SN50v3-LB/LS -- LoRaWAN Sensor Node User Manual

Table of Contents:

- 1. Introduction

- 2. Configure SN50v3-LB/LS to connect to LoRaWAN network

- 2.1 How it works

- 2.2 Quick guide to connect to LoRaWAN server (OTAA)

- 2.3 Uplink Payload

- 2.3.1 Device Status, FPORT=5

- 2.3.2 Working Modes & Sensor Data. Uplink via FPORT=2

- 2.3.2.1 MOD=1 (Default Mode)

- 2.3.2.2 MOD=2 (Distance Mode)

- 2.3.2.3 MOD=3 (3 ADC + I2C)

- 2.3.2.4 MOD=4 (3 x DS18B20)

- 2.3.2.5 MOD=5(Weight Measurement by HX711)

- 2.3.2.6 MOD=6 (Counting Mode)

- 2.3.2.7 MOD=7 (Three interrupt contact modes)

- 2.3.2.8 MOD=8 (3ADC+1DS18B20)

- 2.3.2.9 MOD=9 (3DS18B20+ two Interrupt count mode)

- 2.3.2.10 MOD=10 (PWM input capture and output mode,Since firmware v1.2)

- 2.3.2.11 MOD=11 (TEMP117)(Since firmware V1.3.0)

- 2.3.2.12 MOD=12 (Count+SHT31)(Since firmware V1.3.1)

- 2.3.3 Decode payload

- 2.3.3.1 Battery Info

- 2.3.3.2 Temperature (DS18B20)

- 2.3.3.3 Digital Input

- 2.3.3.4 Analogue Digital Converter (ADC)

- 2.3.3.5 Digital Interrupt

- 2.3.3.6 I2C Interface (SHT20 & SHT31)

- 2.3.3.7 Distance Reading

- 2.3.3.8 Ultrasonic Sensor

- 2.3.3.9 Battery Output - BAT pin

- 2.3.3.10 +5V Output

- 2.3.3.11 BH1750 Illumination Sensor

- 2.3.3.12 PWM MOD

- 2.3.3.13 Working MOD

- 2.4 Payload Decoder file

- 2.5 Frequency Plans

- 3. Configure SN50v3-LB/LS

- 4. Battery & Power Cons

- 5. OTA Firmware update

- 6. Developer Guide

- 7. FAQ

- 8. Order Info

- 9. Packing Info

- 10. Support

1. Introduction

1.1 What is SN50v3-LB/LS LoRaWAN Generic Node

SN50V3-LB/LS LoRaWAN Sensor Node is a Long Range LoRa Sensor Node. It is designed for outdoor use and powered by 8500mAh Li/SOCl2 battery or solar powered + Li-ion battery for long term use.SN50V3-LB/LS is designed to facilitate developers to quickly deploy industrial level LoRa and IoT solutions. It help users to turn the idea into a practical application and make the Internet of Things a reality. It is easy to program, create and connect your things everywhere.

SN50V3-LB/LS wireless part is based on SX1262 allows the user to send data and reach extremely long ranges at low data-rates.It provides ultra-long range spread spectrum communication and high interference immunity whilst minimising current consumption.It targets professional wireless sensor network applications such as irrigation systems, smart metering, smart cities, and so on.

SN50V3-LB/LS has a powerful 48Mhz ARM microcontroller with 256KB flash and 64KB RAM. It has multiplex I/O pins to connect to different sensors.

SN50V3-LB/LS has a built-in BLE module, user can configure the sensor remotely via Mobile Phone. It also support OTA upgrade via private LoRa protocol for easy maintaining.

SN50V3-LB/LS is the 3rd generation of LSN50 series generic sensor node from Dragino. It is an open source project and has a mature LoRaWAN stack and application software. User can use the pre-load software for their IoT projects or easily customize the software for different requirements.

1.2 Features

- LoRaWAN 1.0.3 Class A

- Ultra-low power consumption

- Open-Source hardware/software

- Bands: CN470/EU433/KR920/US915/EU868/AS923/AU915/IN865

- Support Bluetooth v5.1 and LoRaWAN remote configure

- Support wireless OTA update firmware

- Uplink on periodically

- Downlink to change configure

- 8500mAh Li/SOCl2 Battery (SN50v3-LB)

- Solar panel + 3000mAh Li-ion battery (SN50v3-LS)

1.3 Specification

Common DC Characteristics:

- Supply Voltage: Built-in Battery , 2.5v ~ 3.6v

- Operating Temperature: -40 ~ 85°C

I/O Interface:

- Battery output (2.6v ~ 3.6v depends on battery)

- +5v controllable output

- 3 x Interrupt or Digital IN/OUT pins

- 3 x one-wire interfaces

- 1 x UART Interface

- 1 x I2C Interface

LoRa Spec:

- Frequency Range, Band 1 (HF): 862 ~ 1020 Mhz

- Max +22 dBm constant RF output vs.

- RX sensitivity: down to -139 dBm.

- Excellent blocking immunity

Battery:

- Li/SOCI2 un-chargeable battery

- Capacity: 8500mAh

- Self-Discharge: <1% / Year @ 25°C

- Max continuously current: 130mA

- Max boost current: 2A, 1 second

Power Consumption

- Sleep Mode: 5uA @ 3.3v

- LoRa Transmit Mode: 125mA @ 20dBm, 82mA @ 14dBm

1.4 Sleep mode and working mode

Deep Sleep Mode: Sensor doesn't have any LoRaWAN activate. This mode is used for storage and shipping to save battery life.

Working Mode: In this mode, Sensor will work as LoRaWAN Sensor to Join LoRaWAN network and send out sensor data to server. Between each sampling/tx/rx periodically, sensor will be in IDLE mode), in IDLE mode, sensor has the same power consumption as Deep Sleep mode.

1.5 Button & LEDs

| Behavior on ACT | Function | Action |

|---|---|---|

1~3s 1~3s | Send an uplink | If sensor is already Joined to LoRaWAN network, sensor will send an uplink packet, blue led will blink once. |

>3s >3s | Active Device | Green led will fast blink 5 times, device will enter OTA mode for 3 seconds. And then start to JOIN LoRaWAN network. |

x5 x5 | Deactivate Device | Red led will solid on for 5 seconds. Means device is in Deep Sleep Mode. |

1.6 BLE connection

SN50v3-LB/LS supports BLE remote configure.

BLE can be used to configure the parameter of sensor or see the console output from sensor. BLE will be only activate on below case:

- Press button to send an uplink

- Press button to active device.

- Device Power on or reset.

If there is no activity connection on BLE in 60 seconds, sensor will shut down BLE module to enter low power mode.

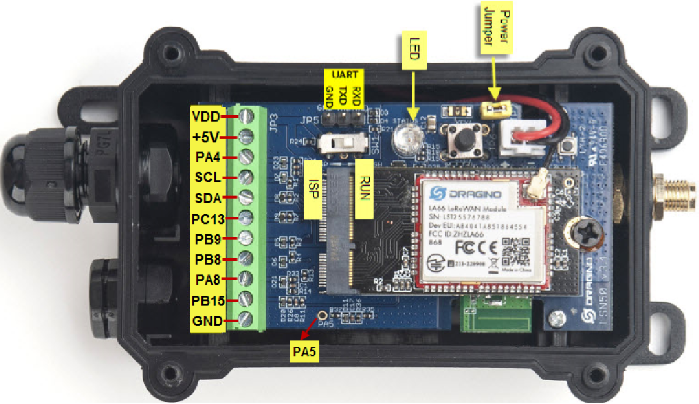

1.7 Pin Definitions

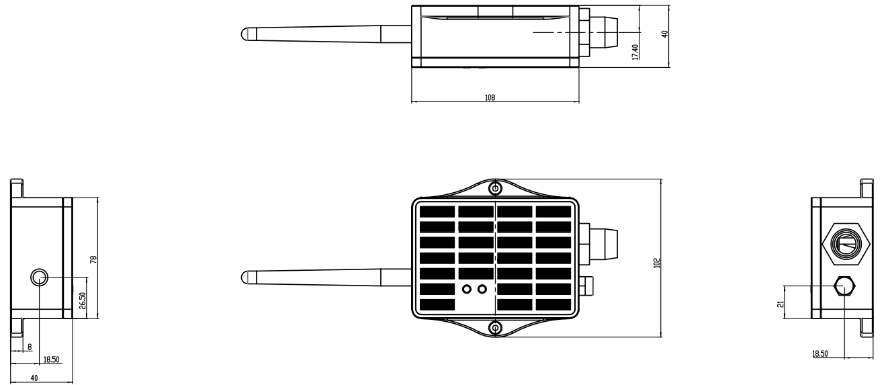

1.8 Mechanical

1.8.1 for LB version

1.8.2 for LS version

1.9 Hole Option

SN50v3-LB/LS has different hole size options for different size sensor cable. The options provided are M12, M16 and M20. The definition is as below:

2. Configure SN50v3-LB/LS to connect to LoRaWAN network

2.1 How it works

The SN50v3-LB/LS is configured as LoRaWAN OTAA Class A mode by default. It has OTAA keys to join LoRaWAN network. To connect a local LoRaWAN network, you need to input the OTAA keys in the LoRaWAN IoT server and press the button to activate the SN50v3-LB/LS. It will automatically join the network via OTAA and start to send the sensor value. The default uplink interval is 20 minutes.

2.2 Quick guide to connect to LoRaWAN server (OTAA)

Following is an example for how to join the TTN v3 LoRaWAN Network. Below is the network structure; we use the LPS8v2 as a LoRaWAN gateway in this example.

The LPS8v2 is already set to connected to TTN network , so what we need to now is configure the TTN server.

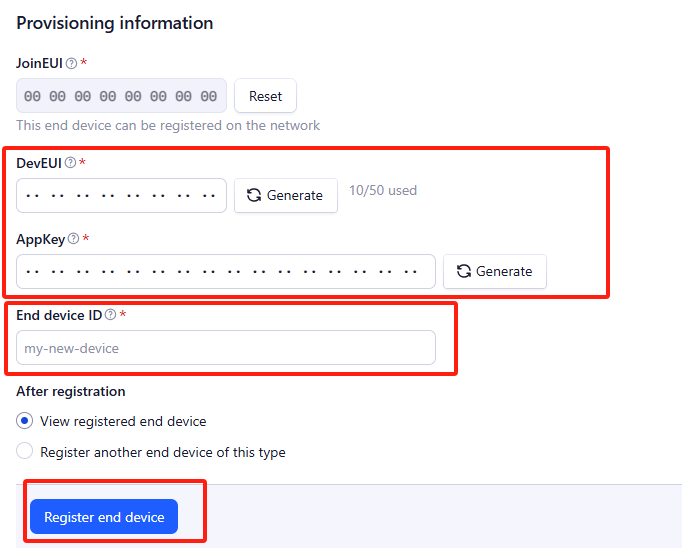

Step 1: Create a device in TTN with the OTAA keys from SN50v3-LB/LS.

Each SN50v3-LB/LS is shipped with a sticker with the default device EUI as below:

You can enter this key in the LoRaWAN Server portal. Below is TTN screen shot:

Create the application.

Add devices to the created Application.

Enter end device specifics manually.

Add DevEUI and AppKey.

Customize a platform ID for the device.

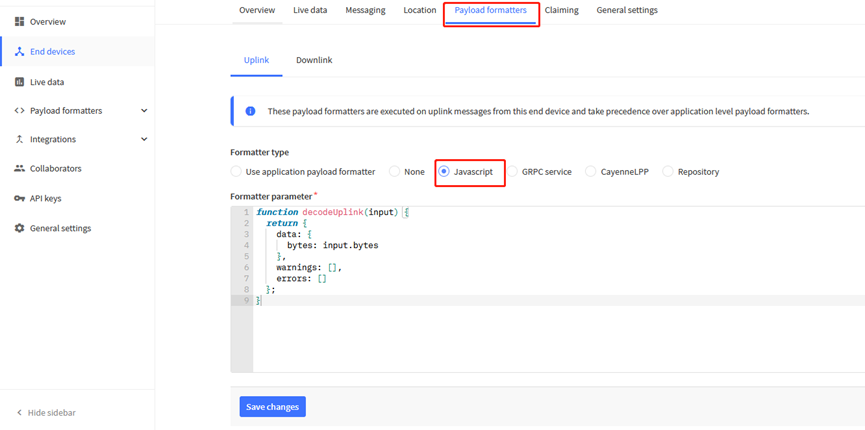

Step 2: Add decoder.

In TTN, user can add a custom payload so it shows friendly reading.

Click this link to get the decoder: https://github.com/dragino/dragino-end-node-decoder/tree/main/

Below is TTN screen shot:

Step 3: Activate SN50v3-LB/LS

Press the button for 5 seconds to activate the SN50v3-LB/LS.

Green led will fast blink 5 times, device will enter OTA mode for 3 seconds. And then start to JOIN LoRaWAN network. Green led will solidly turn on for 5 seconds after joined in network.

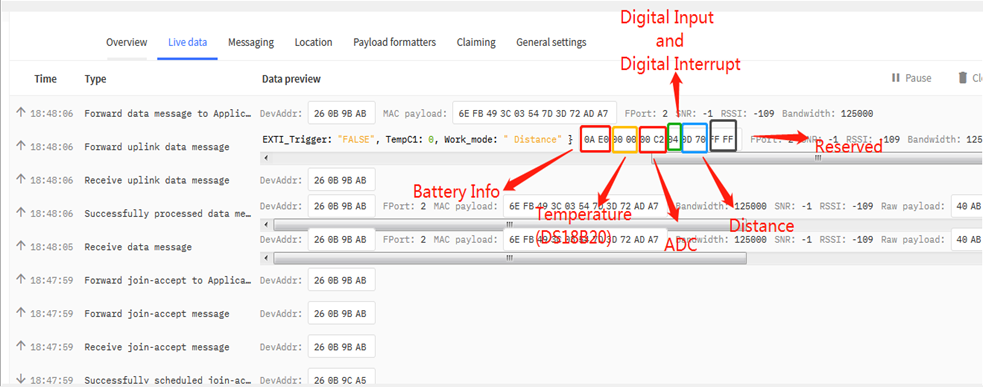

After join success, it will start to upload messages to TTN and you can see the messages in the panel.

2.3 Uplink Payload

2.3.1 Device Status, FPORT=5

Users can use the downlink command(0x26 01) to ask SN50v3-LB/LS to send device configure detail, include device configure status. SN50v3-LB/LS will uplink a payload via FPort=5 to server.

The Payload format is as below.

| Device Status (FPORT=5) | |||||

| Size (bytes) | 1 | 2 | 1 | 1 | 2 |

| Value | Sensor Model | Firmware Version | Frequency Band | Sub-band | BAT |

Example parse in TTNv3

Sensor Model: For SN50v3-LB/LS, this value is 0x1C

Firmware Version: 0x0100, Means: v1.0.0 version

Frequency Band:

0x01: EU868

0x02: US915

0x03: IN865

0x04: AU915

0x05: KZ865

0x06: RU864

0x07: AS923

0x08: AS923-1

0x09: AS923-2

0x0a: AS923-3

0x0b: CN470

0x0c: EU433

0x0d: KR920

0x0e: MA869

Sub-Band:

AU915 and US915:value 0x00 ~ 0x08

CN470: value 0x0B ~ 0x0C

Other Bands: Always 0x00

Battery Info:

Check the battery voltage.

Ex1: 0x0B45 = 2885mV

Ex2: 0x0B49 = 2889mV

2.3.2 Working Modes & Sensor Data. Uplink via FPORT=2

SN50v3-LB/LS has different working mode for the connections of different type of sensors. This section describes these modes. Use can use the AT Command AT+MOD to set SN50v3-LB/LS to different working modes.

For example:

AT+MOD=2 // will set the SN50v3 to work in MOD=2 distance mode which target to measure distance via Ultrasonic Sensor.

Important Notice:

1. Some working modes has payload more than 12 bytes, The US915/AU915/AS923 frequency bands' definition has maximum 11 bytes in DR0. Server sides will see NULL payload while SN50v3-LB/LS transmit in DR0 with 12 bytes payload.

2. All modes share the same Payload Explanation from HERE.

3. By default, the device will send an uplink message every 20 minutes.

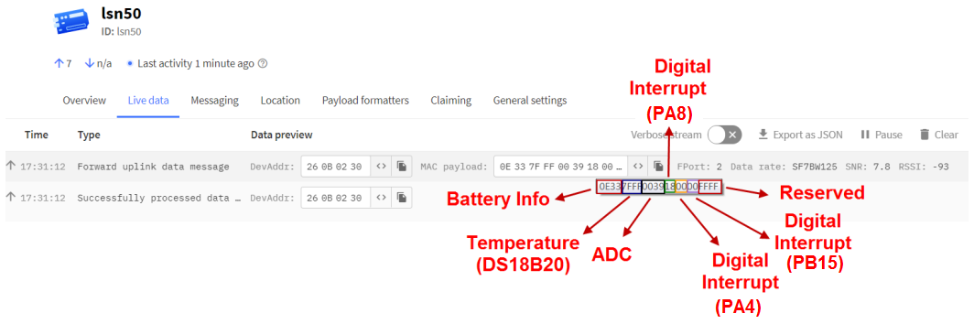

2.3.2.1 MOD=1 (Default Mode)

In this mode, uplink payload includes in total 11 bytes. Uplink packets use FPORT=2.

| Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 |

| Value | Bat | Temperature(DS18B20)(PC13) | ADC(PA4) | Digital in(PB15)&Digital Interrupt(PA8) | Temperature(SHT20 or SHT31 or BH1750 Illumination Sensor) | Humidity(SHT20 or SHT31) |

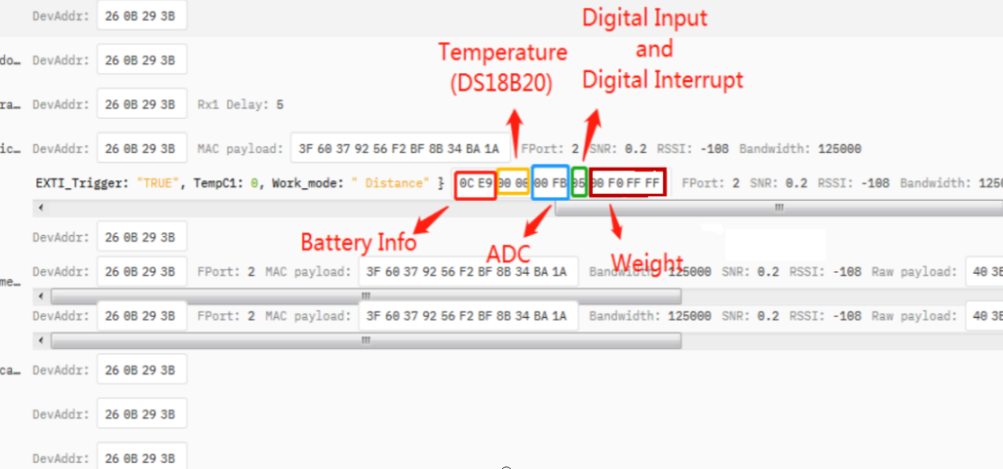

2.3.2.2 MOD=2 (Distance Mode)

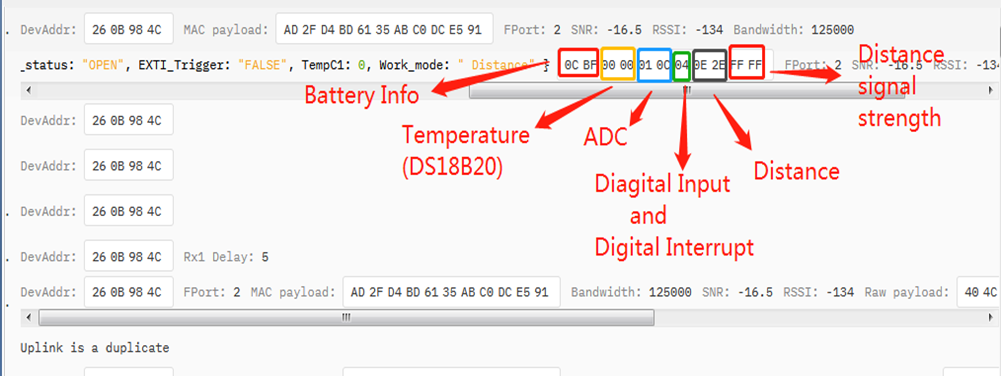

This mode is target to measure the distance. The payload of this mode is totally 11 bytes. The 8th and 9th bytes is for the distance.

| Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 |

| Value | BAT | Temperature(DS18B20)(PC13) | ADC(PA4) | Digital in(PB15) & Digital Interrupt(PA8) | Distance measure by: 1) LIDAR-Lite V3HP | Reserved |

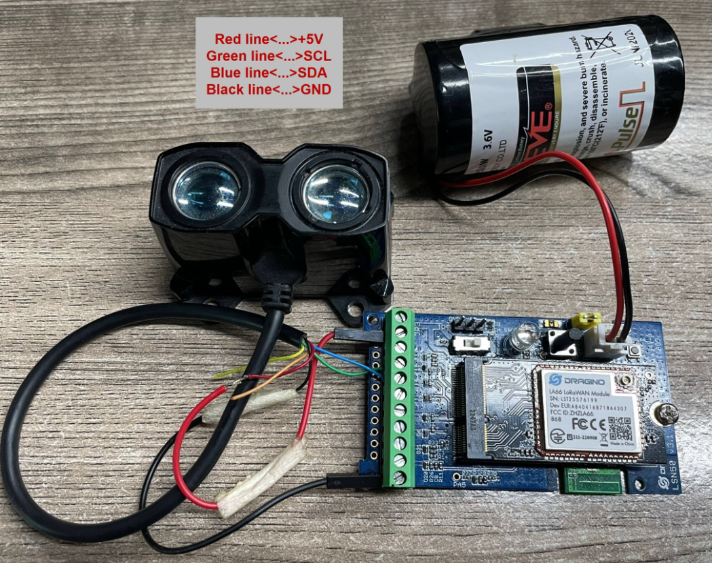

Connection of LIDAR-Lite V3HP:

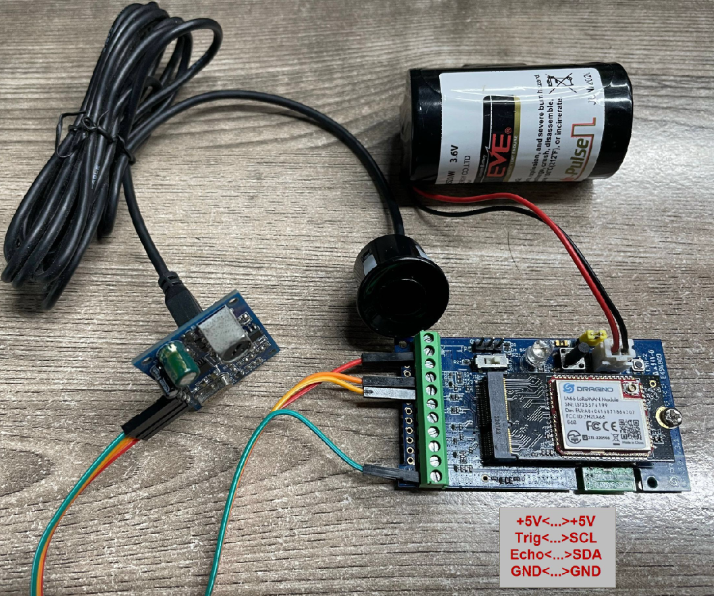

Connection to Ultrasonic Sensor:

Need to remove R1 and R2 resistors to get low power,otherwise there will be 240uA standby current.

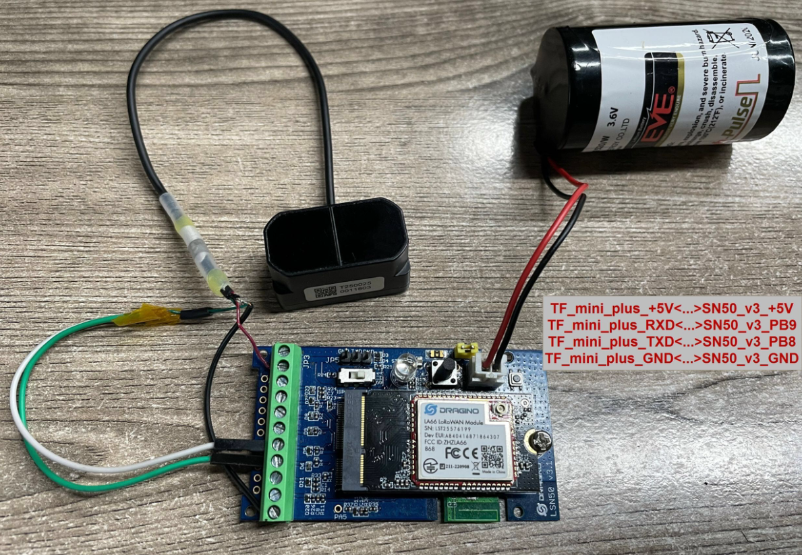

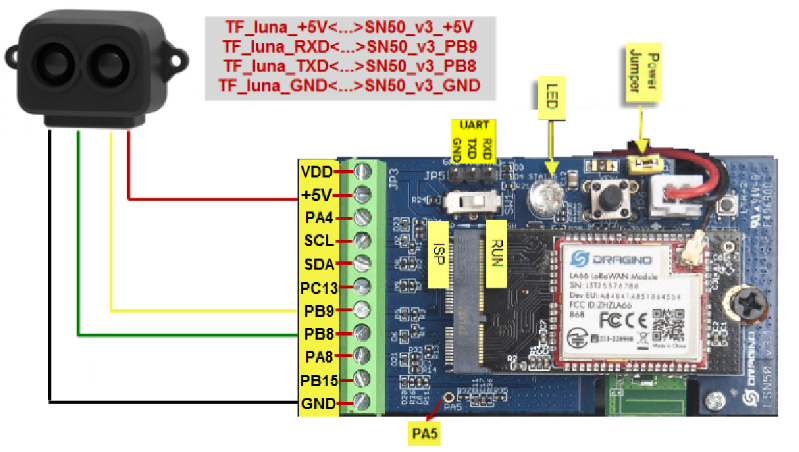

For the connection to TF-Mini or TF-Luna , MOD2 payload is as below:

| Size(bytes) | 2 | 2 | 1 | 2 | 2 | 2 |

| Value | BAT | Temperature(DS18B20)(PC13) | Digital in(PB15) & Digital Interrupt(PA8) | ADC(PA4) | Distance measure by:1)TF-Mini plus LiDAR | Distance signal strength |

Connection to TF-Mini plus LiDAR(UART version):

Need to remove R3 and R4 resistors to get low power,otherwise there will be 400uA standby current.

Connection to TF-Luna LiDAR (UART version):

Need to remove R3 and R4 resistors to get low power,otherwise there will be 400uA standby current.

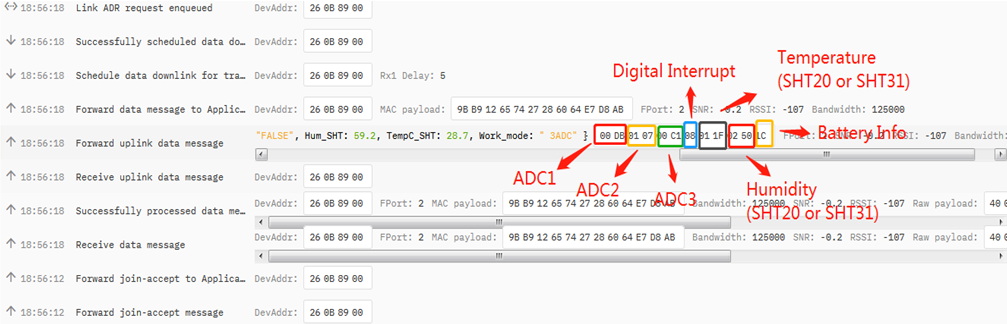

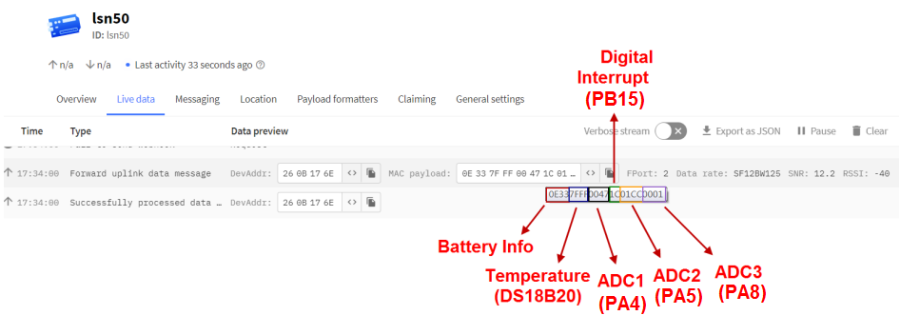

2.3.2.3 MOD=3 (3 ADC + I2C)

This mode has total 12 bytes. Include 3 x ADC + 1x I2C

Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 | 1 |

|---|---|---|---|---|---|---|---|

| Value | ADC1(PA4) | ADC2(PA5) | ADC3(PA8) | Digital Interrupt(PB15) | Temperature(SHT20 or SHT31 or BH1750 Illumination Sensor) | Humidity(SHT20 or SHT31) | Bat |

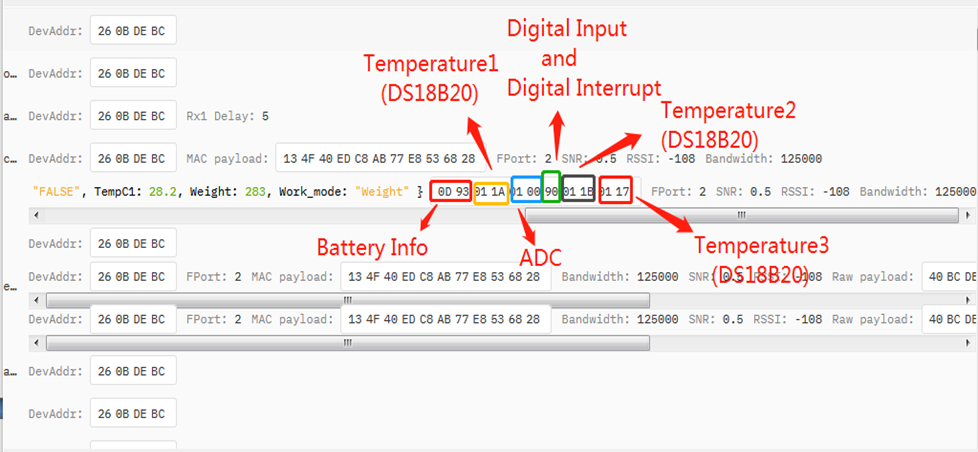

2.3.2.4 MOD=4 (3 x DS18B20)

This mode has total 11 bytes. As shown below:

| Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 |

| Value | BAT | Temperature1(DS18B20)(PC13) | ADC(PA4) | Digital in(PB15) & Digital Interrupt(PA8) | Temperature2(DS18B20) (PB9) | Temperature3(DS18B20)(PB8) |

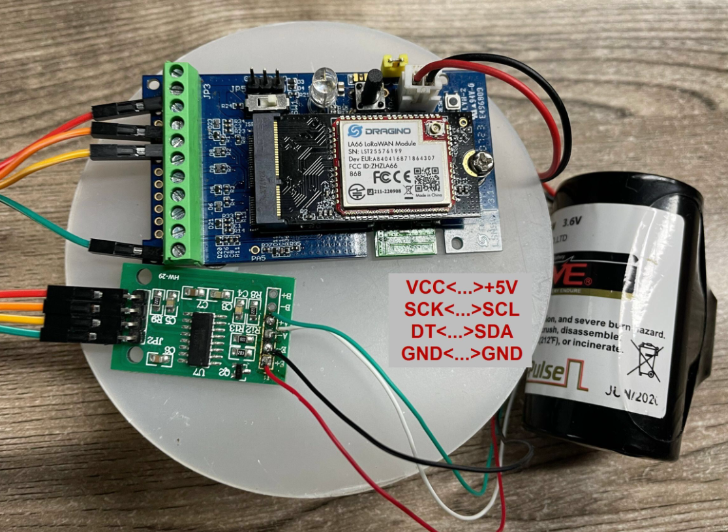

2.3.2.5 MOD=5(Weight Measurement by HX711)

Each HX711 need to be calibrated before used. User need to do below two steps:

- Zero calibration. Don't put anything on load cell and run AT+WEIGRE to calibrate to Zero gram.

- Adjust calibration factor (default value 400): Put a known weight thing on load cell and run AT+WEIGAP to adjust the Calibration Factor.

Weight has 4 bytes, the unit is g.

For example:

AT+GETSENSORVALUE =0

Response: Weight is 401 g

Check the response of this command and adjust the value to match the real value for thing.

Size(bytes) | 2 | 2 | 2 | 1 | 4 |

|---|---|---|---|---|---|

| Value | BAT | Temperature(DS18B20)(PC13) | ADC(PA4) | Digital in(PB15) & Digital Interrupt(PA8) | Weight |

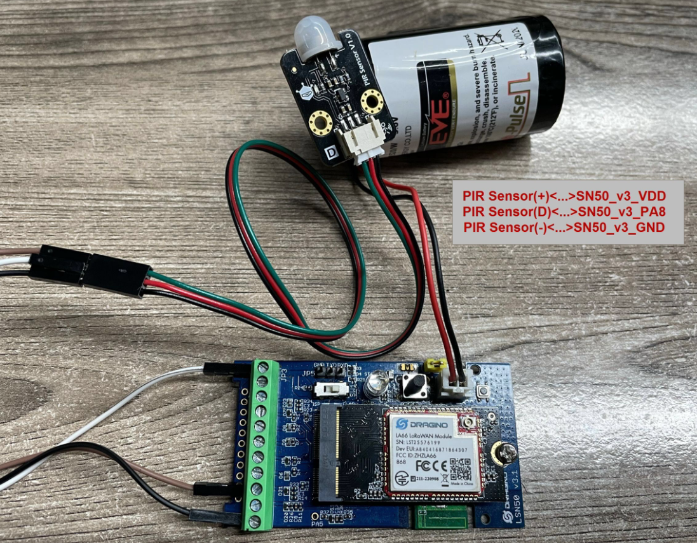

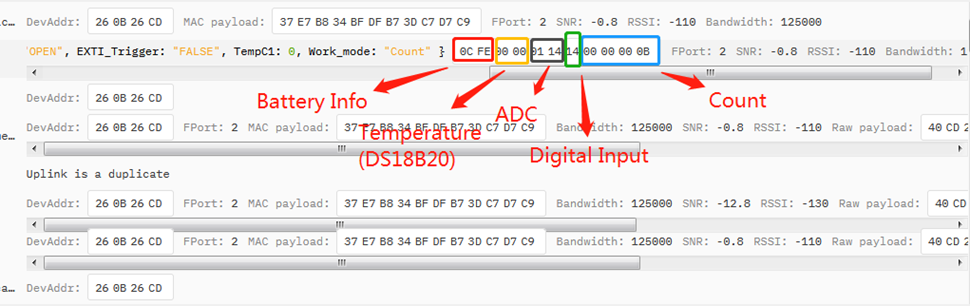

2.3.2.6 MOD=6 (Counting Mode)

In this mode, the device will work in counting mode. It counts the interrupt on the interrupt pins and sends the count on TDC time.

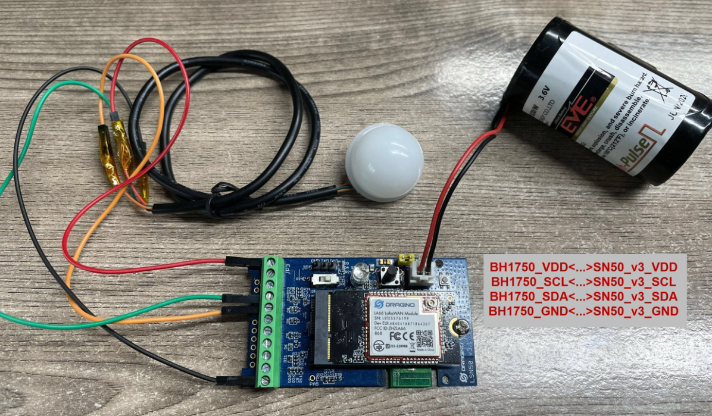

Connection is as below. The PIR sensor is a count sensor, it will generate interrupt when people come close or go away. User can replace the PIR sensor with other counting sensors.

Note: LoRaWAN wireless transmission will infect the PIR sensor. Which cause the counting value increase +1 for every uplink. User can change PIR sensor or put sensor away of the SN50_v3 to avoid this happen.

| Size(bytes) | 2 | 2 | 2 | 1 | 4 |

|---|---|---|---|---|---|

| Value | BAT | Temperature(DS18B20)(PC13) | ADC(PA4) | Digital in(PB15) | Count(PA8) |

2.3.2.7 MOD=7 (Three interrupt contact modes)

Size(bytes) | 2 | 2 | 2 | 1 | 1 | 1 | 2 |

|---|---|---|---|---|---|---|---|

| Value | BAT | Temperature(DS18B20) | ADC(PA5) | Digital Interrupt1(PA8) | Digital Interrupt2(PA4) | Digital Interrupt3(PB15) | Reserved |

2.3.2.8 MOD=8 (3ADC+1DS18B20)

Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 |

|---|---|---|---|---|---|---|

| Value | BAT | Temperature(DS18B20) | ADC1(PA4) | Digital Interrupt(PB15) | ADC2(PA5) | ADC3(PA8) |

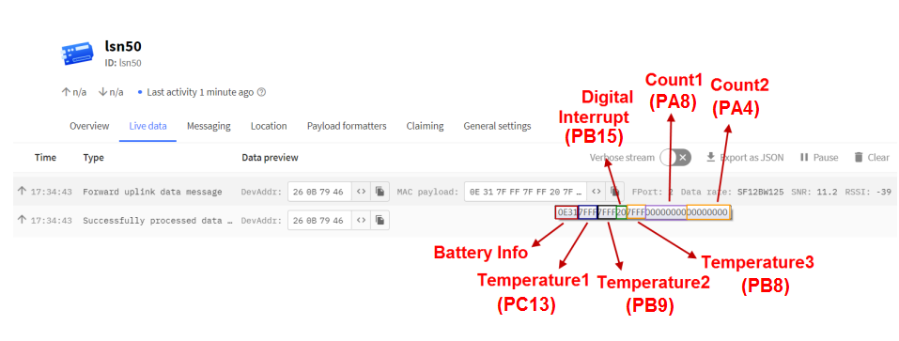

2.3.2.9 MOD=9 (3DS18B20+ two Interrupt count mode)

Size(bytes) | 2 | 2 | 2 | 1 | 2 | 4 | 4 |

|---|---|---|---|---|---|---|---|

| Value | BAT | Temperature | Temperature2 | Digital Interrupt | Temperature3 | Count1(PA8) | Count2(PA4) |

The newly added AT command is issued correspondingly:

AT+INTMOD1 PA8 pin: Corresponding downlink: 06 00 00 xx

AT+INTMOD2 PA4 pin: Corresponding downlink: 06 00 01 xx

AT+INTMOD3 PB15 pin: Corresponding downlink: 06 00 02 xx

AT+SETCNT=aa,bb

When AA is 1, set the count of PA8 pin to BB Corresponding downlink:09 01 bb bb bb bb

When AA is 2, set the count of PA4 pin to BB Corresponding downlink:09 02 bb bb bb bb

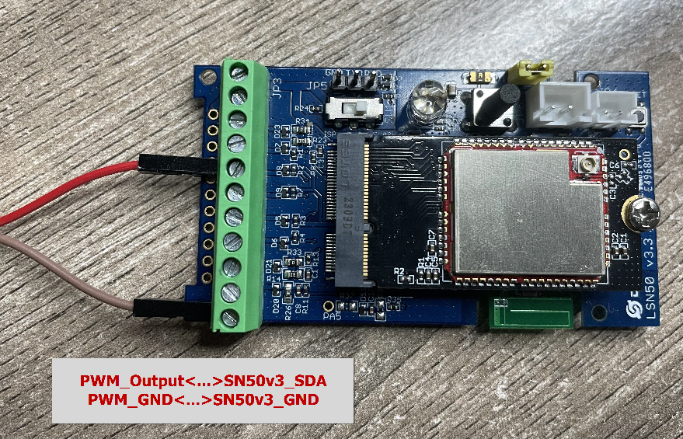

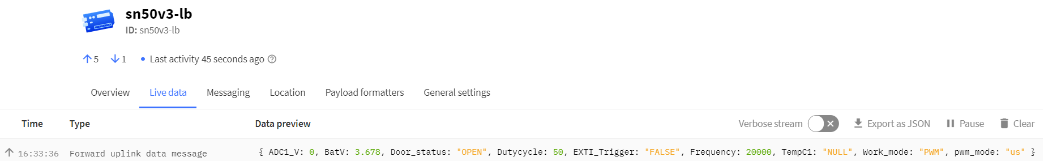

2.3.2.10 MOD=10 (PWM input capture and output mode,Since firmware v1.2)

Note: Firmware not release, contact Dragino for testing.

In this mode, the uplink can perform PWM input capture, and the downlink can perform PWM output.

It should be noted when using PWM mode.

2.3.2.10.a Uplink, PWM input capture

| Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 |

| Value | Bat | Temperature(DS18B20)(PC13) | ADC(PA4) | PWM_Setting | Pulse period | Duration of high level |

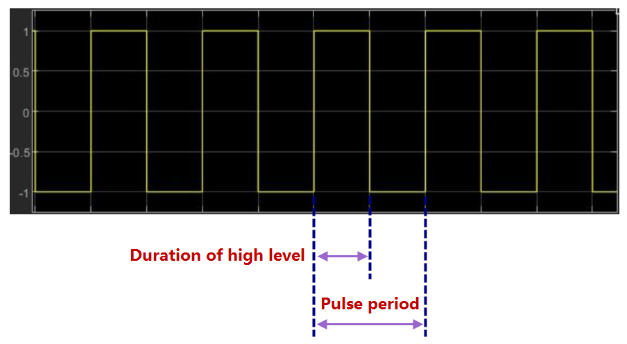

When the device detects the following PWM signal ,decoder will converts the pulse period and high-level duration to frequency and duty cycle.

Frequency:

If AT+PWMSET=0, Frequency= 1000000/Pulse period(HZ);

If AT+PWMSET=1, Frequency= 1000/Pulse period(HZ);

Duty cycle:

Duty cycle= Duration of high level/ Pulse period*100 (%).

2.3.2.10.b Uplink, PWM output

AT+PWMOUT=a,b,c

a is the time delay of the output, the unit is ms.

b is the output frequency, the unit is HZ.

c is the duty cycle of the output, the unit is %.

Downlink: 0B 01 bb cc aa

aa is the time delay of the output, the unit is ms.

bb is the output frequency, the unit is HZ.

cc is the duty cycle of the output, the unit is %.

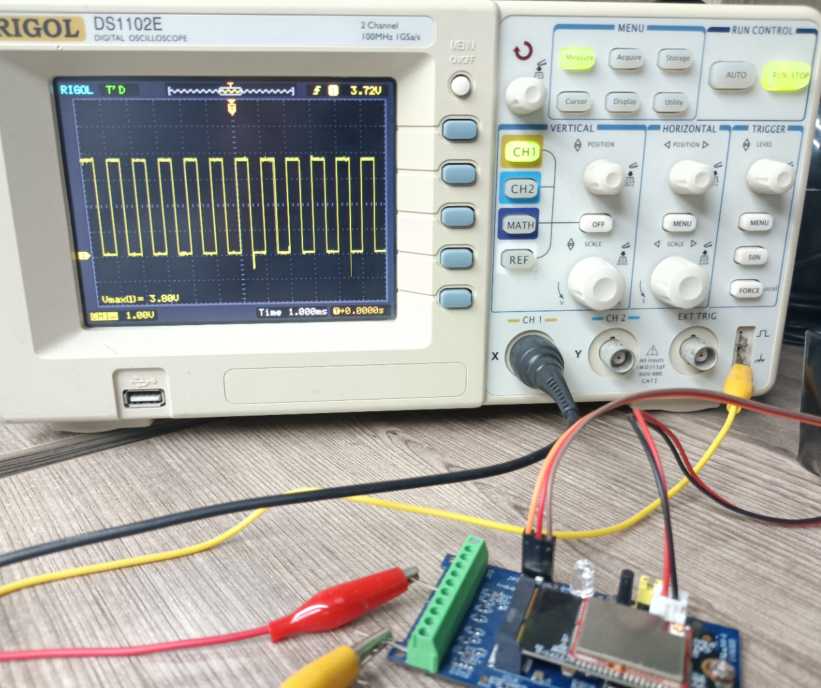

For example, send a AT command: AT+PWMOUT=65535,1000,50 The PWM is always out, the frequency is 1000HZ, and the duty cycle is 50.

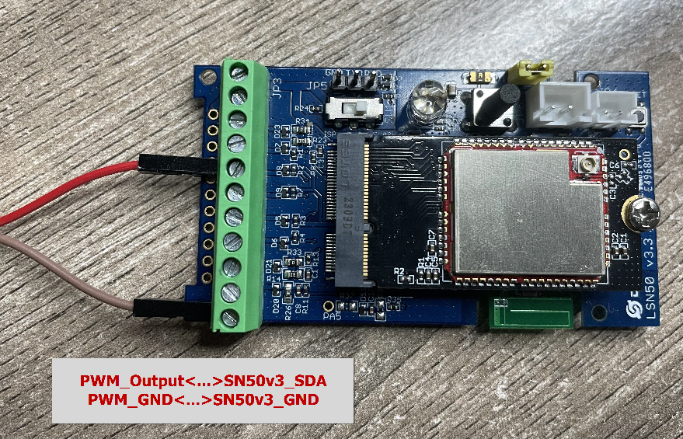

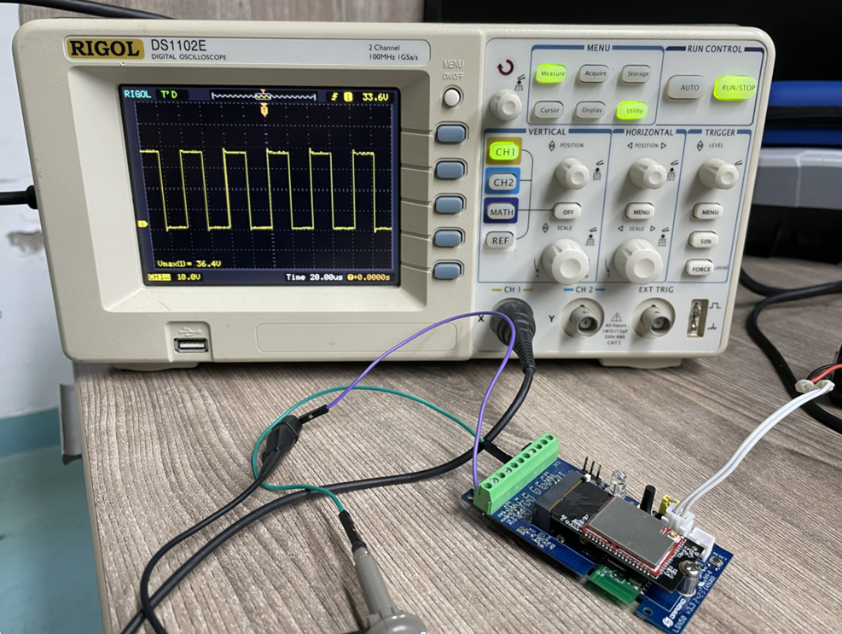

The oscilloscope displays as follows:

2.3.2.10.c Downlink, PWM output

Downlink: 0B xx xx xx yy zz zz

xx xx xx is the output frequency, the unit is HZ.

yy is the duty cycle of the output, the unit is %.

zz zz is the time delay of the output, the unit is ms.

For example, send a downlink command: 0B 00 61 A8 32 13 88, the frequency is 25KHZ, the duty cycle is 50, and the output time is 5 seconds.

The oscilloscope displays as follows:

2.3.2.11 MOD=11 (TEMP117)(Since firmware V1.3.0)

In this mode, uplink payload includes in total 11 bytes. Uplink packets use FPORT=2.

| Size(bytes) | 2 | 2 | 2 | 1 | 2 | 2 |

| Value | Bat | Temperature(DS18B20)(PC13) | ADC(PA4) | Digital in(PB15)&Digital Interrupt(PA8) | Temperature | Reserved position, meaningless |

Connection:

2.3.2.12 MOD=12 (Count+SHT31)(Since firmware V1.3.1)

This mode has total 11 bytes. As shown below:

| Size(bytes) | 2 | 2 | 2 | 1 | 4 |

|---|---|---|---|---|---|

| Value | BAT | Temperature_SHT31 | Humidity_SHT31 | Digital in(PB15) | Count(PA8) |

Wiring example:

2.3.3 Decode payload

While using TTN V3 network, you can add the payload format to decode the payload.

The payload decoder function for TTN V3 are here:

SN50v3-LB/LS TTN V3 Payload Decoder: https://github.com/dragino/dragino-end-node-decoder

2.3.3.1 Battery Info

Check the battery voltage for SN50v3-LB/LS.

Ex1: 0x0B45 = 2885mV

Ex2: 0x0B49 = 2889mV

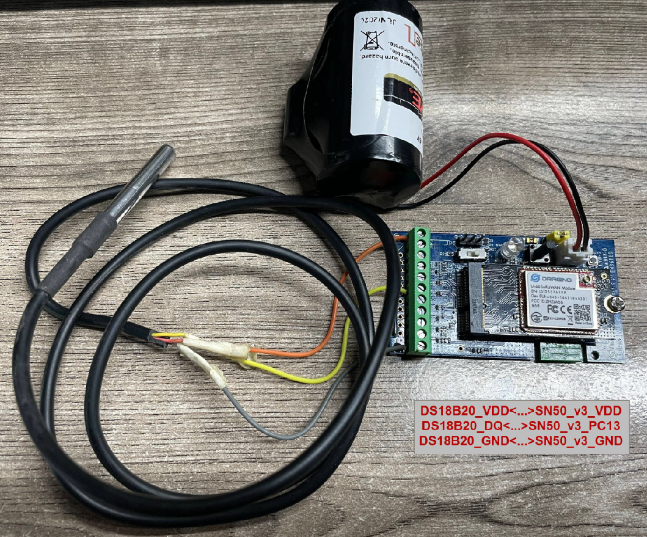

2.3.3.2 Temperature (DS18B20)

If there is a DS18B20 connected to PC13 pin. The temperature will be uploaded in the payload.

More DS18B20 can check the 3 DS18B20 mode

Connection:

Example:

If payload is: 0105H: (0105 & 8000 == 0), temp = 0105H /10 = 26.1 degree

If payload is: FF3FH : (FF3F & 8000 == 1) , temp = (FF3FH - 65536)/10 = -19.3 degrees.

(FF3F & 8000:Judge whether the highest bit is 1, when the highest bit is 1, it is negative)

2.3.3.3 Digital Input

The digital input for pin PB15,

- When PB15 is high, the bit 1 of payload byte 6 is 1.

- When PB15 is low, the bit 1 of payload byte 6 is 0.

When the digital interrupt pin is set to AT+INTMODx=0, this pin is used as a digital input pin.

Note: The maximum voltage input supports 3.6V.

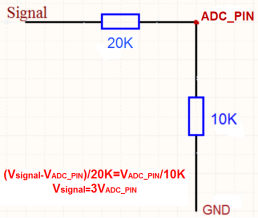

2.3.3.4 Analogue Digital Converter (ADC)

The measuring range of the ADC is only about 0.1V to 1.1V The voltage resolution is about 0.24mv.

When the measured output voltage of the sensor is not within the range of 0.1V and 1.1V, the output voltage terminal of the sensor shall be divided The example in the following figure is to reduce the output voltage of the sensor by three times If it is necessary to reduce more times, calculate according to the formula in the figure and connect the corresponding resistance in series.

Note: If the ADC type sensor needs to be powered by SN50_v3, it is recommended to use +5V to control its switch.Only sensors with low power consumption can be powered with VDD.

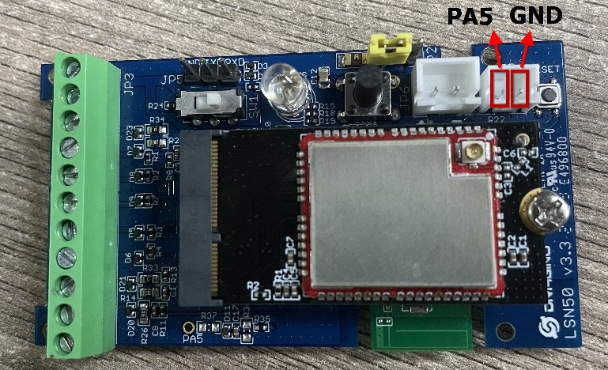

The position of PA5 on the hardware after LSN50 v3.3 is changed to the position shown in the figure below, and the collected voltage becomes one-sixth of the original.

2.3.3.5 Digital Interrupt

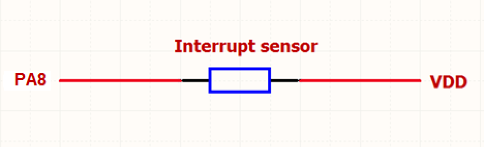

Digital Interrupt refers to pin PA8, and there are different trigger methods. When there is a trigger, the SN50v3-LB/LS will send a packet to the server.

Interrupt connection method:

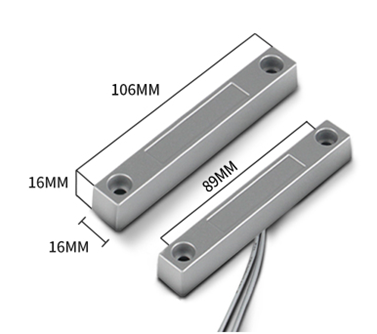

Example to use with door sensor :

The door sensor is shown at right. It is a two wire magnetic contact switch used for detecting the open/close status of doors or windows.

When the two pieces are close to each other, the 2 wire output will be short or open (depending on the type), while if the two pieces are away from each other, the 2 wire output will be the opposite status. So we can use SN50v3-LB/LS interrupt interface to detect the status for the door or window.

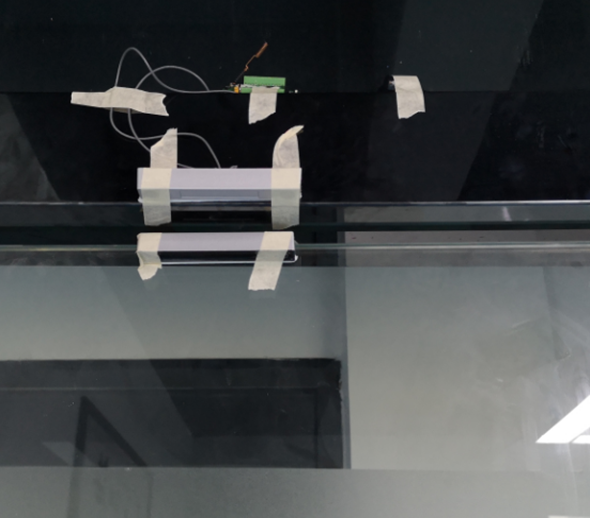

Below is the installation example:

Fix one piece of the magnetic sensor to the door and connect the two pins to SN50v3-LB/LS as follows:

One pin to SN50v3-LB/LS's PA8 pin

The other pin to SN50v3-LB/LS's VDD pin

Install the other piece to the door. Find a place where the two pieces will be close to each other when the door is closed. For this particular magnetic sensor, when the door is closed, the output will be short, and PA8 will be at the VCC voltage.

Door sensors have two types: NC (Normal close) and NO (normal open). The connection for both type sensors are the same. But the decoding for payload are reverse, user need to modify this in the IoT Server decoder.

When door sensor is shorted, there will extra power consumption in the circuit, the extra current is 3v3/R14 = 3v3/1Mohm = 3uA which can be ignored.

The above photos shows the two parts of the magnetic switch fitted to a door.

The software by default uses the falling edge on the signal line as an interrupt. We need to modify it to accept both the rising edge (0v --> VCC , door close) and the falling edge (VCC --> 0v , door open) as the interrupt.

The command is:

AT+INTMOD1=1 // (more info about INMOD please refer AT Command Manual. )

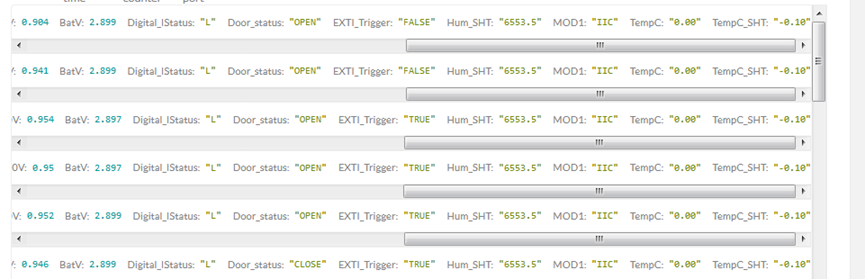

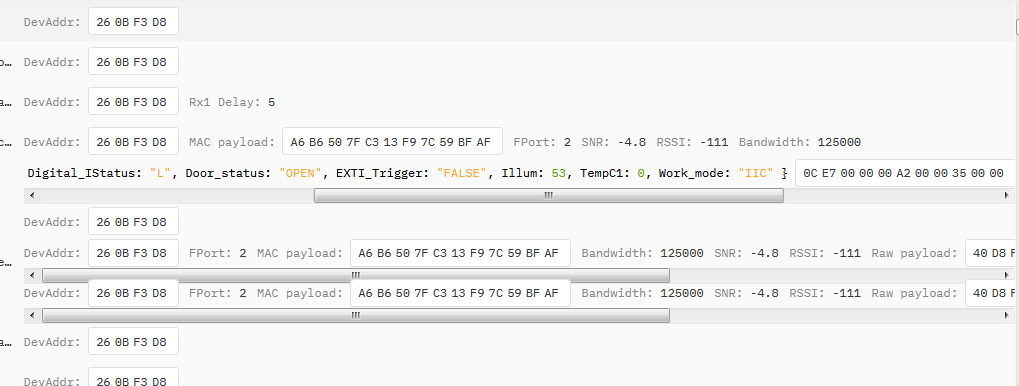

Below shows some screen captures in TTN V3:

Application in different modes:

- In MOD=1, user can use byte 6 to see the status for door open or close. TTN V3 decoder is as below:

door= (bytes[6] & 0x80)? "CLOSE":"OPEN";

- In MOD=7, there are three interrupt pins in effect.

See the AT+INTMODx command explained to set the three pin interrupt modes.

As you can see from the byte parsing table of pattern 7, the seventh byte of the original load is used to display the PA8 pin interrupt flag and status, the eighth byte of the original load is used to display the PA4 pin interrupt flag and status, and the ninth byte of the original load is used to display the PB15 pin interrupt flag and status.

TTN V3 decoder is as below:

Note: mode in decoding is sorted from 0, so it corresponds to the actual working mode AT+MOD=7.

Interrupt flag: "EXTI1/2/3_Trigger", indicates whether the uplink packet is generated by an interrupt on the PA8/PA4/PB15 pin.

Interrupt status: "EXTI1/2/3_Status", Displays the status of the interrupt sensors connected to the PA4/PA8/PB15 interrupt pins when the packet is uplinked.

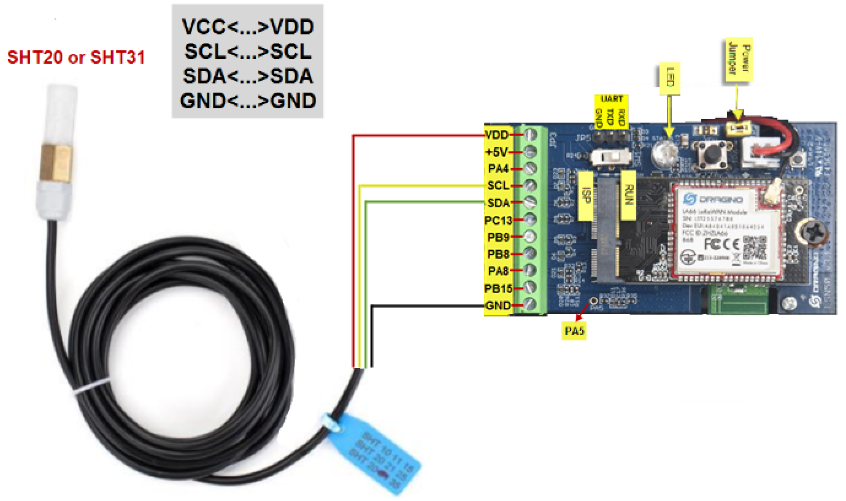

2.3.3.6 I2C Interface (SHT20 & SHT31)

The SDA and SCK are I2C interface lines. You can use these to connect to an I2C device and get the sensor data.

We have made an example to show how to use the I2C interface to connect to the SHT20/ SHT31 Temperature and Humidity Sensor.

Notice: Different I2C sensors have different I2C commands set and initiate process, if user want to use other I2C sensors, User need to re-write the source code to support those sensors. SHT20/ SHT31 code in SN50v3-LB/LS will be a good reference.

Below is the connection to SHT20/ SHT31. The connection is as below:

The device will be able to get the I2C sensor data now and upload to IoT Server.

Convert the read byte to decimal and divide it by ten.

Example:

Temperature: Read:0116(H) = 278(D) Value: 278 /10=27.8℃;

Humidity: Read:0248(H)=584(D) Value: 584 / 10=58.4, So 58.4%

If you want to use other I2C device, please refer the SHT20 part source code as reference.

2.3.3.7 Distance Reading

Refer Ultrasonic Sensor section.

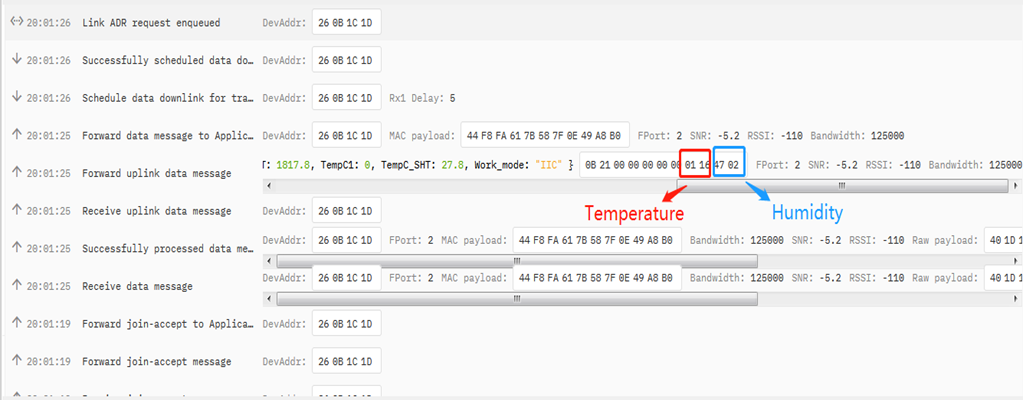

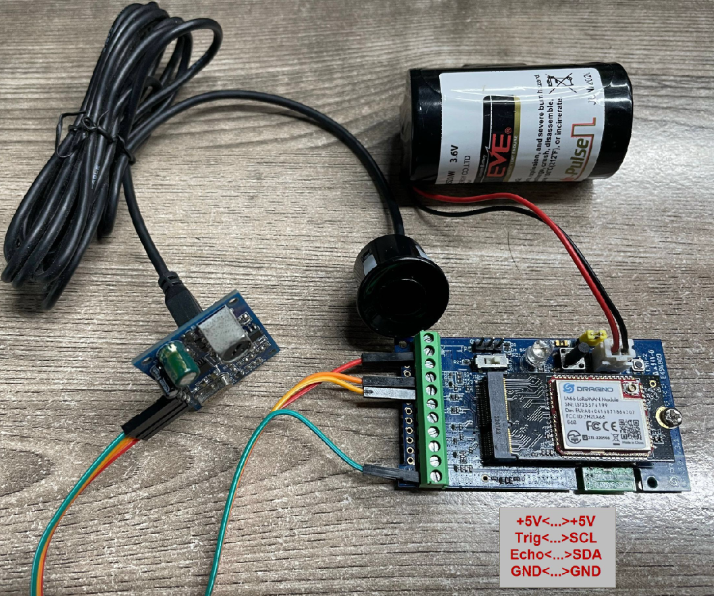

2.3.3.8 Ultrasonic Sensor

This Fundamental Principles of this sensor can be found at this link: https://wiki.dfrobot.com/Weather_-_proof_Ultrasonic_Sensor_with_Separate_Probe_SKU___SEN0208

The SN50v3-LB/LS detects the pulse width of the sensor and converts it to mm output. The accuracy will be within 1 centimeter. The usable range (the distance between the ultrasonic probe and the measured object) is between 24cm and 600cm.

The working principle of this sensor is similar to the HC-SR04 ultrasonic sensor.

The picture below shows the connection:

Connect to the SN50v3-LB/LS and run AT+MOD=2 to switch to ultrasonic mode (ULT).

The ultrasonic sensor uses the 8th and 9th byte for the measurement value.

Example:

Distance: Read: 0C2D(Hex) = 3117(D) Value: 3117 mm=311.7 cm

2.3.3.9 Battery Output - BAT pin

The BAT pin of SN50v3-LB/LS is connected to the Battery directly. If users want to use BAT pin to power an external sensor. User need to make sure the external sensor is of low power consumption. Because the BAT pin is always open. If the external sensor is of high power consumption. the battery of SN50v3-LB/LS will run out very soon.

2.3.3.10 +5V Output

SN50v3-LB/LS will enable +5V output before all sampling and disable the +5v after all sampling.

The 5V output time can be controlled by AT Command.

AT+5VT=1000

Means set 5V valid time to have 1000ms. So the real 5V output will actually have 1000ms + sampling time for other sensors.

By default the AT+5VT=500. If the external sensor which require 5v and require more time to get stable state, user can use this command to increase the power ON duration for this sensor.

2.3.3.11 BH1750 Illumination Sensor

MOD=1 support this sensor. The sensor value is in the 8th and 9th bytes.

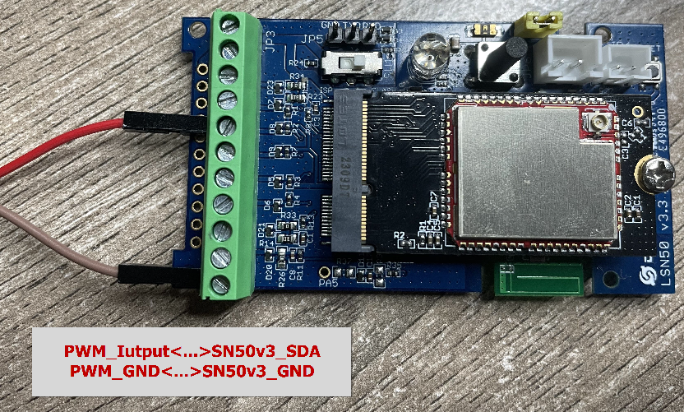

2.3.3.12 PWM MOD

The maximum voltage that the SDA pin of SN50v3 can withstand is 3.6V, and it cannot exceed this voltage value, otherwise the chip may be burned.

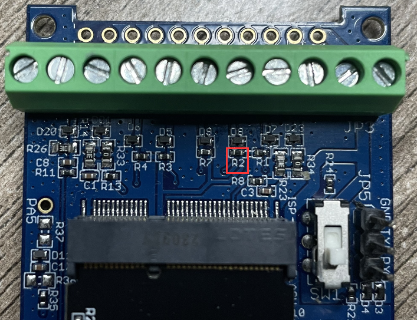

If the PWM pin connected to the SDA pin cannot maintain a high level when it is not working, you need to remove the resistor R2 or replace it with a resistor with a larger resistance, otherwise a sleep current of about 360uA will be generated. The position of the resistor is shown in the figure below:

The signal captured by the input should preferably be processed by hardware filtering and then connected in. The software processing method is to capture four values, discard the first captured value, and then take the middle value of the second, third, and fourth captured values.

Since the device can only detect a pulse period of 50ms when AT+PWMSET=0 (counting in microseconds), it is necessary to change the value of PWMSET according to the frequency of input capture.

PWM Input allows low power consumption. PWM Output to achieve real-time control, you need to go to class C. Power consumption will not be low.

For PWM Output Feature, there are two consideration to see if the device can be powered by battery or have to be powered by external DC.

a) If real-time control output is required, the SN50v3-LB/LS is already operating in class C and an external power supply must be used.

b) If the output duration is more than 30 seconds, better to use external power source.

2.3.3.13 Working MOD

The working MOD info is contained in the Digital in & Digital Interrupt byte (7th Byte).

User can use the 3rd ~ 7th bit of this byte to see the working mod:

Case 7th Byte >> 2 & 0x1f:

- 0: MOD1

- 1: MOD2

- 2: MOD3

- 3: MOD4

- 4: MOD5

- 5: MOD6

- 6: MOD7

- 7: MOD8

- 8: MOD9

- 9: MOD10

2.4 Payload Decoder file

In TTN, use can add a custom payload so it shows friendly reading

In the page Applications --> Payload Formats --> Custom --> decoder to add the decoder from:

https://github.com/dragino/dragino-end-node-decoder/tree/main/SN50_v3-LB

2.5 Frequency Plans

The SN50v3-LB/LS uses OTAA mode and below frequency plans by default. Each frequency band use different firmware, user update the firmware to the corresponding band for their country.

http://wiki.dragino.com/xwiki/bin/view/Main/End%20Device%20Frequency%20Band/

3. Configure SN50v3-LB/LS

3.1 Configure Methods

SN50v3-LB/LS supports below configure method:

- AT Command via Bluetooth Connection (Recommended): BLE Configure Instruction.

- AT Command via UART Connection : See UART Connection.

- LoRaWAN Downlink. Instruction for different platforms: See IoT LoRaWAN Server section.

3.2 General Commands

These commands are to configure:

- General system settings like: uplink interval.

- LoRaWAN protocol & radio related command.

They are same for all Dragino Devices which support DLWS-005 LoRaWAN Stack. These commands can be found on the wiki:

http://wiki.dragino.com/xwiki/bin/view/Main/End%20Device%20AT%20Commands%20and%20Downlink%20Command/

3.3 Commands special design for SN50v3-LB/LS

These commands only valid for SN50v3-LB/LS, as below:

3.3.1 Set Transmit Interval Time

Feature: Change LoRaWAN End Node Transmit Interval.

AT Command: AT+TDC

| Command Example | Function | Response |

|---|---|---|

| AT+TDC=? | Show current transmit Interval | 30000 |

| AT+TDC=60000 | Set Transmit Interval | OK |

Downlink Command: 0x01

Format: Command Code (0x01) followed by 3 bytes time value.

If the downlink payload=0100003C, it means set the END Node's Transmit Interval to 0x00003C=60(S), while type code is 01.

- Example 1: Downlink Payload: 0100001E // Set Transmit Interval (TDC) = 30 seconds

- Example 2: Downlink Payload: 0100003C // Set Transmit Interval (TDC) = 60 seconds

3.3.2 Get Device Status

Send a LoRaWAN downlink to ask the device to send its status.

Downlink Payload: 0x26 01

Sensor will upload Device Status via FPORT=5. See payload section for detail.

3.3.3 Set Interrupt Mode

3.3.3.1 Before V1.3.4 firmware

Note: Before V1.3.4 firmware, the interrupt function of PA8,PA4,PB15 had only one parameter to set, which was used to set the interrupt trigger mode.

Feature, Set Interrupt mode for PA8, PA4, PB15.

Before using the interrupt function of the INT pin, users can set the interrupt triggering mode as required.

AT Command: AT+INTMODx=a

AT+INTMODx:

- AT+INTMOD1 // Set the interrupt mode for PA8 pin.

- AT+INTMOD2 // Set the interrupt mode for PA4 pin.

- AT+INTMOD3 // Set the interrupt mode for PB15 pin.

Parameter a setting:

- 0: Disable Interrupt

- 1: Trigger by rising and falling edge

- 2: Trigger by falling edge

- 3: Trigger by rising edge

Example:

- AT+INTMOD1=0 //Disable the PA8 pin interrupt function

- AT+INTMOD2=2 //Set the interrupt of the PA4 pin to be triggered by the falling edge

- AT+INTMOD3=3 //Set the interrupt of the PB15 pin to be triggered by the rising edge

Downlink Command: 0x06 00 aa bb

Format: Command Code (0x06 00) followed by 2 bytes.

aa: Set the corresponding pin. (00: PA8 Pin; 01: PA4 Pin; 02: PB15 Pin.)

bb: Set interrupt mode. (00 Disable, 01 falling or rising, 02 falling, 03 rising)

Example:

- Downlink Payload: 06 00 00 01 // Equal to AT+INTMOD1=1

- Downlink Payload: 06 00 01 02 // Equal to AT+INTMOD2=2

- Downlink Payload: 06 00 02 03 // Equal to AT+INTMOD3=3

3.3.3.2 Since V1.3.4 firmware

Note: Since V1.3.4 firmware, the Interrupt function has added a new parameter to set the delay time, i.e. the state hold time.

AT Command: AT+INTMODx=a,b

| Parameter | Values and functions |

|---|---|

x | 1: Set the interrupt mode for PA8 pin. 2: Set the interrupt mode for PA4 pin. 3: Set the interrupt mode for PB15 pin. |

a | 0: Disable Interrupt 1: Trigger by rising and falling edge 2: Trigger by falling edge 3: Trigger by rising edge |

| b | Set the delay time. (Default: 0) Value range: 0~65535 ms |

Example:

- AT+INTMOD1=0,0 // Disable the PA8 pin interrupt function

- AT+INTMOD2=2,1000 // Set the interrupt of the PA4 pin to be triggered by the falling edge, however, the interrupt will only be triggered if the low level state remains 1000ms

- AT+INTMOD3=3,2500 // Set the interrupt of the PB15 pin to be triggered by the rising edge, however, the interrupt will only be triggered if the high level state remains 2500ms

Downlink Command: 0x06 00 aa bb cc

Format: Command Code (0x06 00) followed by 4 bytes.

aa: 1 byte, set the corresponding pin. (00: PA8 Pin; 01: PA4 Pin; 02: PB15 Pin.)

bb: 1 byte, set interrupt mode. (00 Disable, 01 falling or rising, 02 falling, 03 rising)

cc: 2 bytes, Set the delay time. (0x00~0xFFFF)

Example:

- Downlink Payload: 06 00 00 01 00 00 // Equal to AT+INTMOD1=1,0

- Downlink Payload: 06 00 01 02 0B B8 // Equal to AT+INTMOD2=2,3000

- Downlink Payload: 06 00 02 03 03 E8 // Equal to AT+INTMOD3=3,1000

3.3.4 Set Power Output Duration

Control the output duration 5V . Before each sampling, device will

1. first enable the power output to external sensor,

2. keep it on as per duration, read sensor value and construct uplink payload

3. final, close the power output.

AT Command: AT+5VT

| Command Example | Function | Response |

|---|---|---|

| AT+5VT=? | Show 5V open time. | 500(default) |

| AT+5VT=1000 | Close after a delay of 1000 milliseconds. | OK |

Downlink Command: 0x07

Format: Command Code (0x07) followed by 2 bytes.

The first and second bytes are the time to turn on.

- Example 1: Downlink Payload: 070000 ---> AT+5VT=0

- Example 2: Downlink Payload: 0701F4 ---> AT+5VT=500

3.3.5 Set Weighing parameters

Feature: Working mode 5 is effective, weight initialization and weight factor setting of HX711.

AT Command: AT+WEIGRE,AT+WEIGAP

| Command Example | Function | Response |

|---|---|---|

| AT+WEIGRE | Weight is initialized to 0. | OK |

| AT+WEIGAP=? | 400.0 | OK(default) |

| AT+WEIGAP=400.3 | Set the factor to 400.3. | OK |

Downlink Command: 0x08

Format: Command Code (0x08) followed by 2 bytes or 4 bytes.

Use AT+WEIGRE when the first byte is 1, only 1 byte. When it is 2, use AT+WEIGAP, there are 3 bytes.

The second and third bytes are multiplied by 10 times to be the AT+WEIGAP value.

- Example 1: Downlink Payload: 0801 ---> AT+WEIGRE

- Example 2: Downlink Payload: 08020FA3 ---> AT+WEIGAP=400.3

- Example 3: Downlink Payload: 08020FA0 ---> AT+WEIGAP=400.0

3.3.6 Set Digital pulse count value

Feature: Set the pulse count value.

Count 1 is PA8 pin of mode 6 and mode 9. Count 2 is PA4 pin of mode 9.

AT Command: AT+SETCNT

| Command Example | Function | Response |

|---|---|---|

| AT+SETCNT=1,100 | Initialize the count value 1 to 100. | OK |

| AT+SETCNT=2,0 | Initialize the count value 2 to 0. | OK |

Downlink Command: 0x09

Format: Command Code (0x09) followed by 5 bytes.

The first byte is to select which count value to initialize, and the next four bytes are the count value to be initialized.

- Example 1: Downlink Payload: 090100000000 ---> AT+SETCNT=1,0

- Example 2: Downlink Payload: 0902000003E8 ---> AT+SETCNT=2,1000

3.3.7 Set Workmode

Feature: Switch working mode.

AT Command: AT+MOD

| Command Example | Function | Response |

|---|---|---|

| AT+MOD=? | Get the current working mode. | OK |

| AT+MOD=4 | Set the working mode to 3DS18B20s. | OK |

Downlink Command: 0x0A

Format: Command Code (0x0A) followed by 1 bytes.

- Example 1: Downlink Payload: 0A01 ---> AT+MOD=1

- Example 2: Downlink Payload: 0A04 ---> AT+MOD=4

3.3.8 PWM setting

Feature: Set the time acquisition unit for PWM input capture.

AT Command: AT+PWMSET

| Command Example | Function | Response |

|---|---|---|

| AT+PWMSET=? | 0 | 0(default) |

| AT+PWMSET=0 | The unit of PWM capture time is microsecond. The capture frequency range is between 20HZ and 100000HZ. | OK |

| AT+PWMSET=1 | The unit of PWM capture time is millisecond. The capture frequency range is between 5HZ and 250HZ. | OK |

Downlink Command: 0x0C

Format: Command Code (0x0C) followed by 1 bytes.

- Example 1: Downlink Payload: 0C00 ---> AT+PWMSET=0

- Example 2: Downlink Payload: 0C01 ---> AT+PWMSET=1

Feature: Set PWM output time, output frequency and output duty cycle.

AT Command: AT+PWMOUT

| Command Example | Function | Response |

|---|---|---|

| AT+PWMOUT=? | 0 | 0,0,0(default) |

| AT+PWMOUT=0,0,0 | The default is PWM input detection | OK |

| AT+PWMOUT=5,1000,50 | The PWM output time is 5ms, the output frequency is 1000HZ, and the output duty cycle is 50%.

| OK |

| Command Example | Function | parameters |

|---|---|---|

AT+PWMOUT=a,b,c

| Set PWM output time, output frequency and output duty cycle.

| a: Output time (unit: seconds) |

b: Output frequency (unit: HZ) range 5~100000HZ | ||

c: Output duty cycle (unit: %) |

Downlink Command: 0x0B

Format: Command Code (0x0B) followed by 6 bytes.

0B + Output frequency (3bytes)+ Output duty cycle (1bytes)+Output time (2bytes)

Downlink payload:0B bb cc aa ---> AT+PWMOUT=a,b,c

- Example 1: Downlink Payload: 0B 0003E8 32 0005 ---> AT+PWMOUT=5,1000,50

- Example 2: Downlink Payload: 0B 0007D0 3C 000A ---> AT+PWMOUT=10,2000,60

4. Battery & Power Cons

SN50v3-LB use ER26500 + SPC1520 battery pack and SN50v3-LS use 3000mAh Recharable Battery with Solar Panel. See below link for detail information about the battery info and how to replace.

Battery Info & Power Consumption Analyze .

5. OTA Firmware update

User can change firmware SN50v3-LB/LS to:

- Change Frequency band/ region.

- Update with new features.

- Fix bugs.

Firmware and changelog can be downloaded from : Firmware download link

Methods to Update Firmware:

- (Recommanded way) OTA firmware update via wireless: http://wiki.dragino.com/xwiki/bin/view/Main/Firmware%20OTA%20Update%20for%20Sensors/

- Update through UART TTL interface: Instruction.

6. Developer Guide

SN50v3 is an open source project, developer can use compile their firmware for customized applications. User can get the source code from:

Software Source Code: Releases · dragino/SN50v3 (github.com)

Hardware Design files: Hardware Source Files.

Compile instruction:Compile instruction

1. If you want to change frequency, modify the Preprocessor Symbols.

For example, change EU868 to US915

2. Compile and build

7. FAQ

7.1 How to generate PWM Output in SN50v3-LB/LS?

See this document: Generate PWM Output on SN50v3.

7.2 How to put several sensors to a SN50v3-LB/LS?

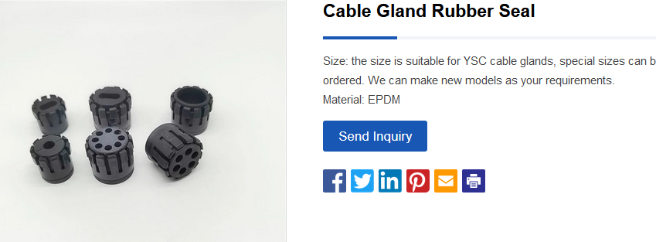

When we want to put several sensors to A SN50v3-LB/LS, the waterproof at the grand connector will become an issue. User can try to exchange the grand connector to below type.

8. Order Info

Part Number: SN50v3-LB-XX-YY or SN50v3-LS-XX-YY

XX: The default frequency band

- AS923: LoRaWAN AS923 band

- AS923-4: LoRaWAN AS923-4 band

- AU915: LoRaWAN AU915 band

- EU433: LoRaWAN EU433 band

- EU868: LoRaWAN EU868 band

- KR920: LoRaWAN KR920 band

- US915: LoRaWAN US915 band

- IN865: LoRaWAN IN865 band

- CN470: LoRaWAN CN470 band

YY: Hole Option

- 12: With M12 waterproof cable hole

- 16: With M16 waterproof cable hole

- 20: With M20 waterproof cable hole

- NH: No Hole

9. Packing Info

Package Includes:

- SN50v3-LB or SN50v3-LS LoRaWAN Generic Node

Dimension and weight:

Package Size / pcs :

- For SN50v3-LB: 140*80*50 mm

- For SN50v3-LS: 160*105*45 mm

Weight / pcs :

- For SN50v3-LB: 225 g

- For SN50v3-LS: 290 g

10. Support

- Support is provided Monday to Friday, from 09:00 to 18:00 GMT+8. Due to different timezones we cannot offer live support. However, your questions will be answered as soon as possible in the before-mentioned schedule.

- Provide as much information as possible regarding your enquiry (product models, accurately describe your problem and steps to replicate it etc) and send a mail to support@dragino.cc