PS-LB/LS -- LoRaWAN Air Water Pressure Sensor User Manual

Table of Contents :

- 1. Introduction

- 2. Configure PS-LB/LS to connect to LoRaWAN network

- 3. Configure PS-LB/LS

- 4. Battery & Power Consumption

- 5. OTA firmware update

- 6. FAQ

- 7. Troubleshooting

- 8. Order Info

- 9. Packing Info

- 10. Support

1. Introduction

1.1 What is LoRaWAN Pressure Sensor

The Dragino PS-LB/LS series sensors are LoRaWAN Pressure Sensor for Internet of Things solution. PS-LB/LS can measure Air, Water pressure and liquid level and upload the sensor data via wireless to LoRaWAN IoT server.

The PS-LB/LS series sensors include Thread Installation Type and Immersion Type, it supports different pressure range which can be used for different measurement requirement.

The LoRa wireless technology used in PS-LB/LS allows device to send data and reach extremely long ranges at low data-rates. It provides ultra-long range spread spectrum communication and high interference immunity whilst minimizing current consumption.

PS-LB/LS supports BLE configure and wireless OTA update which make user easy to use.

PS-LB/LS is powered by 8500mAh Li-SOCI2 battery or solar powered + Li-ion battery , it is designed for long term use up to 5 years.

Each PS-LB/LS is pre-load with a set of unique keys for LoRaWAN registrations, register these keys to local LoRaWAN server and it will auto connect after power on.

1.2 Features

- LoRaWAN 1.0.3 Class A

- Ultra-low power consumption

- Measure air / gas or water pressure

- Different pressure range available

- Thread Installation Type or Immersion Type

- Monitor Battery Level

- Bands: CN470/EU433/KR920/US915/EU868/AS923/AU915/IN865

- Support Bluetooth v5.1 and LoRaWAN remote configure

- Support wireless OTA update firmware

- Uplink on periodically

- Downlink to change configure

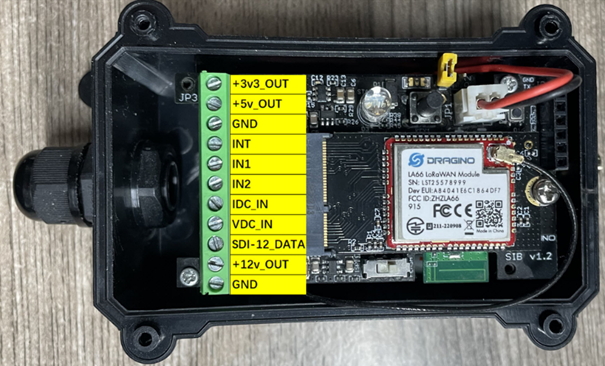

- Controllable 3.3v,5v and 12v output to power external sensor

- 8500mAh Li/SOCl2 Battery (PS-LB)

- Solar panel + 3000mAh Li-ion battery (PS-LS)

1.3 Specification

Micro Controller:

- MCU: 48Mhz ARM

- Flash: 256KB

- RAM: 64KB

Common DC Characteristics:

- Supply Voltage: Built-in Battery , 2.5v ~ 3.6v

- Operating Temperature: -40 ~ 85°C

LoRa Spec:

- Frequency Range, Band 1 (HF): 862 ~ 1020 Mhz,Band 2 (LF): 410 ~ 528 Mhz

- Max +22 dBm constant RF output vs.

- RX sensitivity: down to -139 dBm.

- Excellent blocking immunity

Current Input Measuring :

- Range: 0 ~ 20mA

- Accuracy: 0.02mA

- Resolution: 0.001mA

Voltage Input Measuring:

- Range: 0 ~ 30v

- Accuracy: 0.02v

- Resolution: 0.001v

Battery:

- Li/SOCI2 un-chargeable battery

- Capacity: 8500mAh

- Self-Discharge: <1% / Year @ 25°C

- Max continuously current: 130mA

- Max boost current: 2A, 1 second

Power Consumption

- Sleep Mode: 5uA @ 3.3v

- LoRa Transmit Mode: 125mA @ 20dBm, 82mA @ 14dBm

1.4 Probe Types

1.4.1 Thread Installation Type

- Hersman Pressure Transmitter

- Measuring Range: -0.1 ~ 0 ~ 60MPa, see order info.

- Accuracy: 0.2% F.S

- Long-Term Stability: 0.2% F.S ±0.05%

- Overload 200% F.S

- Zero Temperature Drift: 0.03% FS/℃(≤100Kpa), 0.02%FS/℃(>100Kpa)

- FS Temperature Drift: 0.003% FS/℃(≤100Kpa), 0.002%FS/℃(>100Kpa)

- Storage temperature: -30℃~80℃

- Operating temperature: -20℃~60℃

- Connector Type: Various Types, see order info

1.4.2 Immersion Type

- Immersion Type, Probe IP Level: IP68

- Measuring Range: Measure range can be customized, up to 100m.

- Accuracy: 0.2% F.S

- Long-Term Stability: ±0.2% F.S / Year

- Storage temperature: -30°C~80°C

- Operating temperature: 0°C~50°C

- Probe Material: 316 stainless steels

- Cable model specifications: CGYPU 5*0.2mm2

- Usage characteristics of Cable

1) Operating temperature:-40℃— +70℃

2) -30℃ bending cable 15 times of outer diameter can work normally

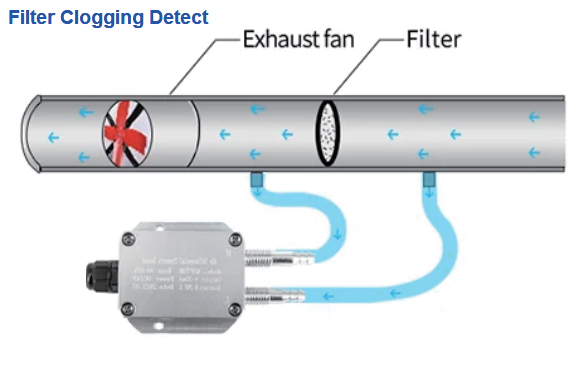

1.4.3 Wireless Differential Air Pressure Sensor

- Measuring Range: -100KPa~0~100KPa(Optional measuring range).

- Accuracy: 0.5% F.S, resolution is 0.05%.

- Overload: 300% F.S

- Zero temperature drift: ±0.03%F.S/°C

- Operating temperature: -20°C~60°C

- Storage temperature: -20°C~60°C

- Compensation temperature: 0~50°C

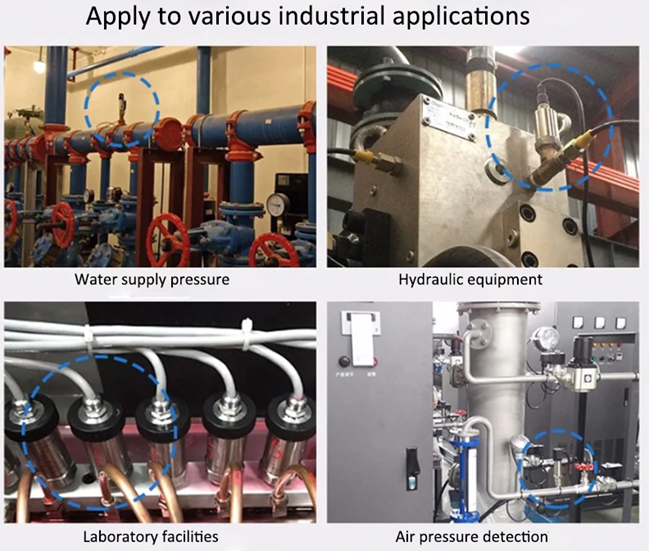

1.5 Application and Installation

1.5.1 Thread Installation Type

Application:

- Hydraulic Pressure

- Petrochemical Industry

- Health and Medical

- Food & Beverage Processing

- Auto-controlling house

- Constant Pressure Water Supply

- Liquid Pressure measuring

Order the suitable thread size and install to measure the air / liquid pressure

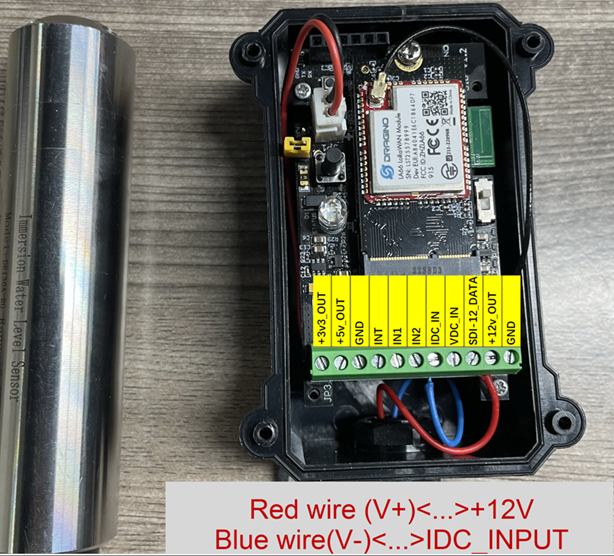

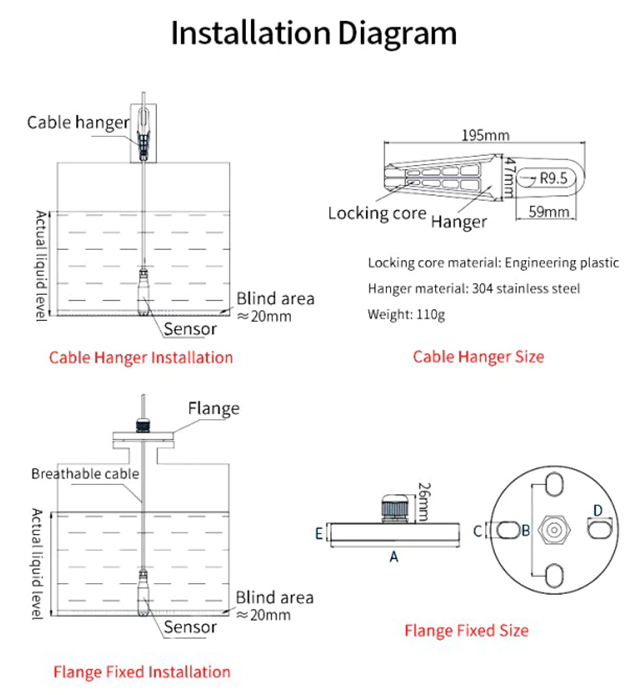

1.5.2 Immersion Type

Application:

Liquid & Water Pressure / Level detect.

Below is the wiring to for connect the probe to the device.

The Immersion Type Sensor has different variant which defined by Ixx. For example, this means two points:

- Cable Length: 10 Meters

- Water Detect Range: 0 ~ 10 Meters.

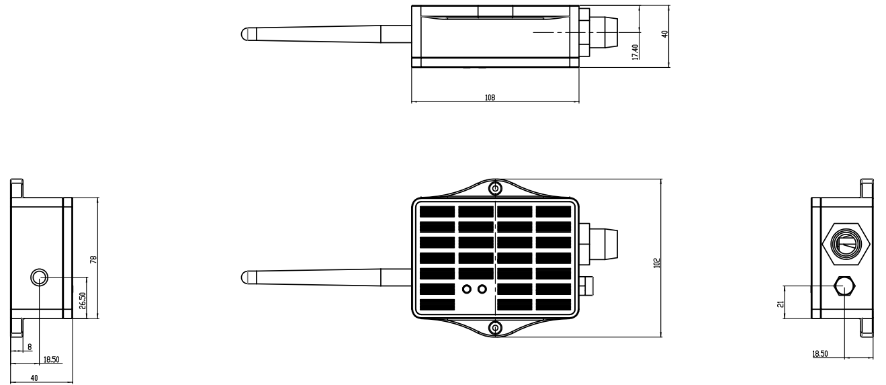

Size of immersion type water depth sensor:

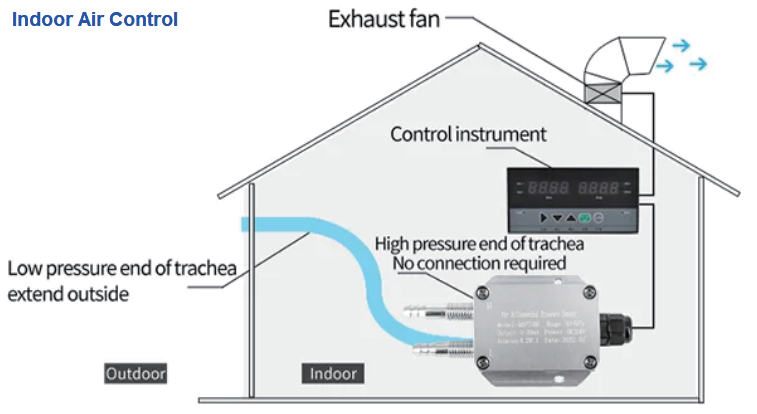

1.5.3 Wireless Differential Air Pressure Sensor

Application:

Indoor Air Control & Filter clogging Detect.

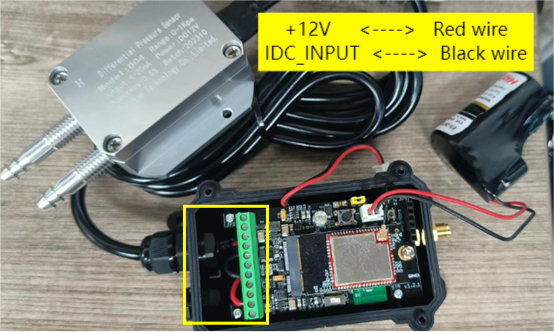

Below is the wiring to for connect the probe to the device.

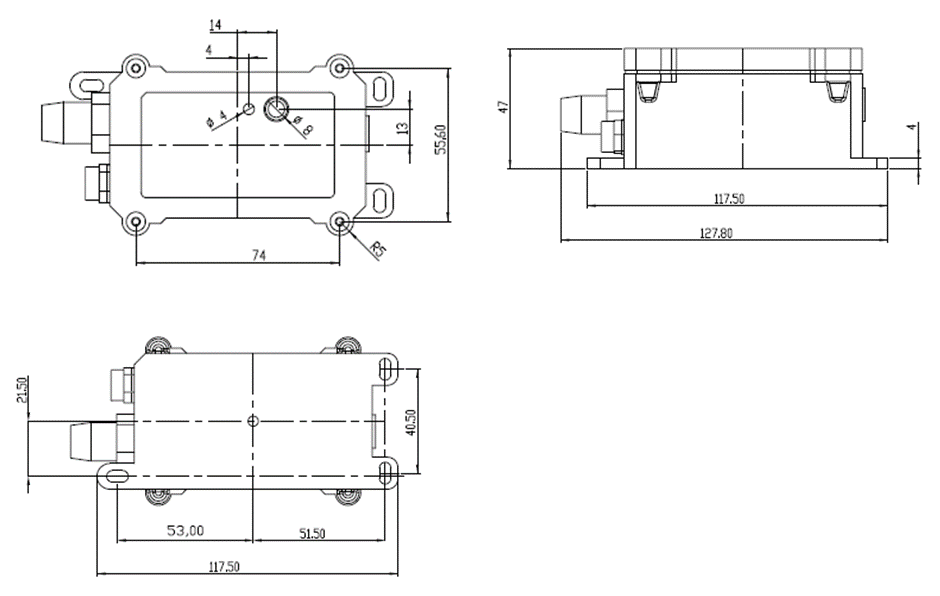

Size of wind pressure transmitter:

Note: The above dimensions are measured by hand, and the numerical error of the shell is within ±0.2mm.

1.6 Sleep mode and working mode

Deep Sleep Mode: Sensor doesn't have any LoRaWAN activate. This mode is used for storage and shipping to save battery life.

Working Mode: In this mode, Sensor will work as LoRaWAN Sensor to Join LoRaWAN network and send out sensor data to server. Between each sampling/tx/rx periodically, sensor will be in IDLE mode), in IDLE mode, sensor has the same power consumption as Deep Sleep mode.

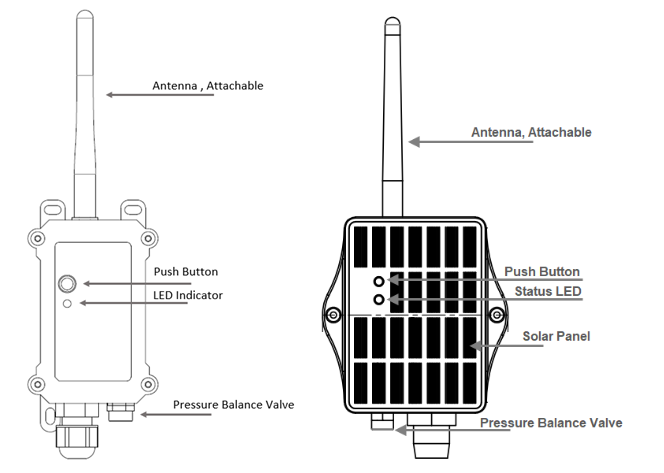

1.7 Button & LEDs

| Behavior on ACT | Function | Action |

|---|---|---|

1~3s 1~3s | Send an uplink | If sensor is already Joined to LoRaWAN network, sensor will send an uplink packet, blue led will blink once. |

>3s >3s | Active Device | Green led will fast blink 5 times, device will enter OTA mode for 3 seconds. And then start to JOIN LoRaWAN network. |

x5 x5 | Deactivate Device | Red led will solid on for 5 seconds. Means PS-LB is in Deep Sleep Mode. |

1.8 Pin Mapping

1.9 BLE connection

PS-LB/LS support BLE remote configure.

BLE can be used to configure the parameter of sensor or see the console output from sensor. BLE will be only activate on below case:

- Press button to send an uplink

- Press button to active device.

- Device Power on or reset.

If there is no activity connection on BLE in 60 seconds, sensor will shut down BLE module to enter low power mode.

1.10 Mechanical

1.10.1 for LB version

1.10.2 for LS version

2. Configure PS-LB/LS to connect to LoRaWAN network

2.1 How it works

The PS-LB/LS is configured as LoRaWAN OTAA Class A mode by default. It has OTAA keys to join LoRaWAN network. To connect a local LoRaWAN network, you need to input the OTAA keys in the LoRaWAN IoT server and activate the PS-LB/LS. It will automatically join the network via OTAA and start to send the sensor value. The default uplink interval is 20 minutes.

2.2 Quick guide to connect to LoRaWAN server (OTAA)

Following is an example for how to join the TTN v3 LoRaWAN Network. Below is the network structure; we use the LPS8v2 as a LoRaWAN gateway in this example.

The LPS8V2 is already set to connected to TTN network , so what we need to now is configure the TTN server.

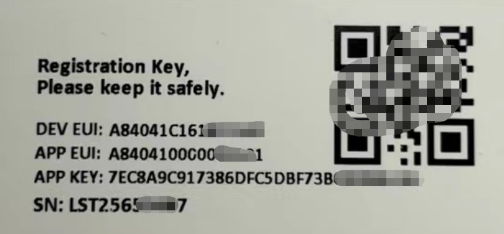

Step 1: Create a device in TTN with the OTAA keys from PS-LB/LS.

Each PS-LB/LS is shipped with a sticker with the default device EUI as below:

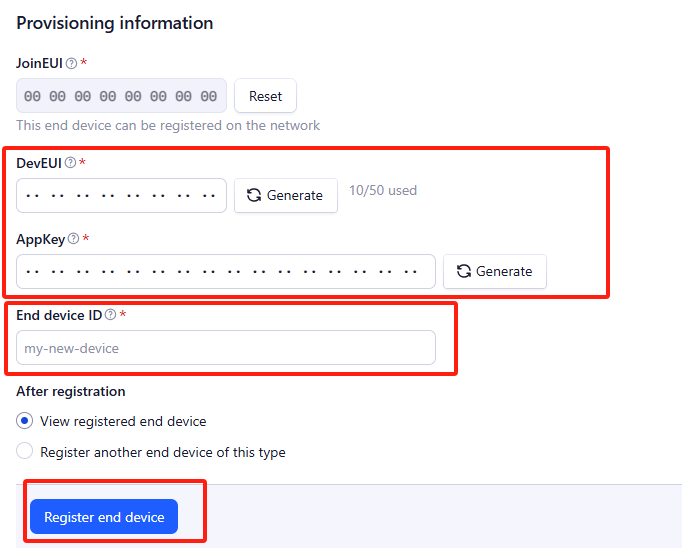

You can enter this key in the LoRaWAN Server portal. Below is TTN screen shot:

Create the application.

Add devices to the created Application.

Enter end device specifics manually.

Add DevEUI and AppKey. Customize a platform ID for the device.

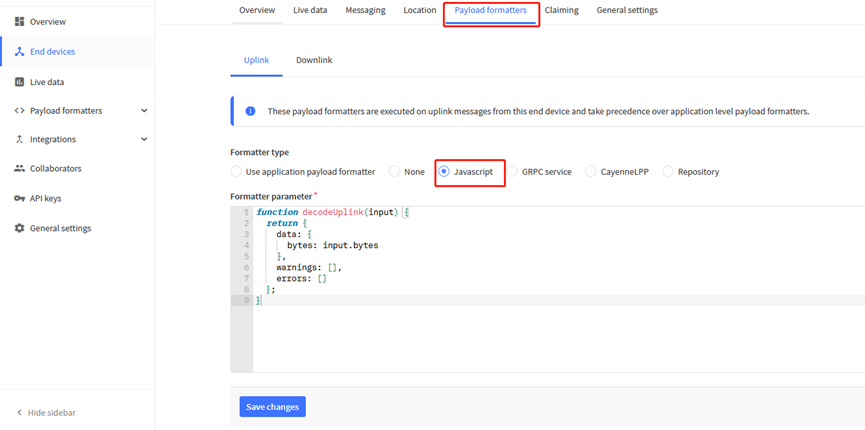

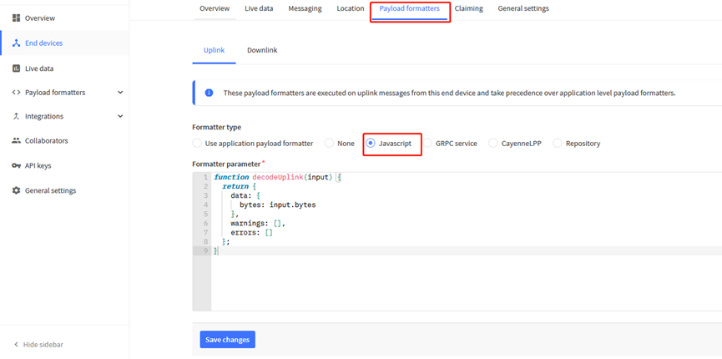

Step 2: Add decoder.

In TTN, user can add a custom payload so it shows friendly reading.

Click this link to get the decoder: https://github.com/dragino/dragino-end-node-decoder/tree/main/

Below is TTN screen shot:

Step 3: Activate on PS-LB/LS

Press the button for 5 seconds to activate the PS-LB/LS.

Green led will fast blink 5 times, device will enter OTA mode for 3 seconds. And then start to JOIN LoRaWAN network. Green led will solidly turn on for 5 seconds after joined in network.

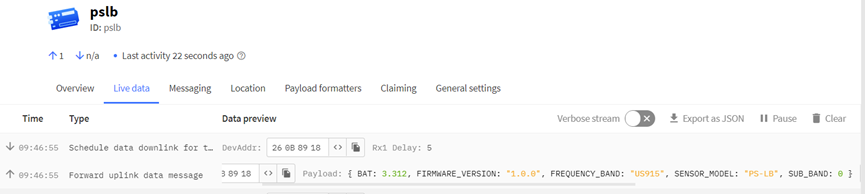

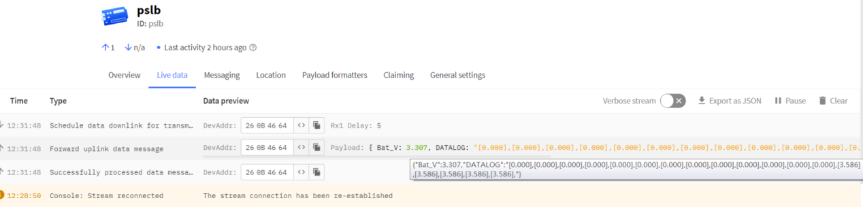

After join success, it will start to upload messages to TTN and you can see the messages in the panel.

2.3 Uplink Payload

2.3.1 Device Status, FPORT=5

Include device configure status. Once PS-LB/LS Joined the network, it will uplink this message to the server.

Users can also use the downlink command(0x26 01) to ask PS-LB/LS to resend this uplink.

| Device Status (FPORT=5) | |||||

| Size (bytes) | 1 | 2 | 1 | 1 | 2 |

| Value | Sensor Model | Firmware Version | Frequency Band | Sub-band | BAT |

Example parse in TTNv3

Sensor Model: For PS-LB/LS, this value is 0x16

Firmware Version: 0x0100, Means: v1.0.0 version

Frequency Band:

*0x01: EU868

*0x02: US915

*0x03: IN865

*0x04: AU915

*0x05: KZ865

*0x06: RU864

*0x07: AS923

*0x08: AS923-1

*0x09: AS923-2

*0x0a: AS923-3

*0x0b: CN470

*0x0c: EU433

*0x0d: KR920

*0x0e: MA869

Sub-Band:

AU915 and US915:value 0x00 ~ 0x08

CN470: value 0x0B ~ 0x0C

Other Bands: Always 0x00

Battery Info:

Check the battery voltage.

Ex1: 0x0B45 = 2885mV

Ex2: 0x0B49 = 2889mV

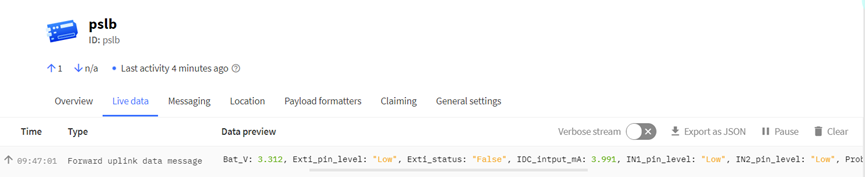

2.3.2 Sensor value, FPORT=2

Uplink payload includes in total 9 bytes.

Size(bytes) | 2 | 2 | 2 | 2 | 1 |

| Value | BAT | Probe Model | 0 ~ 20mA value | 0 ~ 30v value | IN1 &IN2 Interrupt flag |

2.3.3 Battery Info

Check the battery voltage for PS-LB/LS.

Ex1: 0x0B45 = 2885mV

Ex2: 0x0B49 = 2889mV

2.3.4 Probe Model

PS-LB/LS has different kind of probe, 4~20mA represent the full scale of the measuring range. So a 12mA output means different meaning for different probe.

For example.

| Part Number | Probe Used | 4~20mA scale | Example: 12mA meaning |

| PS-LB/LS-I3 | immersion type with 3 meters cable | 0~3 meters | 1.5 meters pure water |

| PS-LB/LS-I5 | immersion type with 5 meters cable | 0~5 meters | 2.5 meters pure water |

| PS-LB/LS-T20-B | T20 threaded probe | 0~1MPa | 0.5MPa air / gas or water pressure |

The probe model field provides the convenient for server to identical how it should parse the 4~20mA sensor value and get the correct value.

When connecting to current sensors sold by our company, you can convert current readings to corresponding values by simply configuring the AT+PROBE command. If you prefer not to configure this command on the sensor, you can uniformly handle the conversion in the payload decoder instead.

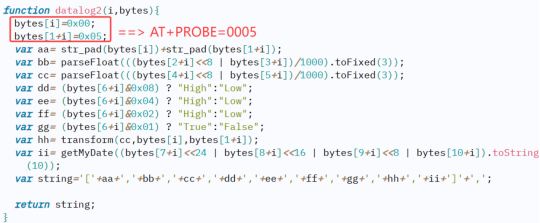

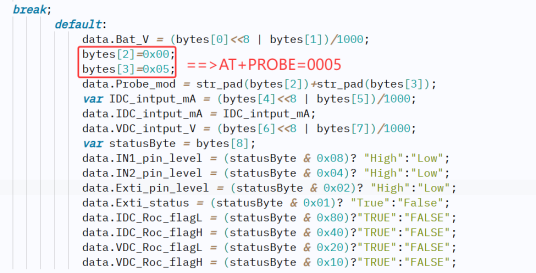

Examples for decoder implementation:

1. For AT+PROBE=0005, add the following processing in your decoder:

2. For AT+PROBE=0102, add the following processing in your decoder(Corresponding to the position shown in the above screenshot).

bytes[i]=0x01;bytes[1+i]=0x02;

bytes[2]=0x01;bytes[3]=0x02;

2.3.5 0~20mA value (IDC_IN)

The output value from Pressure Probe, use together with Probe Model to get the pressure value or water level.

Example:

27AE(H) = 10158 (D)/1000 = 10.158mA.

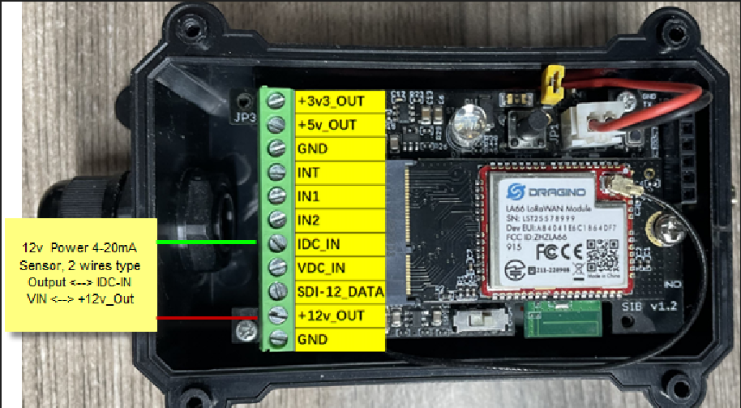

Instead of pressure probe, User can also connect a general 4~20mA in this port to support different types of 4~20mA sensors. below is the connection example:

2.3.6 0~30V value (pin VDC_IN)

Measure the voltage value. The range is 0 to 30V.

Example:

138E(H) = 5006(D)/1000= 5.006V

2.3.7 IN1&IN2&INT pin

IN1 and IN2 are used as digital input pins.

Example:

09 (H): (0x09&0x08)>>3=1 IN1 pin is high level.

09 (H): (0x09&0x04)>>2=0 IN2 pin is low level.

This data field shows if this packet is generated by Interrupt Pin or not. Click here for the hardware and software set up. Note: The Internet Pin is a separate pin in the screw terminal.

Example:

09 (H): (0x09&0x02)>>1=1 The level of the interrupt pin.

09 (H): 0x09&0x01=1 0x00: Normal uplink packet.

0x01: Interrupt Uplink Packet.

2.3.8 Sensor value, FPORT=7

Size(bytes) | 2 | n |

| Value | BAT | Voltage value, each 2 bytes is a set of voltage values. |

Multiple sets of data collected are displayed in this form:

[voltage value1], [voltage value2], [voltage value3],…[voltage value n/2]

2.3.9 Decode payload in The Things Network

While using TTN network, you can add the payload format to decode the payload.

PS-LB/LS TTN Payload Decoder: https://github.com/dragino/dragino-end-node-decoder

2.4 Uplink Interval

The PS-LB/LS by default uplink the sensor data every 20 minutes. User can change this interval by AT Command or LoRaWAN Downlink Command. See this link: http://wiki.dragino.com/xwiki/bin/view/Main/End%20Device%20AT%20Commands%20and%20Downlink%20Command/#H4.1ChangeUplinkInterval

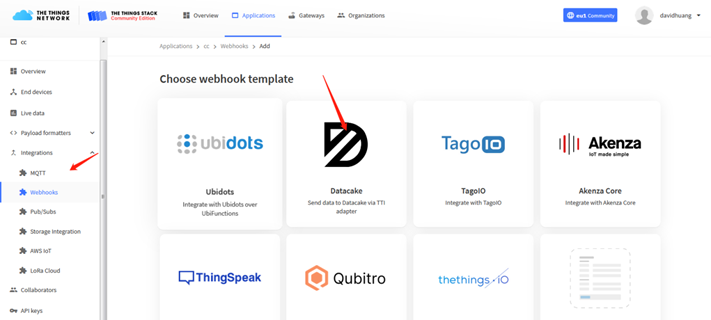

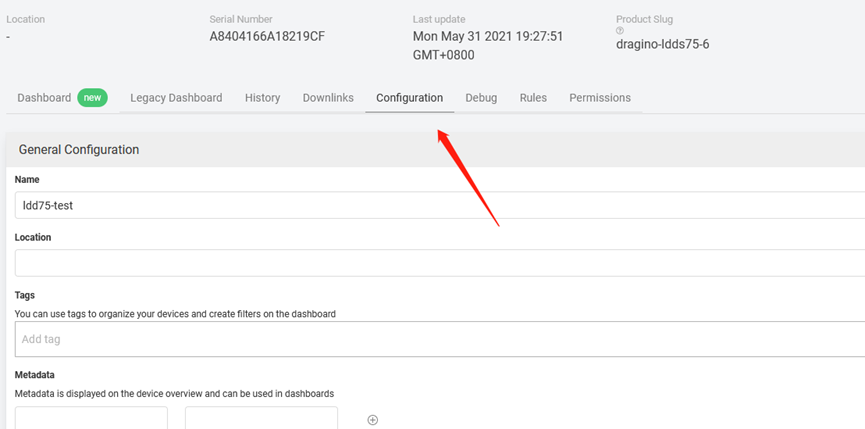

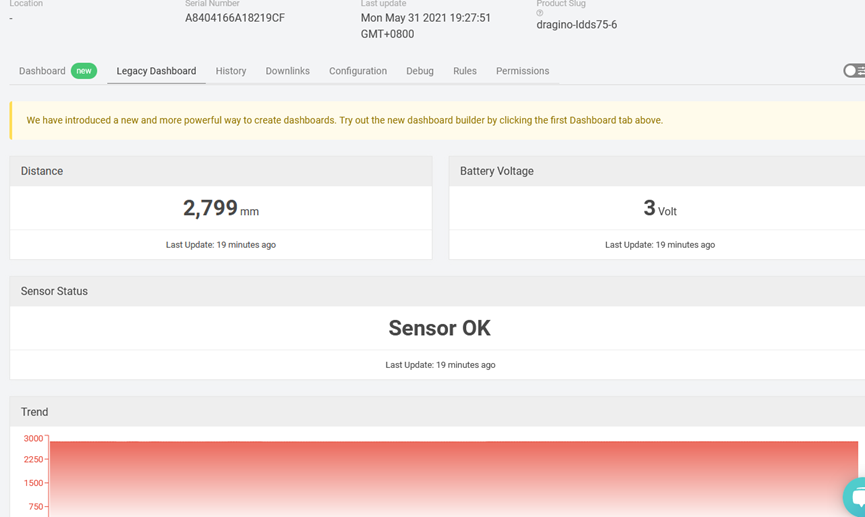

2.5 Show Data in DataCake IoT Server

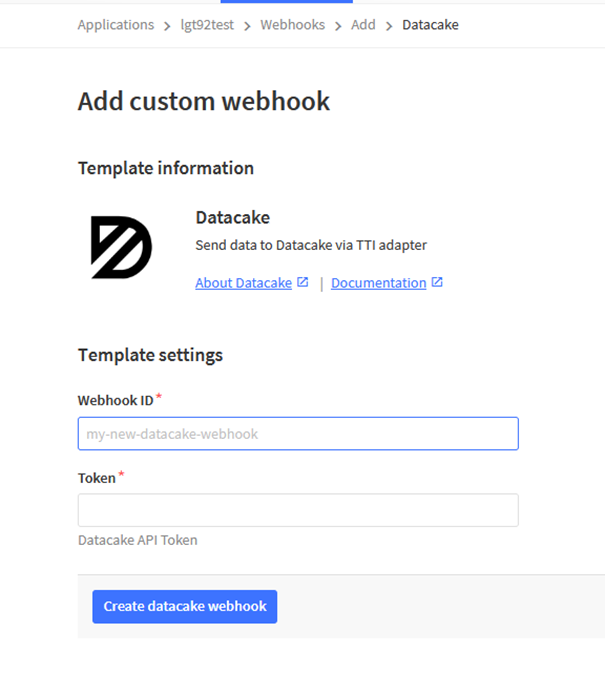

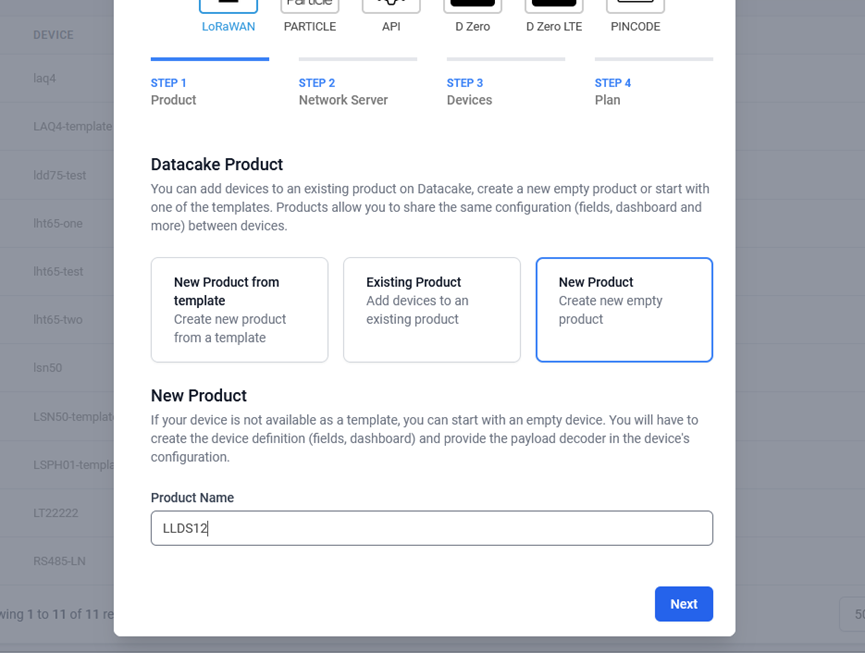

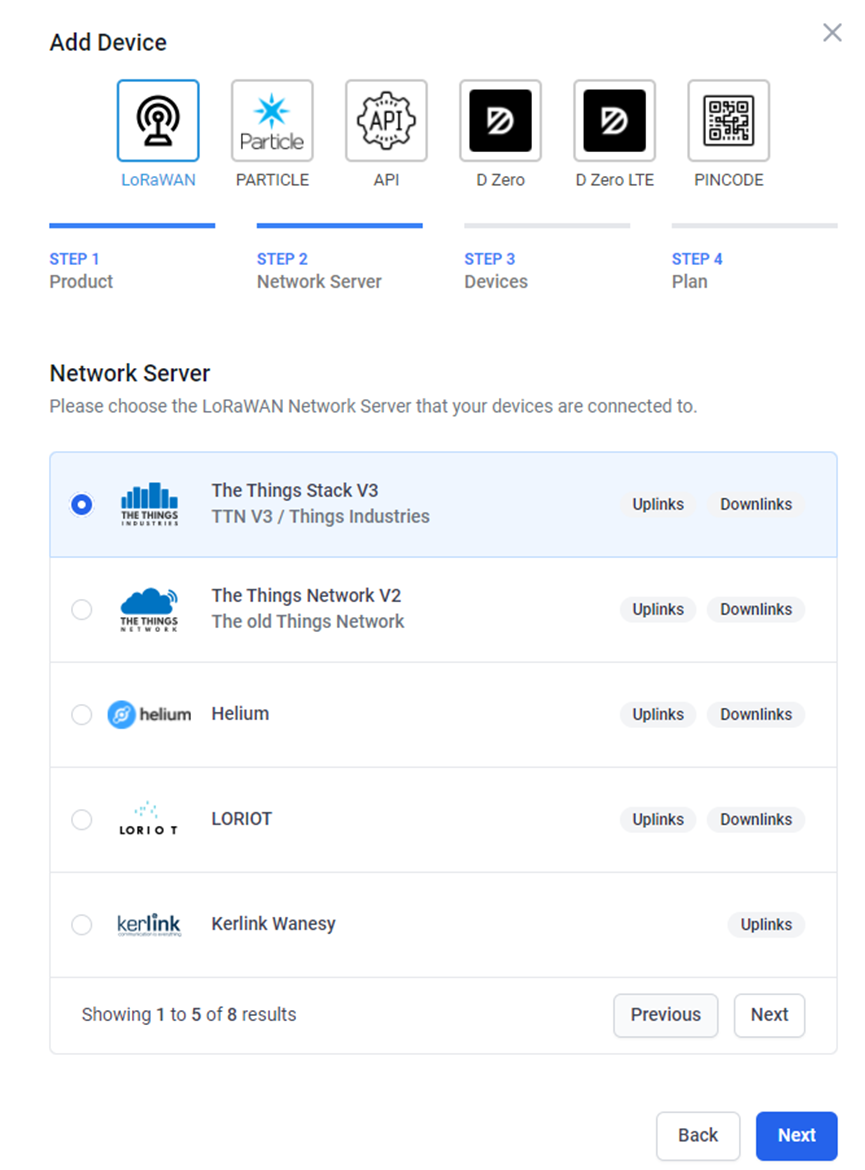

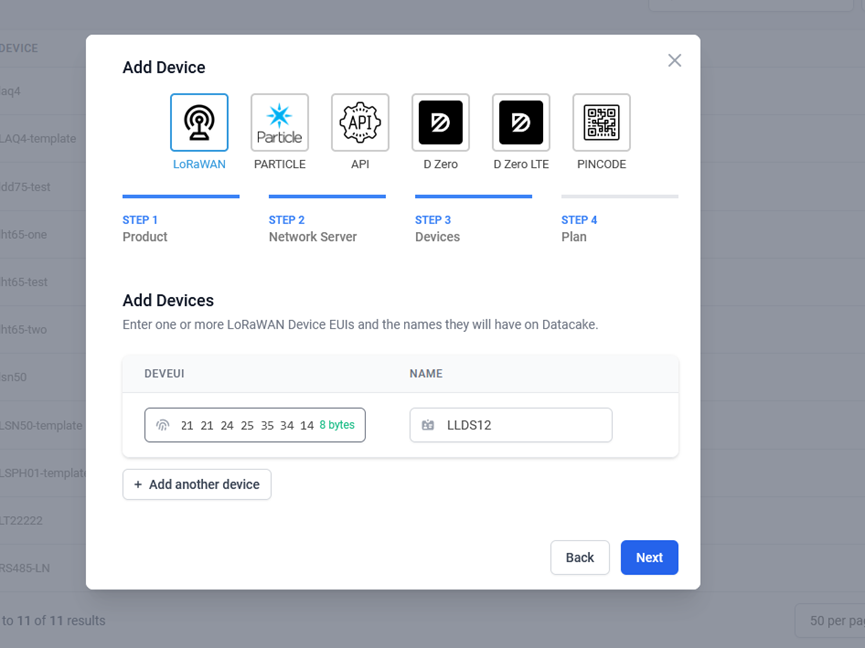

DATACAKE provides a human friendly interface to show the sensor data, once we have data in TTN, we can use DATACAKE to connect to TTN and see the data in DATACAKE. Below are the steps:

Step 1: Be sure that your device is programmed and properly connected to the network at this time.

Step 2: To configure the Application to forward data to DATACAKE you will need to add integration. To add the DATACAKE integration, perform the following steps:

Step 3: Create an account or log in Datacake.

Step 4: Create PS-LB/LS product.

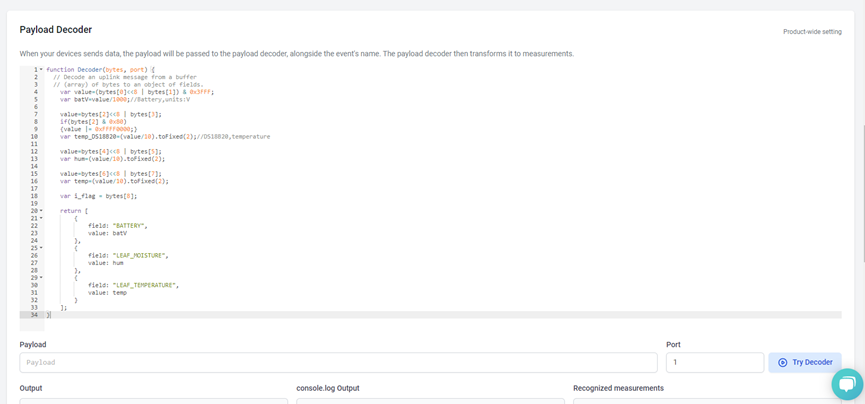

Step 5: add payload decode

After added, the sensor data arrive TTN, it will also arrive and show in Datacake.

2.6 Datalog Feature (Since V1.1)

Datalog Feature is to ensure IoT Server can get all sampling data from Sensor even if the LoRaWAN network is down. For each sampling, PS-LB will store the reading for future retrieving purposes.

2.6.1 How datalog works

PS-LB will wait for ACK for every uplink, when there is no LoRaWAN network,PS-LB will mark these records with non-ack messages and store the sensor data, and it will send all messages (10s interval) after the network recovery.

a) PS-LB will do an ACK check for data records sending to make sure every data arrive server.

b) PS-LB will send data in CONFIRMED Mode, but PS-LB won't re-transmit the packet if it doesn't get ACK, it will just mark it as a NONE-ACK message. In a future uplink if PS-LB gets a ACK, PS-LB will consider there is a network connection and resend all NONE-ACK messages.

2.6.2 Enable Datalog

User need to make sure below two settings are enable to use datalog;

- SYNCMOD=1(Default) to enable sync time via LoRaWAN MAC command, click here (AT+SYNCMOD) for detailed instructions.

- PNACKMD=1 to enable datalog feature, click here (AT+PNACKMD) for detailed instructions.

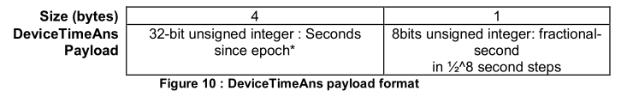

Once PS-LB Joined LoRaWAN network, it will send the MAC command (DeviceTimeReq) and the server will reply with (DeviceTimeAns) to send the current time to PS-LB. If PS-LB fails to get the time from the server, PS-LB will use the internal time and wait for next time request (AT+SYNCTDC to set the time request period, default is 10 days).

Note: LoRaWAN Server need to support LoRaWAN v1.0.3(MAC v1.0.3) or higher to support this MAC command feature, Chirpstack,TTN V3 v3 and loriot support but TTN V3 v2 doesn't support. If server doesn't support this command, it will through away uplink packet with this command, so user will lose the packet with time request for TTN V3 v2 if SYNCMOD=1.

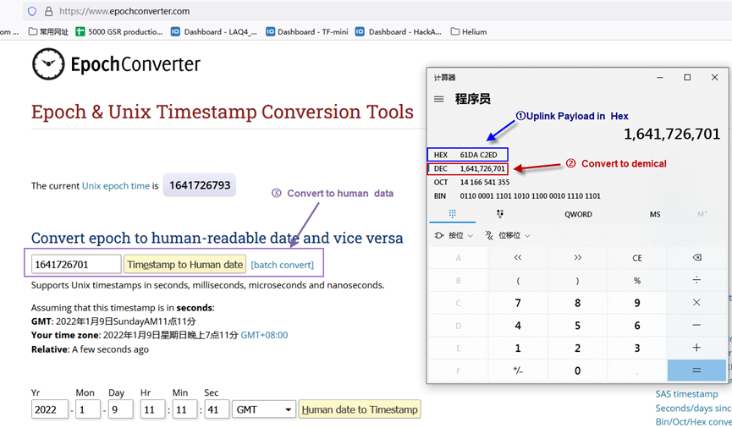

2.6.3 Unix TimeStamp

PS-LB uses Unix TimeStamp format based on

Users can get this time from the link: https://www.epochconverter.com/ :

Below is the converter example:

2.6.4 Poll sensor value

Users can poll sensor values based on timestamps. Below is the downlink command.

| Downlink Command to poll Open/Close status (0x31) | |||

|---|---|---|---|

| 1byte | 4bytes | 4bytes | 1byte |

| 31 | Timestamp start | Timestamp end | Uplink Interval |

Timestamp start and Timestamp end-use Unix TimeStamp format as mentioned above. Devices will reply with all data logs during this period, using the uplink interval.

For example, downlink command

Is to check 2024/12/20 09:34:59 to 2024/12/20 14:34:59's data

Uplink Internal =5s,means PS-LB will send one packet every 5s. range 5~255s.

2.6.5 Datalog Uplink payload (FPORT=3)

The Datalog uplinks will use below payload format.

Retrieval data payload:

Size(bytes) | 2 | 2 | 2 | 1 | 4 |

|---|---|---|---|---|---|

| Value | Probe_mod | VDC_intput_V | IDC_intput_mA | IN1_pin_level& IN2_pin_level& Exti_pin_level&Exti_status | Unix Time Stamp |

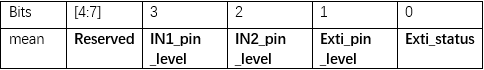

IN1_pin_level & IN2_pin_level & Exti_pin_level & Exti_status:

No ACK Message: 1: This message means this payload is fromn Uplink Message which doesn't get ACK from the server before ( for PNACKMD=1 feature)

Poll Message Flag: 1: This message is a poll message reply.

- Poll Message Flag is set to 1.

- Each data entry is 11 bytes, to save airtime and battery, devices will send max bytes according to the current DR and Frequency bands.

For example, in US915 band, the max payload for different DR is:

a) DR0: max is 11 bytes so one entry of data

b) DR1: max is 53 bytes so devices will upload 4 entries of data (total 44 bytes)

c) DR2: total payload includes 11 entries of data

d) DR3: total payload includes 22 entries of data.

If devise doesn't have any data in the polling time. Device will uplink 11 bytes of 0

Example:

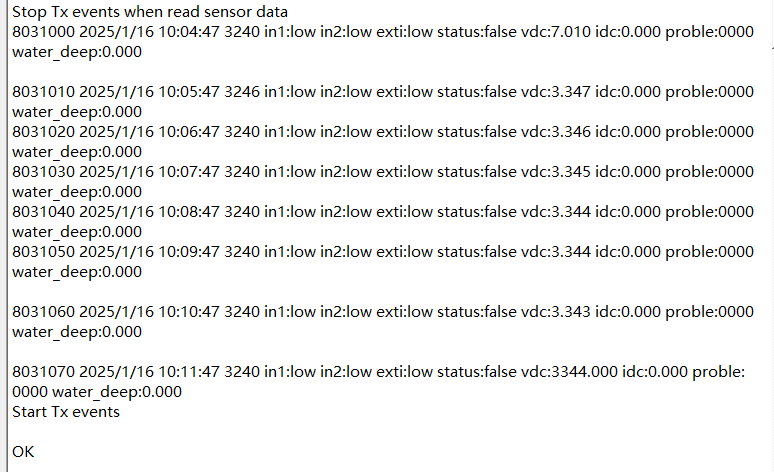

If PS-LB-NA has below data inside Flash:

If user sends below downlink command: 316788D9BF6788DB6305

Where : Start time: 6788D9BF = time 25/1/16 10:04:47

Stop time: 6788DB63 = time 25/1/16 10:11:47

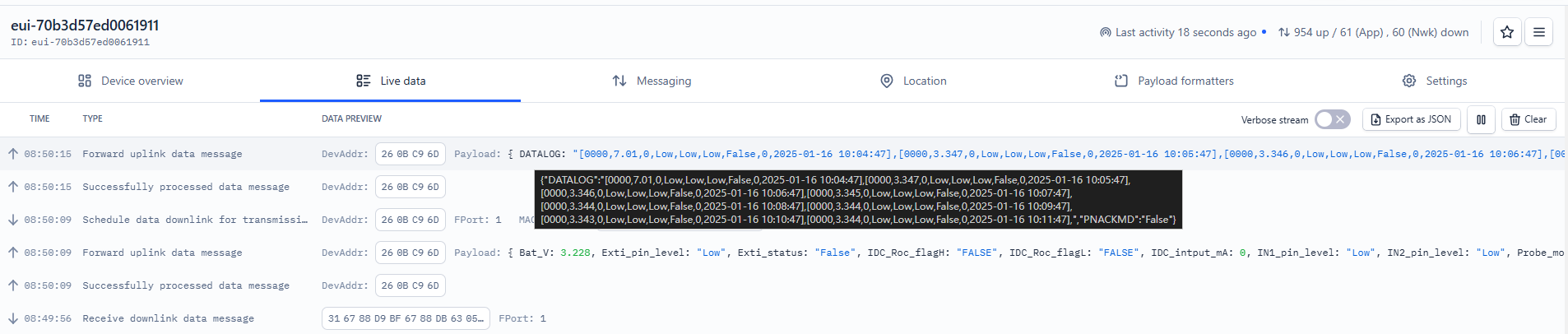

PA-LB-NA will uplink this payload.

00001B620000406788D9BF 00000D130000406788D9FB 00000D120000406788DA37 00000D110000406788DA73 00000D100000406788DAAF 00000D100000406788DAEB 00000D0F0000406788DB27 00000D100000406788DB63

Where the first 11 bytes is for the first entry :

0000 0D10 0000 40 6788DB63

Probe_mod = 0x0000 = 0000

VDC_intput_V = 0x0D10/1000=3.344V

IDC_intput_mA = 0x0000/1000=0mA

IN1_pin_level = (0x40& 0x08)? "High":"Low" = 0(Low)

IN2_pin_level = (0x40& 0x04)? "High":"Low" = 0(Low)

Exti_pin_level = (0x40& 0x02)? "High":"Low" = 0(Low)

Exti_status = (0x40& 0x01)? "True":"False" = 0(False)

Unix time is 0x6788DB63 = 1737022307s = 2025/1/16 10:11:47

Its data format is:

[Probe_mod, VDC_intput_V, IDC_intput_mA, IN1_pin_level, IN2_pin_level, Exti_pin_level, water_deep, Data_time],[Probe_mod, VDC_intput_V, IDC_intput_mA, IN1_pin_level, IN2_pin_level, Exti_pin_level, water_deep, Data_time],...

Note: water_deep in the data needs to be converted using decoding to get it.

2.6.6 Decoder in TTN V3

Please check the decoder from this link: https://github.com/dragino/dragino-end-node-decoder

2.7 Frequency Plans

The PS-LB/LS uses OTAA mode and below frequency plans by default. Each frequency band use different firmware, user update the firmware to the corresponding band for their country.

http://wiki.dragino.com/xwiki/bin/view/Main/End%20Device%20Frequency%20Band/a

2.8 Report on Change Feature (Since firmware V1.2)

2.8.1 Uplink payload(Enable ROC)

Used to Monitor the IDC and VDC increments, and send ROC uplink when the IDC or VDC changes exceed.

With ROC enabled, the payload is as follows:

Size(bytes) | 2 | 2 | 2 | 2 | 1 |

| Value | BAT | Probe Model | 0 ~ 20mA value | 0 ~ 30v value | IN1 &IN2 Interrupt flag & ROC_flag |

IN1 &IN2 , Interrupt flag , ROC_flag:

| Size(bit) | bit7 | bit6 | bit5 | bit4 | bit3 | bit2 | bit1 | bit0 |

| Value | IDC_Roc_flagL | IDC_Roc_flagH | VDC_Roc_flagL | VDC_Roc_flagH | IN1_pin_level | IN2_pin_level | Exti_pin_level | Exti_status |

- IDC_Roc_flagL

80 (H): (0x80&0x80)=80(H)=1000 0000(B) bit7=1, "TRUE", This uplink is triggered when the decrease in the IDC compared to the last ROC refresh exceeds the set threshold.

60 (H): (0x60&0x80)=0 bit7=0, "FALSE", This uplink is not triggered when the decrease in the IDC compared to the last ROC refresh exceeds the set threshold.

- IDC_Roc_flagH

60 (H): (0x60&0x40)=60(H)=01000 0000(B) bit6=1, "TRUE", This uplink is triggered when the increase in the value of the IDC compared to the last ROC refresh exceeds the set threshold.

80 (H): (0x80&0x40)=0 bit6=0, "FALSE", This uplink is not triggered when the increase in the value of the IDC compared to the last ROC refresh exceeds the set threshold.

- VDC_Roc_flagL

20 (H): (0x20&0x20)=20(H)=0010 0000(B) bit5=1, "TRUE", This uplink is triggered when the decrease in the VDC compared to the last ROC refresh exceeds the set threshold.

90 (H): (0x90&0x20)=0 bit5=0, "FALSE", This uplink is not triggered when the decrease in the VDC compared to the last ROC refresh exceeds the set threshold.

- VDC_Roc_flagH

90 (H): (0x90&0x10)=10(H)=0001 0000(B) bit4=1, "TRUE", This uplink is triggered when the increase in the value of the VDC compared to the last ROC refresh exceeds the set threshold.

20 (H): (0x20&0x10)=0 bit4=0, "FALSE", This uplink is not triggered when the increase in the value of the VDC compared to the last ROC refresh exceeds the set threshold.

- IN1_pin_level & IN2_pin_level

IN1 and IN2 are used as digital input pins.

80 (H): (0x80&0x08)=0 IN1 pin is low level.

80 (H): (0x09&0x04)=0 IN2 pin is low level.

- Exti_pin_level &Exti_status

This data field shows whether the packet is generated by an interrupt pin.

Note: The Internet pin of the old motherboard is a separate pin in the screw terminal, and the interrupt pin of the new motherboard(SIB V1.3) is the GPIO_EXTI pin.

Exti_pin_level: 80 (H): (0x80&0x02)=0 "low", The level of the interrupt pin.

Exti_status: 80 (H): (0x80&0x01)=0 "False", Normal uplink packet.

2.8.2 Set the Report on Change

Feature: Get or Set the Report on Change.

2.8.2.1 Wave alarm mode

Feature: By setting the detection period and a change value, the IDC/VDC variable is monitored whether it exceeds the set change value. If this change value is exceeded, the ROC uplink is sent and the comparison value is flushed.

- Change value: The amount by which the next detection value increases/decreases relative to the previous detection value.

- Comparison value: A parameter to compare with the latest ROC test.

AT Command: AT+ROC

| Command Example | Parameters | Response/Explanation |

|---|---|---|

| AT+ROC=? | Show current ROC setting | 0,0,0,0(default) |

AT+ROC=a,b,c,d | a: Enable or disable the ROC | 0: off |

| b: Set the detection interval | Range: 0~65535s | |

| c: Setting the IDC change value | Unit: uA | |

| d: Setting the VDC change value | Unit: mV |

Example:

- AT+ROC=0,0,0,0 // The ROC function is not used.

- AT+ROC=1,60,3000, 500 // Check value every 60 seconds. lf there is change in IDC (>3mA) or VDC (>500mV), sends an ROC uplink, and the comparison value is refreshed.

- AT+ROC=1,60,3000,0 // Check value every 60 seconds. lf there is change in IDC (>3mA), send an ROC uplink and the comparison value of IDC is refreshed. dd=0 Means doesn't monitor Voltage.

- AT+ROC=2,60,3000,0 // Check value every 60 seconds. lf there is change in IDC (>3mA), send an ROC uplink and the comparison value of IDC is refreshed. dd=0 Means doesn't monitor Voltage. In addition, if the change in the IDC does not exceed 3mA, then the ROC uplink is not sent, and the comparison value is not refreshed by the ROC uplink packet. However, if the device TDC time arrives, or if the user manually sends packets, then the IDC comparison value is also refreshed.

Downlink Command: 0x09 aa bb cc dd

Format: Function code (0x09) followed by 4 bytes.

aa: 1 byte; Set the wave alarm mode.

bb: 2 bytes; Set the detection interval. (second)

cc: 2 bytes; Setting the IDC change threshold. (uA)

dd: 2 bytes; Setting the VDC change threshold. (mV)

Example:

- Downlink Payload: 09 01 00 3C 0B B8 01 F4 // Equal to AT+ROC=1,60,3000, 500

- Downlink Payload: 09 01 00 3C 0B B8 00 00 // Equal to AT+ROC=1,60,3000,0

- Downlink Payload: 09 02 00 3C 0B B8 00 00 // Equal to AT+ROC=2,60,3000,0

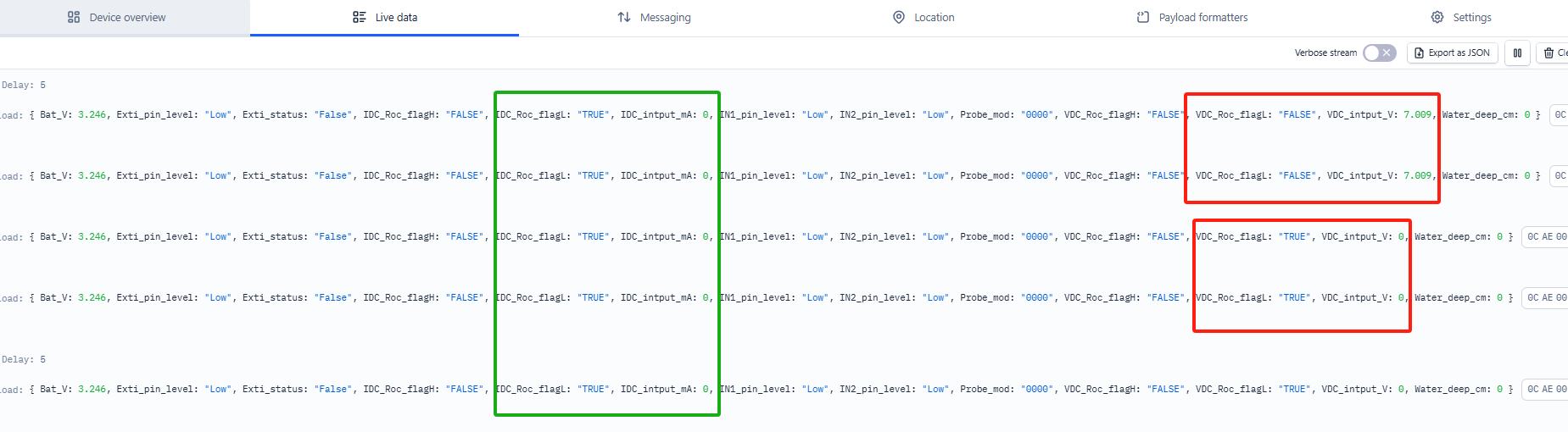

Screenshot of parsing example in TTN:

- AT+ROC=1,60,3000, 500.

2.8.2.2 Over-threshold alarm mode

Feature: Monitors whether the IDC/VDC exceeds the threshold by setting the detection period and threshold. Alarm if the threshold is exceeded.

AT Command: AT+ROC=3,a,b,c,d,e

| Command Example | Parameters | Response/Explanation |

|---|---|---|

| AT+ROC=? | Show current ROC setting | 0,0,0,0(default) |

AT+ROC=3,a,b,c,d,e | a: Set the detection interval | Range: 0~65535s |

| b: Set the IDC alarm trigger condition | 0: Less than the set IDC threshold, Alarm | |

c: IDC alarm threshold | Unit: uA | |

| d: Set the VDC alarm trigger condition | 0: Less than the set VDC threshold, Alarm | |

| e: VDC alarm threshold | Unit: mV |

Example:

- AT+ROC=3,60,0,3000,0,5000 // The data is checked every 60 seconds. If the IDC is less than 3mA or the VDC is less than 5000mV, an alarm is generated.

- AT+ROC=3,180,1,3000,1,5000 // The data is checked every 180 seconds. If the IDC is greater than 3mA or the VDC is greater than 5000mV, an alarm is generated.

- AT+ROC=3,300,0,3000,1,5000 // The data is checked every 300 seconds. If the IDC is less than 3mA or the VDC is greater than 5000mV, an alarm is generated.

Downlink Command: 0x09 03 aa bb cc dd ee

Format: Function code (0x09) followed by 03 and the remaining 5 bytes.

aa: 2 bytes; Set the detection interval.(second)

bb: 1 byte; Set the IDC alarm trigger condition.

cc: 2 bytes; IDC alarm threshold.(uA)

dd: 1 byte; Set the VDC alarm trigger condition.

ee: 2 bytes; VDC alarm threshold.(mV)

Example:

- Downlink Payload: 09 03 00 3C 00 0B B8 00 13 38 // Equal to AT+ROC=3,60,0,3000,0,5000

- Downlink Payload: 09 03 00 b4 01 0B B8 01 13 38 // Equal to AT+ROC=3,60,1,3000,1,5000

- Downlink Payload: 09 03 01 2C 00 0B B8 01 13 38 // Equal to AT+ROC=3,60,0,3000,1,5000

Screenshot of parsing example in TTN:

- AT+ROC=3,60,0,3000,0,5000

2.9 Firmware Change Log

Firmware download link:

https://www.dropbox.com/sh/gf1glloczbzz19h/AABbuYI4WY6VdAmpXo6o1V2Ka?dl=0

3. Configure PS-LB/LS

3.1 Configure Methods

PS-LB/LS supports below configure method:

- AT Command via Bluetooth Connection (Recommand Way): BLE Configure Instruction.

- AT Command via UART Connection : See FAQ.

- LoRaWAN Downlink. Instruction for different platforms: See IoT LoRaWAN Server section.

3.2 General Commands

These commands are to configure:

- General system settings like: uplink interval.

- LoRaWAN protocol & radio related command.

They are same for all Dragino Devices which support DLWS-005 LoRaWAN Stack. These commands can be found on the wiki:

http://wiki.dragino.com/xwiki/bin/view/Main/End%20Device%20AT%20Commands%20and%20Downlink%20Command/

3.3 Commands special design for PS-LB/LS

These commands only valid for PS-LB/LS, as below:

3.3.1 Set Transmit Interval Time

Feature: Change LoRaWAN End Node Transmit Interval.

AT Command: AT+TDC

| Command Example | Function | Response |

|---|---|---|

| AT+TDC=? | Show current transmit Interval | 30000 |

| AT+TDC=60000 | Set Transmit Interval | OK |

Downlink Command: 0x01

Format: Command Code (0x01) followed by 3 bytes time value.

If the downlink payload=0100003C, it means set the END Node's Transmit Interval to 0x00003C=60(S), while type code is 01.

- Example 1: Downlink Payload: 0100001E // Set Transmit Interval (TDC) = 30 seconds

- Example 2: Downlink Payload: 0100003C // Set Transmit Interval (TDC) = 60 seconds

3.3.2 Set Interrupt Mode

Feature, Set Interrupt mode for GPIO_EXIT.

AT Command: AT+INTMOD

| Command Example | Function | Response |

|---|---|---|

| AT+INTMOD=? | Show current interrupt mode | 0 |

| AT+INTMOD=2 | Set Transmit Interval | OK |

Downlink Command: 0x06

Format: Command Code (0x06) followed by 3 bytes.

This means that the interrupt mode of the end node is set to 0x000003=3 (rising edge trigger), and the type code is 06.

- Example 1: Downlink Payload: 06000000 // Turn off interrupt mode

- Example 2: Downlink Payload: 06000003 // Set the interrupt mode to rising edge trigger

3.3.3 Set the output time

Feature, Control the output 3V3 , 5V or 12V.

AT Command: AT+3V3T

| Command Example | Function | Response |

|---|---|---|

| AT+3V3T=? | Show 3V3 open time. | 0 |

| AT+3V3T=0 | Normally open 3V3 power supply. | OK |

| AT+3V3T=1000 | Close after a delay of 1000 milliseconds. | OK |

| AT+3V3T=65535 | Normally closed 3V3 power supply. | OK |

AT Command: AT+5VT

| Command Example | Function | Response |

|---|---|---|

| AT+5VT=? | Show 5V open time. | 0 |

| AT+5VT=0 | Normally closed 5V power supply. | OK |

| AT+5VT=1000 | Close after a delay of 1000 milliseconds. | OK |

| AT+5VT=65535 | Normally open 5V power supply. | OK |

AT Command: AT+12VT

| Command Example | Function | Response |

|---|---|---|

| AT+12VT=? | Show 12V open time. | 0 |

| AT+12VT=0 | Normally closed 12V power supply. | OK |

| AT+12VT=500 | Close after a delay of 500 milliseconds. | OK |

Downlink Command: 0x07

Format: Command Code (0x07) followed by 3 bytes.

The first byte is which power, the second and third bytes are the time to turn on.

- Example 1: Downlink Payload: 070101F4 ---> AT+3V3T=500

- Example 2: Downlink Payload: 0701FFFF ---> AT+3V3T=65535

- Example 3: Downlink Payload: 070203E8 ---> AT+5VT=1000

- Example 4: Downlink Payload: 07020000 ---> AT+5VT=0

- Example 5: Downlink Payload: 070301F4 ---> AT+12VT=500

- Example 6: Downlink Payload: 07030000 ---> AT+12VT=0

Note: Before v1.2, the maximum settable time of 3V3T, 5VT and 12VT is 65535 milliseconds. After v1.2, the maximum settable time of 3V3T, 5VT and 12VT is 180 seconds.

Therefore, the corresponding downlink command is increased by one byte to five bytes.

Example:

- 120s=120000ms(D) =0x01D4C0(H), Downlink Payload: 07 01 01 D4 C0 ---> AT+3V3T=120000

- 100s=100000ms(D) =0x0186A0(H), Downlink Payload: 07 02 01 86 A0 ---> AT+5VT=100000

- 80s=80000ms(D) =0x013880(H), Downlink Payload: 07 03 01 38 80 ---> AT+12VT=80000

3.3.4 Set the Probe Model

Users need to configure this parameter according to the type of external probe. In this way, the server can decode according to this value, and convert the current value output by the sensor into water depth or pressure value.

AT Command: AT +PROBE

AT+PROBE=aabb

When aa=00, it is the water depth mode, and the current is converted into the water depth value; bb is the probe at a depth of several meters.

When aa=01, it is the pressure mode, which converts the current into a pressure value;

bb represents which type of pressure sensor it is.

(A->01,B->02,C->03,D->04,E->05,F->06,G->07,H->08,I->09,J->0A,K->0B,L->0C)

When aa=02, it is the Differential Pressure Sensor , which converts the current into a pressure value;

bb represents which type of pressure sensor it is.

(0~100Pa->01,0~200Pa->02,0~300Pa->03,0~1KPa->04,0~2KPa->05,0~3KPa->06,0~4KPa->07,0~5KPa->08,0~10KPa->09,-100~ 100Pa->0A,-200~ 200Pa->0B,-1~ 1KPa->0C)

| Command Example | Function | Response |

| AT+PROBE=? | Get or Set the probe model. | 0 OK |

| AT+PROBE=0003 | Set water depth sensor mode, 3m type. | OK |

AT+PROBE=000A | Set water depth sensor mode, 10m type. | OK |

| AT+PROBE=0064 | Set water depth sensor mode, 100m type. | OK |

| AT+PROBE=0101 | Set pressure transmitters mode, first type(A). | OK |

| AT+PROBE=0000 | Initial state, no settings. | OK |

Downlink Command: 0x08

Format: Command Code (0x08) followed by 2 bytes.

- Example 1: Downlink Payload: 080003 ---> AT+PROBE=0003

- Example 2: Downlink Payload: 080101 ---> AT+PROBE=0101

3.3.5 Multiple collections are one uplink (Since firmware V1.1)

Added AT+STDC command to collect the voltage of VDC_INPUT/IDC_INPUT multiple times and upload it at one time.

AT Command: AT +STDC

AT+STDC=aa,bb,cc

aa:

0: means disable this function and use TDC to send packets.

1: means that the function is enabled to send packets by collecting VDC data for multiple times.

2: means that the function is enabled to send packets by collecting IDC data for multiple times.

bb: Each collection interval (s), the value is 1~65535

cc: the number of collection times, the value is 1~120

| Command Example | Function | Response |

| AT+STDC=? | Get the mode of multiple acquisitions and one uplink. | 1,10,18 OK |

| AT+STDC=1,10,18 | Set the mode of multiple acquisitions and one uplink, collect once every 10 seconds, and report after 18 times. | Attention:Take effect after ATZ |

| AT+STDC=0, 0,0 | Use the TDC interval to send packets.(default)

| Attention:Take effect after ATZ |

Downlink Command: 0xAE

Format: Command Code (0xAE) followed by 4 bytes.

- Example 1: Downlink Payload: AE 01 02 58 12 ---> AT+STDC=1,600,18

3.4 Print data entries base on page(Since v1.1.0)

Feature: Print the sector data from start page to stop page (max is 416 pages).

AT Command: AT+PDTA

| Command Example | Function |

AT+PDTA=1,1 | Stop Tx events when read sensor data 8031000 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031010 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031020 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031030 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031040 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031050 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031060 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 8031070 1970/1/1 00:00:00 0 in1:low in2:low exti:low status:false vdc:0.000 idc:0.000 proble:0000 water_deep:0.000 Start Tx events OK |

Downlink Command:

No downlink commands for feature

3.5 Print last few data entries(Since v1.1.0)

Feature: Print the last few data entries

AT Command: AT+PLDTA

| Command Example | Function |

AT+PLDTA=10 | Stop Tx events when read sensor data 0001 2025/5/19 06:16:50 3246 in1:low in2:low exti:low status:false vdc:3.352 idc:0.000 proble:0000 water_deep:0.000 0002 2025/5/19 06:17:50 3246 in1:low in2:low exti:low status:false vdc:3.352 idc:0.000 proble:0000 water_deep:0.000 0003 2025/5/19 06:18:50 3246 in1:low in2:low exti:low status:false vdc:3.352 idc:0.000 proble:0000 water_deep:0.000 0004 2025/5/19 06:19:50 3246 in1:low in2:low exti:low status:false vdc:3.352 idc:0.000 proble:0000 water_deep:0.000 0005 2025/5/19 06:20:50 3246 in1:low in2:low exti:low status:false vdc:3.352 idc:0.000 proble:0000 water_deep:0.000 0006 2025/5/19 06:21:50 3246 in1:low in2:low exti:low status:false vdc:3.351 idc:0.000 proble:0000 water_deep:0.000 0007 2025/5/19 06:22:50 3240 in1:low in2:low exti:low status:false vdc:3.351 idc:0.000 proble:0000 water_deep:0.000 0008 2025/5/19 06:26:44 3276 in1:low in2:low exti:low status:false vdc:3.385 idc:0.000 proble:0000 water_deep:0.000 0009 2025/5/19 06:27:36 3246 in1:low in2:low exti:low status:false vdc:3.351 idc:0.000 proble:0000 water_deep:0.000 0010 2025/5/19 06:28:36 3240 in1:low in2:low exti:low status:false vdc:3.351 idc:0.000 proble:0000 water_deep:0.000 Start Tx events OK |

Downlink Command:

No downlink commands for feature

3.6 Clear Flash Record(Since v1.1.0)

Feature: Clear flash storage for data log feature.

AT Command: AT+CLRDTA

| Command Example | Function | Response |

| AT+CLRDTA | Clear date record | Clear all stored sensor data… OK |

Downlink Command: 0xA3

- Example: 0xA301 // Same as AT+CLRDTA

4. Battery & Power Consumption

PS-LB use ER26500 + SPC1520 battery pack and PS-LS use 3000mAh Recharable Battery with Solar Panel. See below link for detail information about the battery info and how to replace.

Battery Info & Power Consumption Analyze .

5. OTA firmware update

Please see this link for how to do OTA firmware update: http://wiki.dragino.com/xwiki/bin/view/Main/Firmware%20OTA%20Update%20for%20Sensors/

6. FAQ

6.1 How to use AT Command via UART to access device?

6.2 How to update firmware via UART port?

6.3 How to change the LoRa Frequency Bands/Region?

You can follow the instructions for how to upgrade image.

When downloading the images, choose the required image file for download.

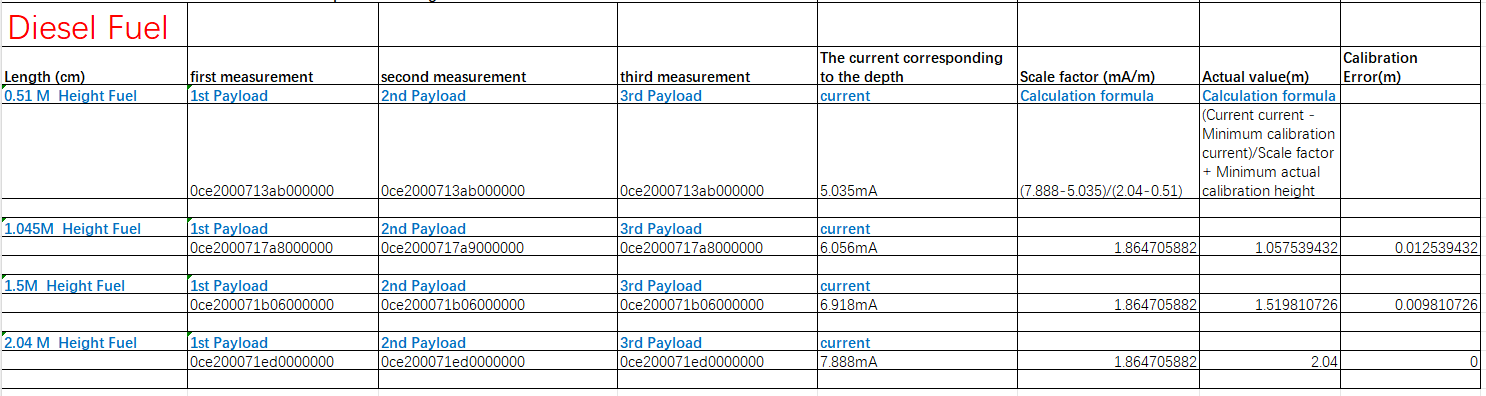

6.4 How to measure the depth of other liquids other than water?

Test the current values at the depth of different liquids and convert them to a linear scale.

Replace its ratio with the ratio of water to current in the decoder.

Example:

Measure the corresponding current of the sensor when the liquid depth is 2.04m and 0.51m.

Calculate scale factor:

Use these two data to calculate the current and depth scaling factors:(7.888-5.035)/(2.04-0.51)=1.86470588235294

Calculation formula:

Use the calibration formula:(Current current - Minimum calibration current)/Scale factor + Minimum actual calibration height

Actual calculations:

Use this formula to calculate the value corresponding to the current at a depth of 1.5 meters: (6.918-5.035)/1.86470588235294+0.51=1.519810726

Error:

0.009810726

6.5 Cable & Probe Material Compatibility(Immersion type)

Since the installation method of immersion sensors requires immersion in a liquid environment, the discussion of liquids that can be safely installed is very important.

The material of the immersed part of the immersion sensor:

- Cable Jacket: Black polyurethane (PU) – Resistant to water, oils, and mild chemicals.

- Probe Material: 316 stainless steel – Corrosion-resistant in most industrial/marine environments.

Chemical Compatibility:

- Polyurethane (PU) Cable: Resists water, oils, fuels, and mild chemicals but may degrade with prolonged exposure to strong acids, bases, or solvents (e.g., acetone, chlorinated hydrocarbons).

- 316 Stainless Steel Probe: Suitable for water, seawater, mild acids/alkalis, and industrial fluids. Avoid highly concentrated acids (e.g., hydrochloric acid) or chlorides at high temperatures.

Chemical Resistance Chart for Polyurethane (PU) Cable

Chemical Resistance Chart for 316 Stainless Steel Probe

7. Troubleshooting

7.1 Water Depth Always shows 0 in payload

If your device's IDC_intput_mA is normal, but your reading always shows 0, please refer to the following points:

1. Please set it to mod1

2. Please set the command AT+PROBE according to the model of your sensor

3. Check the connection status of the sensor

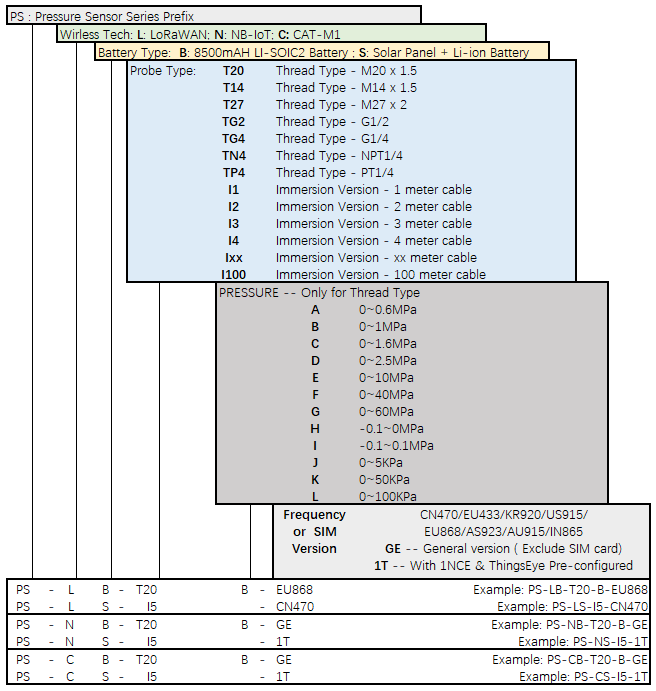

8. Order Info

8.1 Thread Installation Type & Immersion Type Pressure Sensor

Part Number: PS-LB/LS-Txx-YY or PS-LB/LS-Ixx-YY

XX: Pressure Range and Thread Type

YY: The default frequency band

- YY: Frequency Bands, options: EU433,CN470,EU868,IN865,KR920,AS923,AU915,US915

8.2 Wireless Differential Air Pressure Sensor

Part Number: PS-LB-Dxx-YY or PS-LS-Dxx-YY

XX: Differential Pressure Range

YY: The default frequency band

- YY: Frequency Bands, options: EU433,CN470,EU868,IN865,KR920,AS923,AU915,US915

9. Packing Info

Package Includes:

- PS-LB/LS-Txx/Ixx, PS-LB/LS-Dxx LoRaWAN Pressure Sensor

Dimension and weight:

- Device Size: cm

- Device Weight: g

- Package Size / pcs : cm

- Weight / pcs : g

10. Support

- Support is provided Monday to Friday, from 09:00 to 18:00 GMT+8. Due to different timezones we cannot offer live support. However, your questions will be answered as soon as possible in the before-mentioned schedule.

- Provide as much information as possible regarding your enquiry (product models, accurately describe your problem and steps to replicate it etc) and send a mail to Support@dragino.cc.