered by rising edge (high level)

Sensor flag:

There are six types of water quality sensors, each of which is assigned a position in the memory.

One byte, using its binary Bit5~bit0: 00000000

in order: TS1, DO1, ORP, ECK10, ECK1, PH01

Example:

0x23(H)=00100011(B)

Then the sensors used and their data sequence are: TS1(Turbidity Sensor), ECK1(EC K1 Sensor), PH01(PH Sensor).

Sensor DATA:

The sequence of sensor data is consistent with the sequence of sensors identified.

As mentioned above, the sensors I connected are TS1, ECK1 and PH01, the Sensor_flag is 100011.

Note: The data for each sensor is 2 bytes.

Example:

0x00f7 0019 0305

TS1: 0x00f7= 247/10 =24.70NTU

ECK1: 0x0019= 25us/cm

PH01: 0x0305= 773/100 =7.73PH

TimeStamp & GPS Timestamp

Unit TimeStamp Example: 6780ebac(H) = 1736502188(D)

Put the decimal value into this link(https://www.epochconverter.com/) to get the time.

Latitude:

EX1: 0x00000000 // Locating fails or is not enabled.

EX2: 0x015a77dc(H)=22706410(D): 22.706410

Longitutde:

EX1: 0x00000000 // Locating fails or is not enabled.

EX2: 0x06cf3c7a(H)=114244730(D): 114.244730

GPS_Timestamp:

EX1: 0x00000000 // The value is "1970-01-01T00:00:00Z" in JSON format. The initial GPS time is not refreshed if GPS positioning is disabled or fails.

EX2: 0x6682595d =1719818589 = 2024-07-01 15:23:09

2.2.3 ThingsBoard Payload(Type=3)

Type3 payload special design for ThingsBoard, it will also configure other default server to ThingsBoard.

{

"topic": "WQS_CB",

"payload": {

"IMEI": "868508065601703",

"IMSI": "460240210507483",

"Model": "WQS-CB",

"Tur": 32.3,

"DO": 12.68,

"interrupt": 0,

"interrupt_level": 0,

"battery": 3.24,

"signal": 23,

"time": "2025-01-11T03:30:01Z",

"latitude": 0.0,

"longitude": 0.0,

"gps_time": "1970-01-01T00:00:00Z",

"1": [0.0, 0.0, "2025-01-11T03:13:34Z"],

"2": [0.0, 0.0, "2025-01-11T02:58:34Z"],

"3": [0.0, 0.0, "2025-01-11T02:43:34Z"],

"4": [0.0, 0.0, "2025-01-11T02:28:34Z"],

"5": [0.0, 0.0, "2025-01-11T02:13:34Z"],

"6": [0.0, 0.0, "2025-01-11T01:58:34Z"],

"7": [0.0, 0.0, "2025-01-11T01:43:34Z"],

"8": [0.0, 0.0, "2025-01-11T01:28:34Z"]

}

}

2.2.4 ThingSpeak Payload(Type=1)

This payload meets ThingSpeak platform requirement. I used Turbidity sensor:DR-TS1 and Dissolved Oxygen Sensor:DR-D01, so the data is as follows:

field1=Tur value&field2=DO value&field3=Interrupt&field4=Interrupt_level&field5=Latitude&field6=Longitude&field7=BatV&field8=Singal

3. Configure WQS-CB

3.1 Configure Methods

WQS-CB/CS supports below configure method:

- AT Command via Bluetooth Connection (Recommended): BLE Configure Instruction.

- AT Command via UART Connection : See UART Connection.

3.2 Serial Access Password

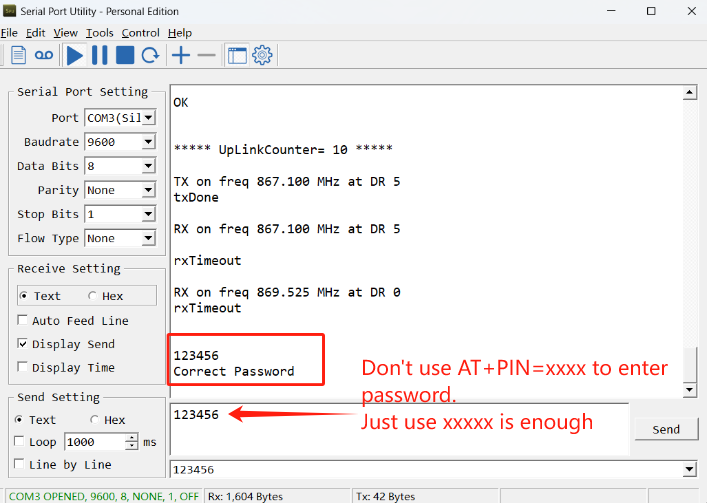

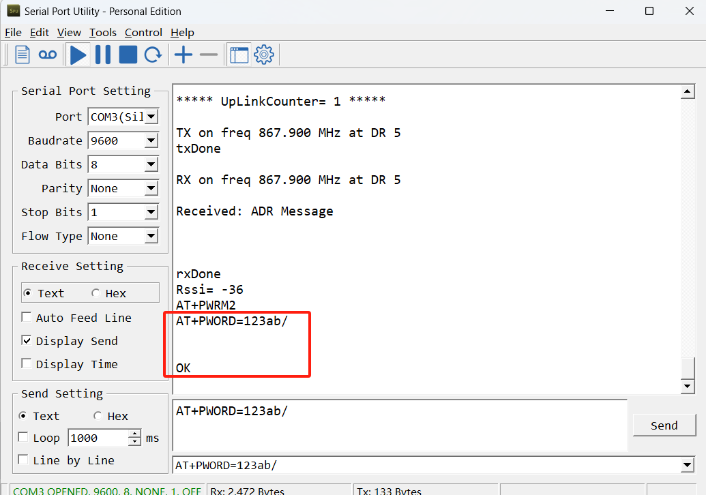

After the Bluetooth or UART connection is successful, use the Serial Access Password to enter the AT command window.

The label on the box of the node will print the initial password: AT+PIN=xxxxxx, and directly use the six-digit password to access the AT instruction window.

If you need to change the password, use AT+PWORD=xxxxxx (6 characters), NB nodes only support lowercase letters.

Note: After entering the command, you need to add a line break, and you can also set automatic line breaks in the Bluetooth tool or UART connection tool.

3.3 AT Commands Set

AT+<CMD>? : Help on <CMD>

AT+<CMD> : Run <CMD>

AT+<CMD>=<value> : Set the value

AT+<CMD>=? : Get the value

General Commands

AT : Attention

AT? : Short Help

AT+MODEL : Get module information

ATZ : Trig a reset of the MCU

AT+CFGMOD : Working mode selection

AT+DEUI : Get or set the Device ID

AT+CFG : Print all settings

AT+SERVADDR: Get or Set the Server address

AT+TDC : Get or set the application data transmission interval in s

AT+INTMOD : Get or Set the trigger interrupt mode (0:input,1:falling or rising,2:falling,3:rising)

AT+APN : Get or set the APN

AT+5VT : Get or Set extend the time of 5V power

AT+PRO : Get or Set usage agreement (1:COAP,2:UDP,3:MQTT,4:TCP)

AT+RXDL : Get or Set the receiving time

AT+CALPH : PH calibration Standard buffering (4:4.01,6:6.86,9:9.18)

AT+CALORP : ORP calibration Standard buffering(86:86mv,256:256mv)

AT+CALEC : EC calibration Standard buffering (1:1413HS/cm,10:12.88mS/cm)

AT+CALNTU : NTU calibration Standard buffering (0:0NTU,2:200NTU,4:400NTU,6:600NTU,8:800NTU,10:1000NTU)

AT+GETSENSORVALUE : Returns the current sensor measurement

AT+DNSCFG : Get or Set DNS Server

AT+CSQTIME : Get or Set the time to join the network

AT+GDNS : Get or Set the DNS

AT+TLSMOD : Get or Set the TLS mode

AT+SLEEP : Get or Set the sleep mode

AT+IPTYPE : Set the IPv4 or IPv6

AT+QSW : Power on and power off BG95 module

AT+CLOCKLOG: Get or set SHT record time

AT+QBAND: Get or set Frequency Band

AT+IOTMOD: Configure Network Category to be Searched for under LTE RAT

AT+DOWNTE: Get or set the conversion between the standard version and 1T version downlinks

MQTT Management

AT+CLIENT : Get or Set the MQTT clientID

AT+UNAME : Get or Set the MQTT Username

AT+PWD : Get or Set the MQTT password

AT+PUBTOPIC: Get or set MQTT publishing topic

AT+SUBTOPIC: Get or set MQTT subscription topic

AT+MQOS : Set the QoS level of MQTT

COAP Management

AT+URI1: Get or set CoAP option 1

AT+URI2: Get or set CoAP option 2

AT+URI3: Get or set CoAP option 3

AT+URI4: Get or set CoAP option 4

AT+URI5: Get or set CoAP option 5

AT+URI6: Get or set CoAP option 6

AT+URI7: Get or set CoAP option 7

AT+URI8: Get or set CoAP option 8

GPS

AT+GNSST : Extend the time to turn on GNSS

AT+GPS : Turn off and on GPS

AT+GTDC : Get or set GPS positioning interval in units of h

Information

AT+FDR1 : Reset parameters to factory default values except for passwords

AT+FDR : Reset Parameters to Factory Default

AT+PWORD : Get or set the System password

AT+CDP : Read or Clear cached data

AT+LDATA : Get the last upload data

AT+GETLOG : Print serial port logs

3.4 Test Uplink and Change Update Interval

By default, Sensor will send uplinks every 2 hours.

User can use below commands to change the uplink interval.

AT Command: AT+TDC

Example: AT+TDC=7200 // Set Update Interval to 7200 seconds

Downlink Commands: 0x01

Format: Command Code (0x01) followed by 3 bytes.

Example: 12 hours= 43200 seconds 43200(D)=0xA8C0(H)

Downlink Payload: 01 00 A8 C0 // AT+TDC=43200, Set Update Interval to 12 hours.

Note: User can also push the button for more than 1 second to activate an uplink.

3.5 Set the receiving time

Feature: Extend the receiving time

AT Command: AT+RXDL

Example: AT+RXDL=1000 // Set the receiving time delay to 1000ms

Downlink Commands: 0x03

Format: Command Code (0x03) followed by 3 bytes.

Example: Downlink Payload: 03 00 03 E8 // AT+RXDL=1000

3.6 Reset

Feature: Trig a reset of the MCU.

AT Command: ATZ

Downlink Commands: 0x04FF

3.7 +5V

Feature: Set extend the time of 5V power.

AT Command: AT+5VT

Example: AT+5VT=2000 // Set extend the time of 5V power to 2000 ms

Downlink Commands: 0x05

Format: Command Code (0x05) followed by 3 bytes.

Example: Downlink Payload: 05 00 07 D0 // AT+5VT=2000

3.8 Trigger an uplink by external interrupt

WQS-CB/CS has an external trigger interrupt function. Users can use the GPIO_EXTI pin to trigger the upload of data packets.

AT command:

- AT+INTMOD // Set the trigger interrupt mode

- AT+INTMOD=0 // Input, disable Interrupt

- AT+INTMOD=1 // Trigger by rising and falling edge

- AT+INTMOD=2 // Trigger by falling edge

- AT+INTMOD=3 // Trigger by rising edge

Downlink Commands: 0x06

Format: Command Code (0x06) followed by 3 bytes.

Example1: Downlink Payload: 06 00 00 01 // AT+INTMOD=1

Example2: Downlink Payload: 06 00 00 03 // AT+INTMOD=3

3.9 Set the QoS level

This command is used to set the QoS level of MQTT.

AT command:

- AT+MQOS=xx // 0~2

Downlink command: 0x07

Format: Command Code (0x07) followed by 1 byte.

Ex1: Downlink payload: 0x0700 // AT+MQOS=0

Ex2: Downlink payload: 0x0701 // AT+MQOS=1

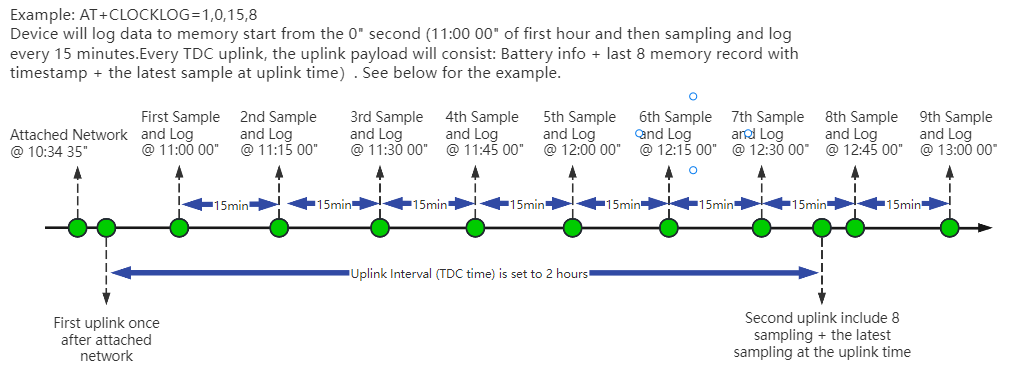

3.10 Clock logging

Sometimes when we deploy lots of end nodes in field. We want all sensors sample data at the same time, and upload these data together for analyze. In such case, we can use clock loging feature.

We can use this command to set the start time of data recording and the time interval to meet the requirements of the specific collection time of data.

AT command: AT+CLOCKLOG=a,b,c,d

a: 0: Disable Clock logging. 1: Enable Clock Logging

b: Specify First sampling start second: range (0 ~ 3599, 65535) // Note: If parameter b is set to 65535, the log period starts after the node accesses the network and sends packets.

c: Specify the sampling interval: range (0 ~ 255 minutes)

d: How many entries should be uplink on every TDC (max 32)

Note: To disable clock recording, set the following parameters: AT+CLOCKLOG=1,65535,0,0

Example:

AT+CLOCKLOG=1,65535,1,5

After the node sends the first packet, data is recorded to the memory at intervals of 1 minute. For each TDC uplink, the uplink load will include: battery information + the last 5 memory records (payload + timestamp).

Note: Users need to synchronize the server time before configuring this command. If the server time is not synchronized before this command is configured, the command takes effect only after the node is reset.

Downlink command: 0x08

Format: Command Code (0x08) followed by 5 bytes.

- Example 1: Downlink Payload: 08 01 FFFF 0F 08 // Set SHT record time: AT+CLOCKLOG=1,65535,15,8

- Example 2: Downlink Payload: 08 01 04B0 0F 08 // Set SHT record time: AT+CLOCKLOG=1,1200,15,8

Note: When entering the downlink payload, there must be no Spaces between bytes.

3.11 Set the TLS mode

Refer to this link (MQTT Connection to send data to Tago.io)to use the TLS mode.

AT Command: AT+TLSMOD

Example 1: AT+TLSMOD=0,0 // Disable TLS Mode.

Example 2: AT+TLSMOD=1,0 // No authentication

AT+TLSMOD=1,1 // Perform server authentication

AT+TLSMOD=1,2 // Perform server and client authentication if requested by the remote server

Downlink command: 0x09

Format: Command Code (0x09) followed by 2 bytes.

Example1: Downlink Payload: 09 00 00 // AT+TLSMOD=0,0

Example2: Downlink Payload: 09 01 02 // AT+TLSMOD=1,2

3.12 Set GNSS open time

Extend the time to turn on GNSS. The automatic GPS location time is extended when the node is activated.

AT Command: AT+GNSST

Example: AT+GNSST=30 // Set the GPS positioning time to 30 seconds

Downlink command: 0x10

Format: Command Code (0x10) followed by 2 bytes.

Example: Downlink Payload: 10 00 1E // AT+GNSST=30

3.13 Turn on/off GPS

AT Command: AT+GPS

Ex1: AT+GPS=0 // Turn off GPS

Ex2: AT+GPS=1 // Turn on GPS

Downlink command: 0x11

Format: Command Code (0x11) followed by 1 byte.

Example: Downlink Payload: 11 01 // AT+GPS=1

3.14 Set GPS positioning interval

Feature: Set GPS positioning interval (unit: hour).

When GPS is enabled, the node automatically locates and uplinks each time it passes GTDC time after activation.

AT Command: AT+GTDC

Example: AT+GTDC=24 // Set the GPS positioning interval to 24h.

Downlink command: 0x12

Format: Command Code (0x12) followed by 3 bytes.

Example: 24 hours: 24(D)=0x18(H)

Downlink Payload: 12 00 00 18 // AT+GTDC=24

3.15 Set the search network time

Feature: Get or Set the time to join the network(unit: minutes).

AT Command: AT+CSQTIME

Example: AT+CSQTIME=10 // Set the search time to 10 minutes.

Downlink command: 0x13

Format: Command Code (0x13) followed by 1 byte.

Example: Downlink Payload: 13 0A // AT+CSQTIME=10

3.16 Set the IPv4 or IPv6

This command is used to set IP version.

AT command:

- AT+IPTYPE=1 // IPv4

- AT+IPTYPE=2 // IPv6

3.17 Configure Network Category to be Searched for under LTE RAT.

AT command: AT+IOTMOD=xx

xx: 0: eMTC

1: NB-IoT

2: eMTC and NB-IoT

3.18 Factory data reset

Two different restore factory Settings configurations.

AT command:

- AT+FDR // Reset Parameters to Factory Default.

- AT+FDR1 // Reset parameters to factory default values except for passwords.

3.19 Set CoAP option

Feature: Set CoAP option, follow this link to set up the CoaP protocol.

AT command: AT+URI1~AT+URI8

AT+URI1=11,"i" // "i/" indicates that the endpoint supports observation mode. In -CB products, fixed setting AT+URI1=11,"i"

AT+URI2=11,"CoAP endpoint URl" // 11 is a fixed parameter.

Example: i/13a35fbe-9515-6e55-36e8-081fb6aacf86

AT+URI1=11,"i"

AT+URI2=11,"13a35fbe-9515-6e55-36e8-081fb6aacf86"

--> If multiple groups of CoAP endpoint urls:

AT+URI3=11,"i"

AT+URI4=11,"CoAP endpoint URl"

3.20 Power on / power off BG95 module

This command is used to power on and power off BG95 module.

- AT command: AT+QSW

The module is powered on after the command is sent for the first time, and powered off after the command is sent again.

3.21 Example Query saved historical records

Read or Clear cached data.

- AT command: AT+CDP

This command can be used to search the saved history, recording up to 32 groups of data, each group of historical data contains a maximum of 100 bytes.

- AT command: AT+CDP=0

Clear cached data.

3.22 Uplink log query

- AT command: AT+GETLOG

This command can be used to query upstream logs of data packets.

3.23 Set the downlink debugging mode

Feature: Set the conversion between the standard version and 1T version downlinks.

AT command: AT+DOWNTE

| Command Example | Function/Parameters | Response/Explanation |

|---|---|---|

| AT+DOWNTE=? | Get current Settings | 0,0 (default) |

AT+DOWNTE=a,b | a: Set the conversion between the downlink of the standard version and 1T version | 0: Set the downlink of the standard version. |

| b: Enable/Disable downlink debugging | 0: Disable downlink debugging mode. |

Example:

- AT+DOWNTE=0,1 // Set to standard version downlink, and enable downlink debugging.

- AT+DOWNTE=1,1 // Set to 1T version downlink, and enable downlink debugging.

Downlink Command:

No downlink commands for feature

3.24 PH calibration

Specific operation steps(Applicable to all sensors)

1. Put the sensor into the corresponding calibration liquid.

2. Restart the device.

3. Send calibration instructions.

4. Receive the byte corresponding to return.

5. Received OK is a successful calibration.

Feature: This command is used for three-point calibration of PH standard buffer solutions.

AT command: AT+CALPH

| Command Example | Function | Response |

|---|---|---|

| AT+CALPH=4 | Calibrate 4.00 standard buffer | HEX:10 06 00 22 07 24 28 aa |

AT+CALPH=6 | Calibrate 6.86 standard buffer | HEX:10 06 00 21 07 4e 58 85 |

| AT+CALPH=9 | Calibrate 9.18 standard buffer | HEX:10 06 00 20 08 bc 8d 30 |

Downlink Command:

No downlink commands for feature

3.25 ORP calibration

Feature: This command is used for two-point calibration of ORP standard buffer solutions.

AT command: AT+CALORP

| Command Example | Function | Response |

|---|---|---|

AT+CALORP=86 | Calibrate 86mV standard buffer | HEX:13 06 00 24 07 dc c9 1a |

| AT+CALORP=256 | Calibrate 256mV standard buffer | HEX:13 06 00 25 07 37 d8 95 |

Downlink Command:

No downlink commands for feature

3.26 EC calibration

Feature: This command is used for two-point calibration of EC standard buffer solutions.

AT command: AT+CALEC

| Command Example | Function | Response |

|---|---|---|

AT+CALEC=1 | Calibrate 1413HS/cm standard buffer | HEX:12 01 00 26 00 02 A2 A0 |

| AT+CALEC=10 | Calibrate 12.88mS/cm standard buffer | HEX:11 06 00 26 00 02 EB 50 |

Downlink Command:

No downlink commands for feature

3.27 NTU calibration

Feature: This command is used for turbidity calibration.

AT command: AT+CALNTU

| Command Example | Function | Response |

|---|---|---|

| AT+CALNTU=0 | Calibrate 0NTU turbidity solution | HEX:15 06 00 5E 00 01 2A CC |

| AT+CALNTU=2 | Calibrate 200NTU turbidity solution | HEX:15 06 00 5E 00 02 6A CD |

| AT+CALNTU=4 | Calibrate 400NTU turbidity solution | HEX:15 06 00 5E 00 03 AB 0D |

| AT+CALNTU=6 | Calibrate 600NTU turbidity solution | HEX:15 06 00 5E 00 04 EA CF |

| AT+CALNTU=8 | Calibrate 800NTU turbidity solution | HEX:15 06 00 5E 00 05 2B 0F |

| AT+CALNTU=10 | Calibrate 1000NTU turbidity solution | HEX:15 06 00 5E 00 06 6B 0E |

Downlink Command:

No downlink commands for feature

3.28 Set the downlink debugging mode(Since firmware v1.1.0)

Feature: Set the conversion between the standard version and 1T version downlinks.

AT command: AT+DOWNTE

| Command Example | Function/Parameters | Response/Explanation |

|---|---|---|

| AT+DOWNTE=? | Get current Settings | 0,0 (default) OK |

AT+DOWNTE=a,b | a: Set the conversion between the downlink of the standard version and 1T version | 0: Set the downlink of the standard version. |

| b: Enable/Disable downlink debugging | 0: Disable downlink debugging mode. |

Example:

- AT+DOWNTE=0,1 // Set to standard version downlink, and enable downlink debugging.

- AT+DOWNTE=1,1 // Set to 1T version downlink, and enable downlink debugging.

Downlink Command:

No downlink commands for feature

3.29 Domain name resolution settings(Since firmware v1.1.1)

Feature: Set static DNS resolution IP address.

AT command: AT+BKDNS

| Command Example | Function/Parameters | Response/Explanation |

|---|---|---|

AT+BKDNS=? | Get current Settings | 1,0,NULL (default) |

AT+BKDNS=a,b,c | a: Enable/Disable static DNS resolution. | 0: Disable static DNS resolution 1: Enable static DNS resolution. The ip address will be saved after the domain name is resolved, if the next domain name resolution fails, the last saved ip address will be used. |

| b: Meaningless. | Set to 0. | |

c: Set the IP address manually. | The format is the same as AT+SERVADDR. |

Example:

- AT+BKDNS=0,0,NULL //Disable static DNS resolution.

- AT+BKDNS=1,0,NULL // Enable static DNS resolution.

- AT+BKDNS=1,0,3.69.98.183,1883 //Enable static DNS resolution, if domain name resolution succeeds, the node uses the ip address successfully resolved and saves it to parameter c. If the domain name resolution fails, use the manually set ip address: 3.69.98.183 for communication.

Downlink Command:

No downlink commands for feature.

4. Water Qualit Sensors

4.1 PH Sensor

PH01 is a device for measuring the pH value (hydrogen ion concentration index, acidity and alkalinity) of a solution.

It adopts an integrated design, is lighter and simpler in structure, and is more convenient to use. The waterproof grade is IP68.

The reference electrode adopts a double salt bridge design, which has stronger anti-pollution ability.

This product is suitable for industrial sewage, domestic sewage, agriculture, aquaculture and other scenes in non-corrosive weak acid and weak alkali environments.

4.1.1 Feature

- pH measurement range 0~14pH, resolution 0.01pH.

- One-piece design, light and simple structure, easy to use.

- The reference adopts a double salt bridge design, which has stronger anti-pollution ability and waterproof grade IP68.

- The equipment adopts a wide voltage power supply DC 7~30V.

4.1.2 Specification

- Power supply: DC7~30V

- Power consumption: ≤0.5W

- Communication interface: RS485; standard MODBUS-RTU protocol; communication baud rate: default 9600

- pH measurement range: 0~14.00pH; resolution: 0.01pH

- pH measurement error: ±0.15pH

- Repeatability error: ±0.02pH

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Waterproof grade: IP68

- Pressure resistance: 0.6MPa

4.1.3 Dimension

4.1.4 Installation Notice

Do not power on while connect the cables. Double check the wiring before power on.

Installation Photo as reference:

Submerged installation:

The lead wire of the equipment passes through the waterproof pipe, and the 3/4 thread on the top of the equipment is connected to the 3/4 thread of the waterproof pipe with raw tape. Ensure that the top of the equipment and the equipment wire are not flooded.

Pipeline installation:

Connect the equipment to the pipeline through the 3/4 thread.

Sampling:

Take representative water samples according to sampling requirements. If it is inconvenient to take samples, you can also put the electrode into the solution to be tested and read the output data. After a period of time, take out the electrode and clean it.

Measure the pH of the water sample:

First rinse the electrode with distilled water, then rinse it with the water sample, then immerse the electrode in the sample, carefully shake the test cup or stir it to accelerate the electrode balance, let it stand, and record the pH value when the reading is stable.

4.1.5 Maintenance

- The equipment itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself. Contact us as soon as possible!

- There is an appropriate amount of soaking solution in the protective bottle at the front end of the electrode. The electrode head is soaked in it to keep the glass bulb and the liquid junction activated. When measuring, loosen the bottle cap, pull out the electrode, and rinse it with pure water before use.

- Preparation of electrode soaking solution: Take a packet of PH4.00 buffer, dissolve it in 250 ml of pure water, and soak it in 3M potassium chloride solution. The preparation is as follows: Take 25 grams of analytical pure potassium chloride and dissolve it in 100 ml of pure water.

- The glass bulb at the front end of the electrode cannot come into contact with hard objects. Any damage and scratches will make the electrode ineffective.

- Before measurement, the bubbles in the electrode glass bulb should be shaken off, otherwise it will affect the measurement. When measuring, the electrode should be stirred in the measured solution and then placed still to accelerate the response.

- The electrode should be cleaned with deionized water before and after measurement to ensure accuracy.

- After long-term use, the pH electrode will become passivated, which is characterized by a decrease in sensitivity gradient, slow response, and inaccurate readings. At this time, the bulb at the bottom of the electrode can be soaked in 0.1M dilute hydrochloric acid for 24 hours (0.1M dilute hydrochloric acid preparation: 9 ml of hydrochloric acid is diluted to 1000 ml with distilled water), and then soaked in 3.3M potassium chloride solution for 24 hours. If the pH electrode is seriously passivated and soaking in 0.1M hydrochloric acid has no effect, the pH electrode bulb can be soaked in 4% HF (hydrofluoric acid) for 3-5 seconds, washed with pure water, and then soaked in 3.3M potassium chloride solution for 24 hours to restore its performance.

- Glass bulb contamination or liquid junction blockage can also cause electrode passivation. At this time, it should be cleaned with an appropriate solution according to the nature of the contaminant.

The equipment should be calibrated before each use. For long-term use, it is recommended to calibrate once every 3 months. The calibration frequency should be adjusted appropriately according to different application conditions (degree of dirt in the application, deposition of chemical substances, etc.). After aging, the electrodes should be replaced in time.

4.1.6 Calibration

This device uses three-point calibration, and three known PH standard solutions need to be prepared.

The steps are as follows:

(1) Wash the electrode in distilled water, and put it in 9.18 standard buffer solution. After the data stabilizes, enter the following calibration command, that is, 9.18 calibration is completed. "AT+CALPH=9"

(2) Wash the electrode in distilled water, and put it in 6.86 standard buffer solution. After the data stabilizes, enter the following calibration command, that is, 6.86 calibration is completed; "AT+CALPH=6"

(3) Wash the electrode in distilled water, and put it in 4.01 standard buffer solution. After the data stabilizes, enter the following calibration command, that is, 4.00 calibration is completed. "AT+CALPH=4"

4.2 EC Sensor

EC K1/K10 is a device for measuring the conductivity of solutions. EC K1/K10 adopts an integrated design, which is lighter and simpler in structure and more convenient to use.

The waterproof grade is IP68. It can be widely used in continuous monitoring of the conductivity of aqueous solutions such as cross-section water quality, aquaculture, sewage treatment, environmental protection, pharmaceuticals, food and tap water.

4.2.1 Feature

- Conductivity measurement range is 0-2000us/cm; 10~20000us/cm.

- Integrated design, light and simple structure, easy to use.

- Waterproof grade IP68.

- With salinity and TDS conversion function.

- RS485 communication interface: MDDBUS RTU communication protocol can be easily connected to the computer for monitoring and communication.

- ModBus communication address can be set and baud rate can be modified.

- The device adopts wide voltage power supply, DC 7~30V is available.

4.2.2 Specification

- Power supply: DC7~30V

- Power consumption: ≤0.5W

- Communication interface: RS485; standard MODBUS-RTU protocol; communication baud rate: default 9600

- Conductivity measurement range: K=1: 0~2000μs/cm; resolution: 1μs/cm K=10: 10~20000μs/cm; resolution: 10μs/cm 200:0-200000 μS/cm; resolution: 1 μS/cm

- Conductivity measurement error: ±1%FS

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Waterproof grade: IP68

- Pressure resistance: 0.6MPa

4.2.3 Dimension

4.2.4 Installation Notice

Selection of matching electrode constant

Electrode installation form

A:Side wall installation

B:Top flange installation

C:Pipeline bend installation

D:Pipeline bend installation

E:Flow-through installation

F:Submerged installation

Several common installation methods of electrodes

When installing the sensor on site, you should strictly follow the correct installation method shown in the following picture. Incorrect installation method will cause data deviation.

A. Several common incorrect installation methods

Error cause: The electrode joint is too long, the extension part is too short, the sensor is easy to form a dead cavity, resulting in measurement error.

Error cause: Measurement error or instability may occur due to water flow not being able to fill the pipe or air accumulation at high altitudes.

B. Correct installation method

4.2.5 Maintenance

- The equipment itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself, and contact us as soon as possible.

- If the electrode is not used for a long time, it can generally be stored in a dry place, but it must be placed (stored) in distilled water for several hours before use to activate the electrode. Electrodes that are frequently used can be placed (stored) in distilled water.

- Cleaning of conductivity electrodes: Organic stains on the electrode can be cleaned with warm water containing detergent, or with alcohol. Calcium and magnesium precipitates are best cleaned with 10% citric acid. The electrode plate or pole can only be cleaned by chemical methods or by shaking in water. Wiping the electrode plate will damage the coating (platinum black) on the electrode surface.

- The equipment should be calibrated before each use. It is recommended to calibrate it every 3 months for long-term use. The calibration frequency should be adjusted appropriately according to different application conditions (degree of dirt in the application, deposition of chemical substances, etc.).

4.2.6 Calibration

This device uses one-point calibration, and you need to prepare a known E standard solution. When the mileage K=1, 1~2000 uses 1413uS/cm standard solution, and when the mileage K=10, 10~20000 uses 12.88mS/cm standard solution.

The steps are as follows:

(1) Put the electrode in distilled water to clean it. When the mileage is 1~2000, use 1413HS/cm standard solution.After the data is stable, enter the following calibration command

"AT+CALEC=1"

(2) Put the electrode in distilled water to clean it. When the range is 10~20000, use 12.88mS/cm standard solution.After the data is stable, enter the following calibration command

"AT+CALEC=10"

4.3 ORP Sensor

ORP01 is a device for measuring the redox potential of a solution. It uses high-purity platinum to make an ORP composite electrode, which has strong acid and alkali resistance and antioxidant capacity, and has high measurement accuracy, fast response, and good stability.

The electrode can automatically compensate according to temperature. It is suitable for online monitoring of the redox potential of cyanide-containing and chromium-containing wastewater.

4.3.1 Feature

- ORP measurement range -1999~1999mV, resolution 1mV.

- Applicable electrode temperature 0~80℃.

- The electrode is made of high-purity platinum, which has strong acid and alkali resistance and antioxidant capacity, high measurement accuracy, fast response and good stability.

- RS485 communication interface: ModBus-RTU communication protocol can be easily connected to the computer for monitoring and communication.

- ModBus communication address can be set and baud rate can be modified.

- The equipment adopts wide voltage power supply, DC 7~30V

4.3.2 Specification

- Measuring range: -1999~1999mV

- Resolution: 1mV

- Output signal: RS485

- Measurement error: ±3mV

- Stability: ≤2mv/24 hours

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Waterproof grade: IP68

- Pressure resistance: 0.6MP

4.3.3 Dimension

4.3.4 Installation Notice

Do not power on while connect the cables. Double check the wiring before power on.

Installation Photo as reference:

Submerged installation:

The lead wire of the equipment passes through the waterproof pipe, and the 3/4 thread on the top of the equipment is connected to the 3/4 thread of the waterproof pipe with raw tape. Ensure that the top of the equipment and the equipment wire are not flooded.

Pipeline installation:

Connect the equipment to the pipeline through the 3/4 thread.

4.3.5 Maintenance

(1) The equipment itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself, and contact us as soon as possible.

(2) In general, ORP electrodes do not need to be calibrated and can be used directly. When there is doubt about the quality and test results of the ORP electrode, the electrode potential can be checked with an ORP standard solution to determine whether the ORP electrode meets the measurement requirements, and the electrode can be recalibrated or replaced with a new ORP electrode. The frequency of calibration or inspection of the measuring electrode depends on different application conditions (the degree of dirt in the application, the deposition of chemical substances, etc.).

(3) There is an appropriate soaking solution in the protective bottle at the front end of the electrode, and the electrode head is soaked in it to ensure the activation of the platinum sheet and the liquid junction. When measuring, loosen the bottle cap, pull out the electrode, and rinse it with pure water before use.

(4) Preparation of electrode soaking solution: Take 25 grams of analytical pure potassium chloride and dissolve it in 100 ml of pure water to prepare a 3.3M potassium chloride solution.

(5) Before measuring, the bubbles in the electrode glass bulb should be shaken off, otherwise it will affect the measurement. When measuring, the electrode should be stirred in the measured solution and then placed still to accelerate the response.

(6) The electrode should be cleaned with deionized water before and after the measurement to ensure the measurement accuracy.

(7) After long-term use, the ORP electrode will be passivated, which is manifested as a decrease in sensitivity gradient, slow response, and inaccurate readings. At this time, the platinum sheet at the bottom of the electrode can be soaked in 0.1M dilute hydrochloric acid for 24 hours (0.1M dilute hydrochloric acid preparation: 9 ml of hydrochloric acid is diluted to 1000 ml with distilled water), and then soaked in 3.3M potassium chloride solution for 24 hours to restore its performance.

(8) Electrode contamination or liquid junction blockage can also cause electrode passivation. At this time, it should be cleaned with an appropriate solution according to the nature of the contaminant. If the platinum of the electrode is severely contaminated and an oxide film is formed, toothpaste can be applied to the platinum surface and then gently scrubbed to restore the platinum's luster.

(9) The equipment should be calibrated before each use. It is recommended to calibrate once every 3 months for long-term use. The calibration frequency should be adjusted appropriately according to different application conditions (degree of dirt in the application, deposition of chemical substances, etc.). After aging, the electrodes should be replaced in time.

4.3.6 Calibration

OPR01 uses two-point calibration. You need to prepare two known ORP standard solutions.

The steps are as follows:

(1) Put the electrode in distilled water to clean it, put it in 86mV standard buffer, wait for the data to stabilize, enter the following calibration command, and the 86mV point calibration is completed.

"AT+CALORP=86"

(2) Put the electrode in distilled water to clean it, put it in 256mV standard buffer, wait for the data to stabilize, enter the following calibration command, and the 256mV point calibration is completed.

"AT+CALORP=256"

4.4 Dissolved Oxygen Sensor

The fluorescence dissolved oxygen sensor is a newly developed online digital sensor, using imported components and advanced production technology and surface mounting technology.

It has an IP68 waterproof rating, and the cable is seawater-proof. It can be directly put into the water without a protective tube, ensuring the long-term stability, reliability and accuracy of the sensor.

The fluorescence dissolved oxygen sensor is based on the principle of quenching active fluorescence by specific substances in physics.

The blue light from a light-emitting diode (LED) shines on the fluorescent material on the inner surface of the fluorescent cap.

The fluorescent material on the inner surface is excited and emits red light.

By detecting the phase difference between the red light and the blue light and comparing it with the internal calibration value, the concentration of oxygen molecules is calculated, and the final value is automatically compensated for temperature and air pressure.

4.4.1 Feature

- Small size, low power consumption, easy to carry.

- Truly achieve low cost, low price, high performance.

- High integration, long life, high reliability.

- Up to four isolations, can resist complex interference conditions on site, waterproof level IP68.

- The electrode uses high-quality low-noise cable, which can make the signal output length reach more than 20 meters.

4.4.2 Specification

- Measuring range: 0-20mg/L, 0-50℃

- Accuracy: 3%, ±0.5℃

- Resolution: 0.01 mg/L, 0.01℃

- Maximum operating pressure: 6 bar

- Output signal: A: 4-20mA (current loop)

- B: RS485 (standard Modbus-RTU protocol, device default address: 01)

- Power supply voltage: 5-24V DC

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Power consumption: ≤0.5W

4.4.3 Dimension

4.4.4 Instructions for use and maintenance

- Sampling: Take representative water samples according to the sampling requirements.

- Determine dissolved oxygen in water samples: First rinse the electrode three times with distilled water, then rinse it three times with the water sample, then immerse the electrode in the sample, carefully shake the test cup or stir it to accelerate the electrode balance, let it stand, and record the dissolved oxygen when the reading is stable.

- If it is inconvenient to take samples, you can also put the electrode in the measured solution, wait for the measured data to stabilize, read the output data, and take out the electrode after a period of time. Clean it.

- After the sample measurement is completed, rinse the electrode three times with distilled water and put the electrode back in the protective solution upright.

Note: When measuring multiple samples, the electrode should be cleaned before measuring the next sample to avoid affecting the experimental data.

If the water conditions are complex and you want accurate data, you need to wipe the sensor probe frequently.

4.4.5 Precautions

- To ensure that the electrode measures correctly on the pipeline, avoid bubbles between the measuring cells that may cause data inaccuracy.

- Please check whether the packaging is intact and whether the product model is consistent with the selected model.

- Do not connect the wires with power on. After the wiring is completed and checked, power can be turned on.

- Do not arbitrarily change the components or wires that have been welded at the factory when using the product.

- The sensor is a precision device. When using it, please do not disassemble it by yourself or contact the sensor surface with sharp objects or corrosive liquids to avoid damaging the product.

4.5 Turbidity Sensor

The turbidity sensor is a newly developed online digital turbidity sensor, using imported components and advanced production technology and surface mounting technology.

It has an IP68 waterproof rating, and the cable is seawater-proof.It can be directly put into the water without a protective tube, ensuring the long-term stability, reliability and accuracy of the sensor. This sensor probe uses a scattered light turbidity measurement method.

Since the turbidity in the water sample causes light to scatter, the intensity of the scattered light in the direction perpendicular to the incident light is measured and compared with the internal calibration value to calculate the turbidity in the water sample.

The ambient light interference is eliminated by infrared light and filters. After linearization processing, the output signal is stable and accurate.

4.5.1 Feature

- RS485 Temperature, Humidity, Illuminance, Pressure sensor

- Axial capacitor filtering is used internally, and 100MΩ resistor increases impedance and enhances stability.

- Small size, low power consumption, and easy to carry.

- Truly achieve low cost, low price, and high performance.

- High integration, long life, and high reliability.

- Up to four isolations can resist complex interference conditions on site, and the waterproof level is IP68.

- The electrode uses high-quality low-noise cable, which can make the signal output length reach more than 20 meters

4.5.2 Specification

- Measuring range: 0.1~1000.0NTU

- Accuracy: ±5%

- Resolution: 0.1NTU

- Stability: ≤3mV/24 hours

- Output signal: A: 4~20 mA (current loop)B: RS485 (standard Modbus-RTU protocol, device default address: 15)

- Power supply voltage: 5~24V DC (when the output signal is RS485)

- 12~24V DC (when the output signal is 4~20mA)

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Power consumption: ≤0.5W

4.5.3 Dimension

4.5.4 Instructions for use and maintenance

- It can be directly put into water without adding a protective tube, ensuring the long-term stability, reliability and accuracy of the sensor.

- If the water conditions are complex and you want accurate data, you need to wipe the sensor probe frequently.

4.5.5 Calibration

For turbidity calibration, you only need to prepare a solution. You can choose 0NTU, 200NTU, 400NTU, 600NTU, 800NTU, 1000NTU, and then enter the corresponding calibration command.

"AT+CALNTU=0" 0NTU turbidity solution

"AT+CALNTU=2" 200NTU turbidity solution

"AT+CALNTU=4" 400NTU turbidity solution

"AT+CALNTU=6" 600NTU turbidity solution

"AT+CALNTU=8" 800NTU turbidity solution

"AT+CALNTU=10" 1000NTU turbidity solution

4.5.6 Precautions

- To ensure that the electrode measures correctly on the pipeline, avoid bubbles between the measuring cells that may cause data inaccuracy.

- Please check whether the packaging is intact and whether the product model is consistent with the selected model.

- Do not connect the wires with power on. After the wiring is completed and checked, power can be turned on.

- Do not arbitrarily change the components or wires that have been welded at the factory when using the product.

- The sensor is a precision device. When using it, please do not disassemble it by yourself or contact the sensor surface with sharp objects or corrosive liquids to avoid damaging the product.

- Do not power on while connect the cables. Double check the wiring before power on.

4.6 Residual Chlorine Sensor

4.6.1 Specification:

- Power Input: DC7~30

- Power Consumption : 0.19W

- Interface: RS485. 9600 Baud Rate

- CL Range & Resolution:

- CL2ML:0-2mg/L

- CL10ML:0-10mg/L

- Resolution:0.01mg/L

- CL Accuracy: ±5% FS

- Temperature Accuracy: ±0.5 °C

- Working environment:

- Ambient Temperature: 0–50°C

- pH:4-9

- Flow rate: 30L/h~60L/h (flow tank installation)

- IP Rated: IP68

- Max Pressure: 0.6MPa

4.6.2 Mechinical Drawing

4.6.3 Maintenance

- The device itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself, and contact us as soon as possible!

- After using the electrode, please clean the electrode head with clean water and cover it with a protective cover.

- When measuring the device, the measured liquid should flow and the flow rate should be uniform, and there should be no bubbles attached to the measuring end of the device.

- If the electrode diaphragm is attached with dirt and mineral components, the sensitivity will be reduced, and it may not be possible to perform sufficient measurement. Please ensure that the platinum ring is clean.

- The platinum induction ring of a good residual chlorine electrode should always be kept clean and bright. If the platinum ring of the electrode becomes rough or covered with pollutants after measurement, please clean it according to the following method: (For reference) Inorganic pollution: immerse the electrode in 0.1mol/L dilute hydrochloric acid for 15 minutes, gently wipe the platinum ring of the residual chlorine electrode with a cotton swab, and then wash it with tap water.

- Organic or oil pollution: immerse the electrode in tap water with a small amount of detergent, such as dishwashing liquid, and thoroughly clean the sensing surface of the electrode sensor. Gently wipe the platinum ring of the electrode with a cotton swab, then rinse with tap water, and the cleaning is complete. If the platinum ring of the electrode has formed an oxide film, please use toothpaste or 1000-grit fine sandpaper to properly polish the sensing surface, and then clean it with tap water. The platinum ring is connected to the glass, so please handle it carefully when polishing.

The electrode has a service life of about one year, and a new electrode should be replaced in time after aging. - Before the cable plug and the device plug are locked, do not put the plug part into water.

5. Battery & Power Consumption

WQS-CB use ER26500 + SPC1520 battery pack and WQS-CS use 3000mAh Recharable Battery with Solar Panel. See below link for detail information about the battery info and how to replace.

Battery Info & Power Consumption Analyze .

6. FAQ

6.1 External Power Supply Connection (For Battery Depletion/Multi-Sensor Use)

The WQS-CB system includes a 1-to-3 splitter cable for connecting multiple water quality sensors simultaneously. Please be aware that power consumption increases with each additional sensor connected. External power is strongly recommended when:

- The battery is depleted

- Operating 2-3 sensors simultaneously

- For extended monitoring periods

Connection Method:

- Disconnect the battery wires

- Use a power supply with 3.3V voltage and 2A current rating, connecting it to the battery terminals

Recommended Power Specifications: 3.3V/2A external supply

Compatible Power Adapter:

Connector Type:

7. Firmware update

User can change device firmware to:

- Update with new features.

- Fix bugs.

Firmware and changelog can be downloaded from : Firmware download link

Methods to Update Firmware:

- (Recommended way) OTA firmware update via BLE: Instruction.

- Update through UART TTL interface : Instruction.

8. Packing Info

Package Includes:

- WQS-CB/CS Water Quality Sensor Transmitter Node x 1

- External antenna x 1

Dimension and weight:

- Device Size: 13.0 x 5 x 4.5 cm

- Device Weight: 150g

- Package Size / pcs : 14.0 x 8x 5 cm

- Weight / pcs : 180g

9. Sensors

| Sensor Model | Part Number |

|---|---|

| PH Sensor | DR-PH01 |

| EC K1 Sensor | DR-ECK1.0 |

| EC K10 Sensor | DR-ECK10.0 |

| ORP Sensor | DR-ORP1 |

| Dissolved Oxygen Sensor | DR-DO1 |

| Turbidity Sensor | DR-TS1 |

10. Support

- Support is provided Monday to Friday, from 09:00 to 18:00 GMT+8. Due to different timezones we cannot offer live support. However, your questions will be answered as soon as possible in the before-mentioned schedule.

- Provide as much information as possible regarding your enquiry (product models, accurately describe your problem and steps to replicate it etc) and send a mail to support@dragino.com.