LSPH01 -- LoRaWAN Soil pH Sensor User Manual

Table of Contents:

- 1. Introduction

- 2. Configure LSPH01 to connect to LoRaWAN network

- 3. Configure LSPH01 via AT Command or LoRaWAN Downlink

- 4. Battery & Power Consumption

- 5. Use AT Command

- 6. FAQ

- 7. Trouble Shooting

- 8. Order Info

- 9. Packing Info

- 10. Support

1. Introduction

1.1 What is LoRaWAN Soil pH Sensor

The Dragino LSPH01 is a LoRaWAN Soil pH Sensor for IoT of Agriculture. It is designed to measure the soil PH and soil temperature, so to send to the platform to analyze the soil acid or alkali level. The probe is IP68 waterproof.

LSPH01 probe is made by Solid AgCl reference electrode and Pure metal pH sensitive electrode. It can detect soil's pH with high accuracy and stable value. The LSPH01 probe can be buried into soil for long time use.

The LoRa wireless technology used in LSPH01 allows device to send data and reach extremely long ranges at low data-rates. It provides ultra-long range spread spectrum communication and high interference immunity whilst minimizing current consumption.

LSPH01 is powered by 8500mAh Li-SOCI2 battery, it is designed for long term use up to 5 years.

Each LSPH01 is pre-load with a set of unique keys for LoRaWAN registrations, register these keys to local LoRaWAN server and it will auto connect after power on.

1.2 Features

- LoRaWAN 1.0.3 Class A

- Ultra-low power consumption

- Monitor soil pH with temperature compensation.

- Monitor soil temperature

- Monitor Battery Level

- Support pH calibration by end user

- Bands: CN470/EU433/KR920/US915/EU868/AS923/AU915/IN865

- AT Commands to change parameters

- Uplink on periodically

- Downlink to change configure

- IP66 Waterproof Enclosure

- IP68 rate for the Sensor Probe

- 8500mAh Battery for long term use

1.3 Probe Specification

Soil pH:

- Range: 3 ~ 10 pH

- Resolution: 0.01 pH

- Accuracy: ±2% under (0~50 ℃, Accuracy will poor under 0 due to frozen)

- Temperature Compensation Range: 0 ~ 50℃

- IP68 Protection

- Length: 3.5 meters

Soil Temperature:

- Range -40℃~85℃

- Resolution: 0.1℃

- Accuracy: <±0.5℃(-10℃~40℃),<±0.8℃ (others)

- IP68 Protection

- Length: 3.5 meters

1.4 Applications

- Smart Agriculture

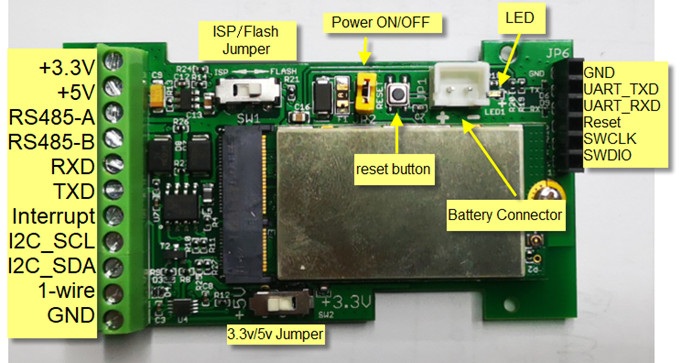

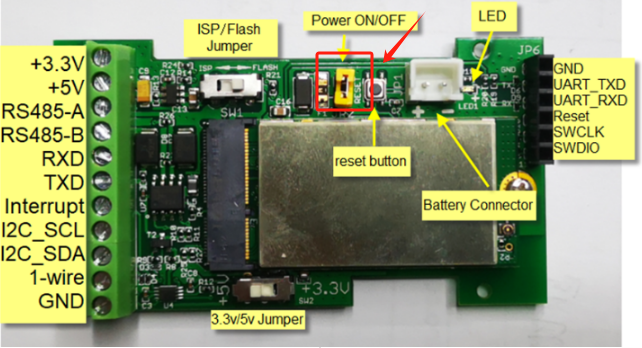

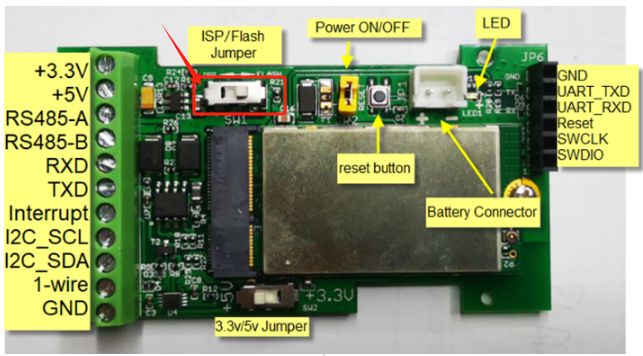

1.5 Pin mapping and power on

2. Configure LSPH01 to connect to LoRaWAN network

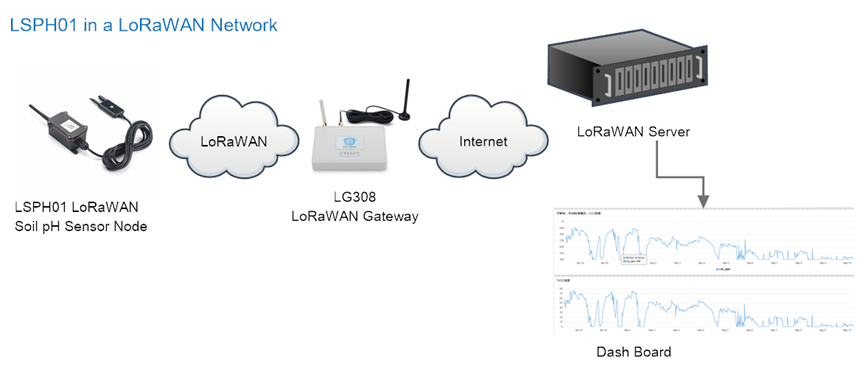

2.1 How it works

The LSPH01 is configured as LoRaWAN OTAA Class A mode by default. It has OTAA keys to join LoRaWAN network. To connect a local LoRaWAN network, you need to input the OTAA keys in the LoRaWAN IoT server and power on the LSPH01. It will automatically join the network via OTAA and start to send the sensor value. The default uplink interval is 20 minutes.

In case you can't set the OTAA keys in the LoRaWAN OTAA server, and you have to use the keys from the server, you can use AT Commands to set the keys in the LSPH01.

2.2 Quick guide to connect to LoRaWAN server (OTAA)

Following is an example for how to join the TTN v3 LoRaWAN Network. Below is the network structure; we use the LG308 as a LoRaWAN gateway in this example.

The LG308 is already set to connected to TTN network , so what we need to now is configure the TTN server.

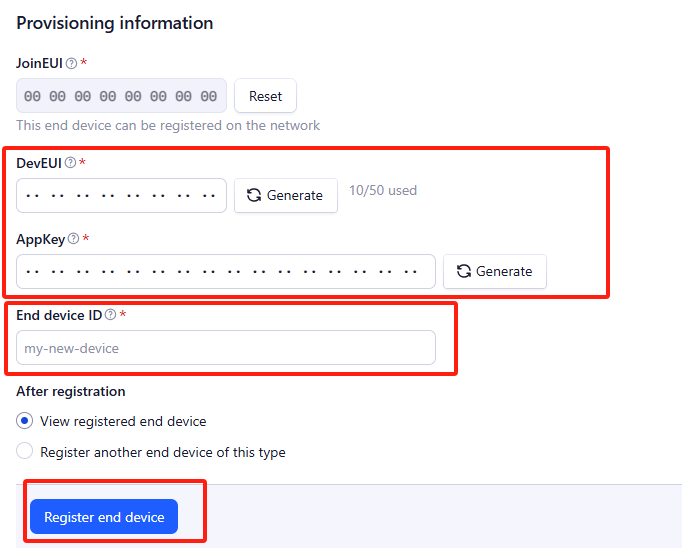

Step 1: Create a device in TTN with the OTAA keys from LSPH01.

Each LSPH01 is shipped with a sticker with the default device EUI as below:

You can enter this key in the LoRaWAN Server portal. Below is TTN screen shot:

Create the application.

Add devices to the created Application.

Enter end device specifics manually.

Add DevEUI and AppKey. Customize a platform ID for the device.

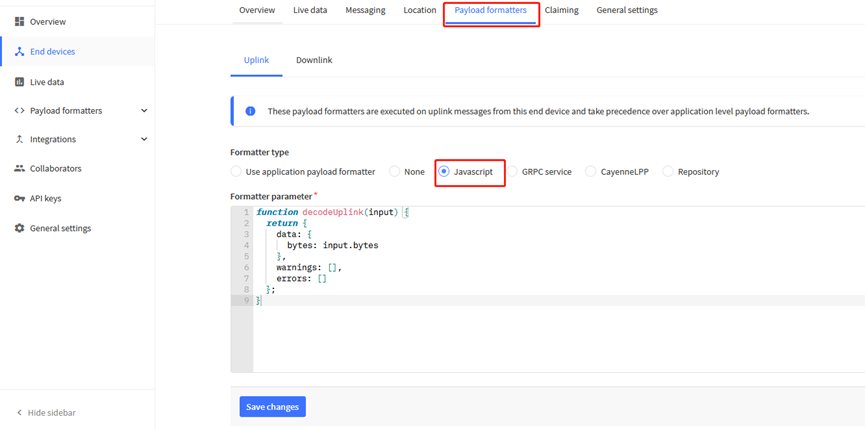

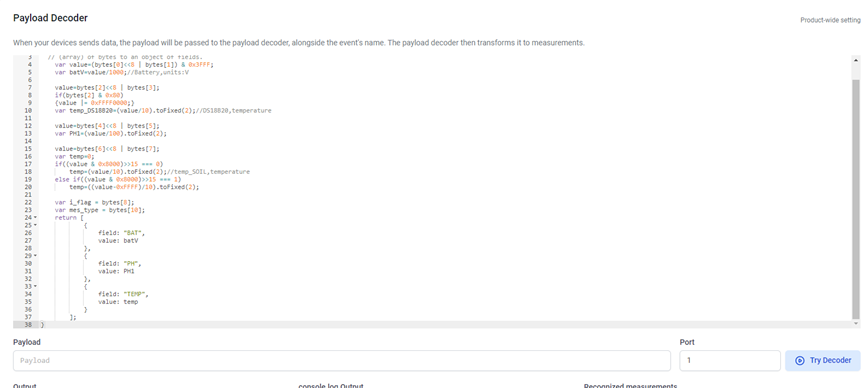

Step 2: Add decoder.

In TTN, user can add a custom payload so it shows friendly reading.

Click this link to get the decoder: https://github.com/dragino/dragino-end-node-decoder/tree/main/

Below is TTN screen shot:

Step 3: Power on LSPH01

Put a Jumper on JP2 to power on the device. ( The Switch must be in FLASH position).

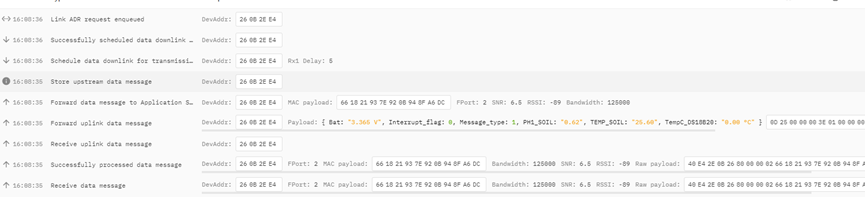

The LSPH01 will auto join to the TTN network. After join success, it will start to upload messages to TTN and you can see the messages in the panel.

2.3 Uplink Payload

LSPH01 will uplink payload via LoRaWAN with below payload format:

Uplink payload includes in total 11 bytes.

Normal uplink payload:

Size(bytes) | 2 | 2 | 2 | 2 | 1 | 1 | 1 |

|---|---|---|---|---|---|---|---|

| Value | BAT | Soil pH | Soil Temperature | Reserve |

2.3.1 Battery Info

Check the battery voltage for LSPH01.

Ex1: 0x0B45 = 2885mV

Ex2: 0x0B49 = 2889mV

2.3.2 DS18B20 Temperature sensor

This is optional, user can connect external DS18B20 sensor to the +3.3v, 1-wire and GND pin . and this field will report temperature.

Example:

If payload is: 0105H: (0105 & FC00 == 0), temp = 0105H /10 = 26.1 degree

If payload is: FF3FH : (FF3F & FC00 == 1) , temp = (FF3FH - 65536)/10 = -19.3 degrees.

2.3.3 Soil pH

Range: 0 ~ 14 pH

Example:

0x02B7(H) = 695(D) = 6.95pH

2.3.4 Soil Temperature

Get Soil Temperature

Example:

If payload is: 0105H: (0105 & FC00 == 0), temp = 0105H /10 = 26.1 degree

If payload is: FF3FH : (FF3F & FC00 == 1) , temp = (FF3FH - 65536)/10 = -19.3 degrees.

2.3.5 Interrupt Pin

This data field shows if this packet is generated by interrupt or not. Click here for the hardware and software set up.

Example:

0x00: Normal uplink packet.

0x01: Interrupt Uplink Packet.

2.3.6 Message Type

For a normal uplink payload, the message type is always 0x01.

Valid Message Type:

| Message Type Code | Description | Payload |

|---|---|---|

| 0x01 | Normal Uplink | Normal Uplink Payload |

| 0x02 | Reply configures info | Configure Info Payload |

| 0x03 | Reply Calibration Info | Calibration Payload |

2.3.7 Decode payload in The Things Network

While using TTN network, you can add the payload format to decode the payload.

The payload decoder function for TTN is here:

LSPH01 TTN Payload Decoder: https://github.com/dragino/dragino-end-node-decoder

2.4 Uplink Interval

The LSPH01 by default uplink the sensor data every 20 minutes. User can change this interval by AT Command or LoRaWAN Downlink Command. See this link: Change Uplink Interval

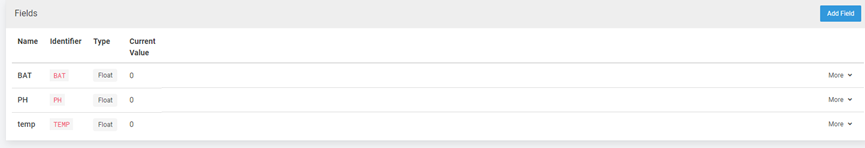

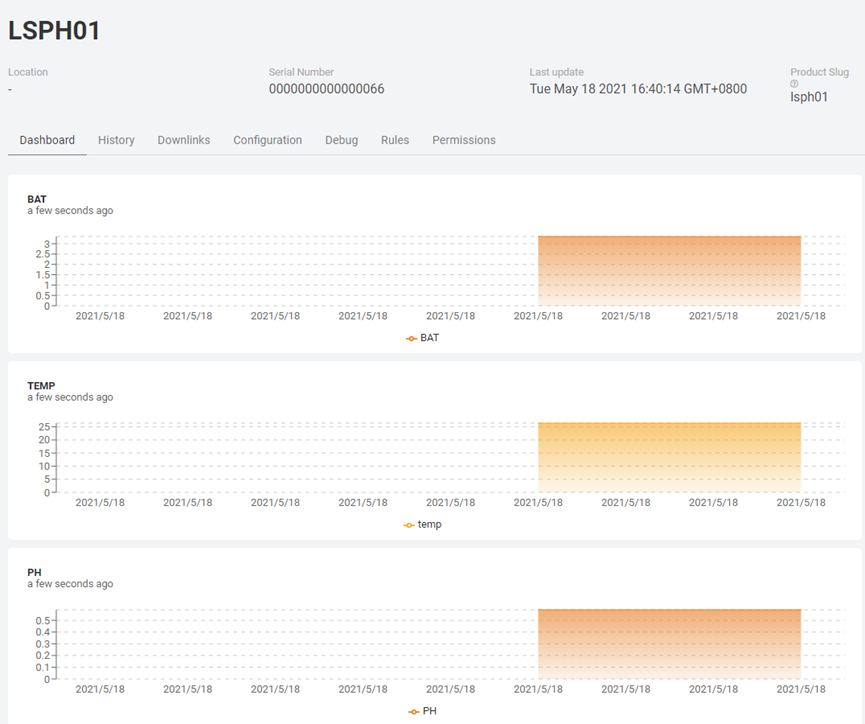

2.5 Show Data in DataCake IoT Server

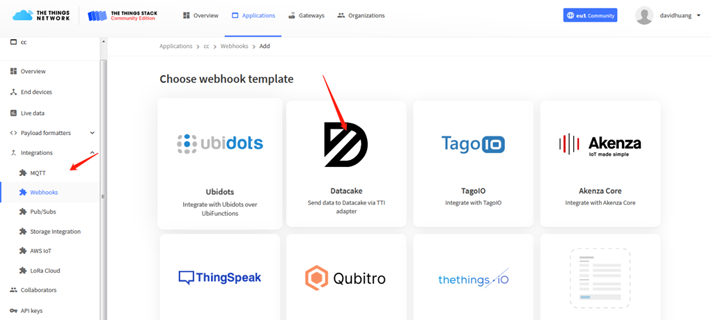

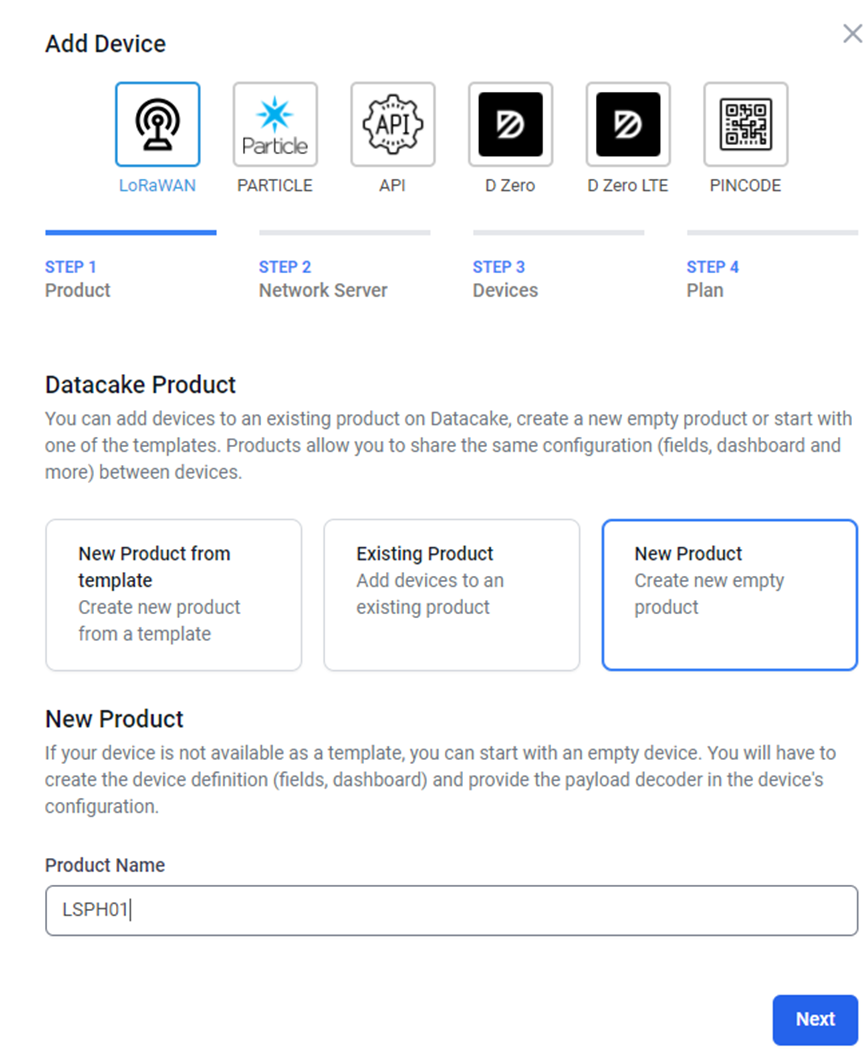

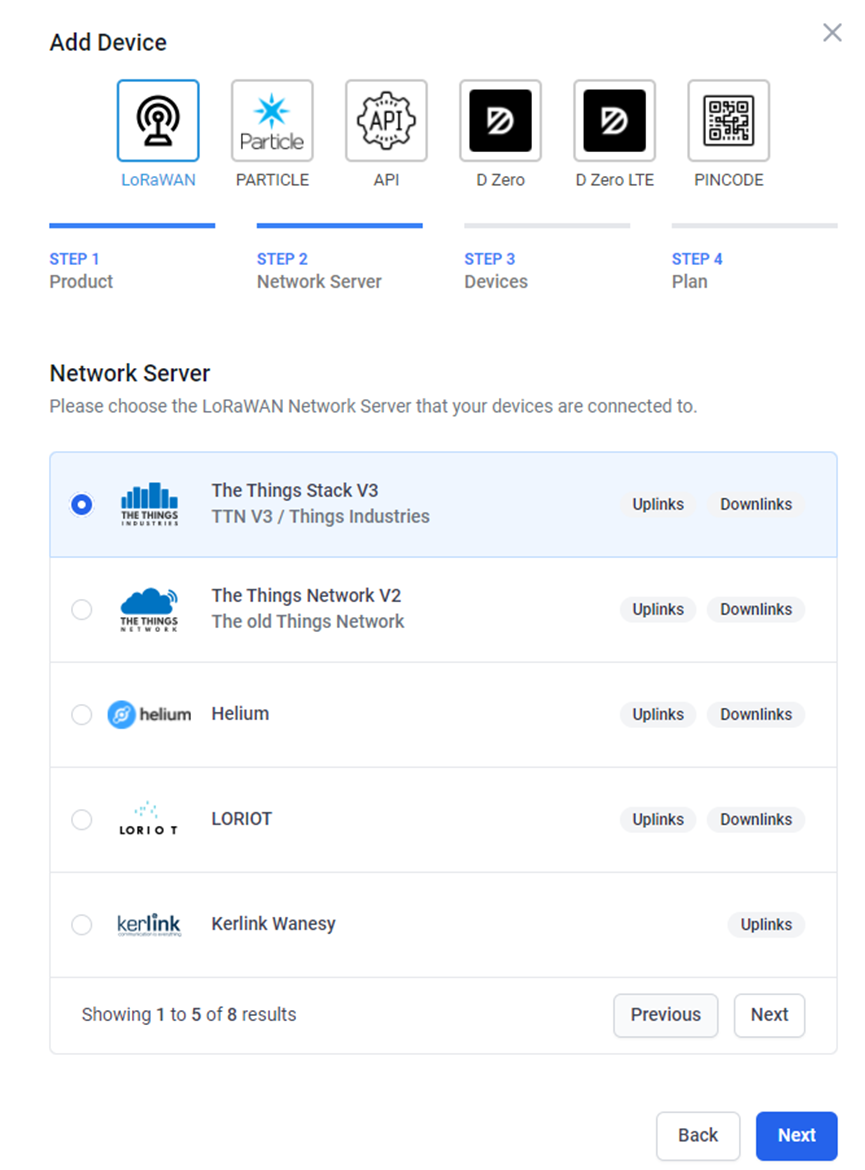

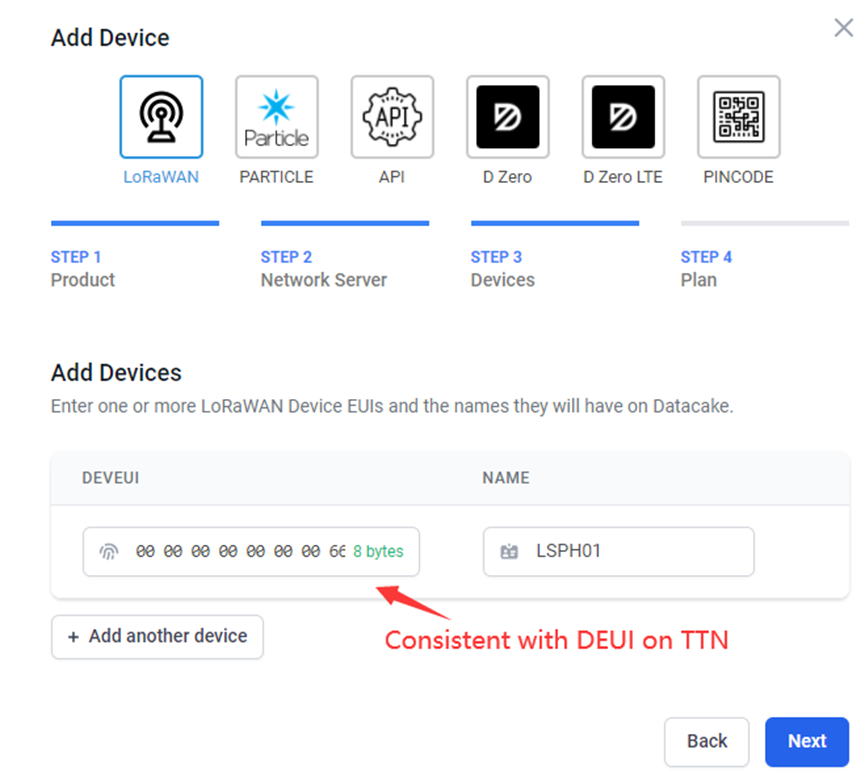

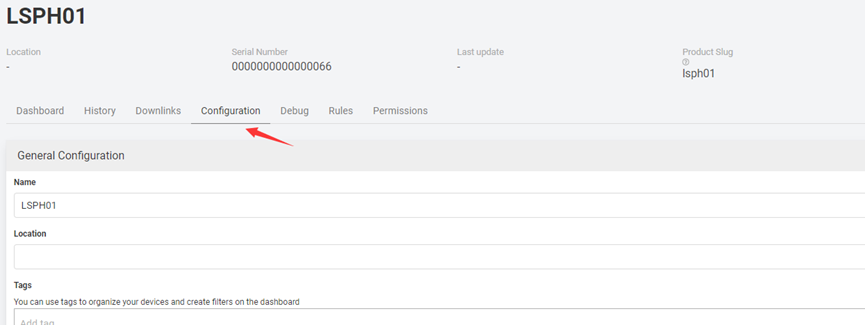

DATACAKE provides a human friendly interface to show the sensor data, once we have data in TTN, we can use DATACAKE to connect to TTN and see the data in DATACAKE. Below are the steps:

Step 1: Be sure that your device is programmed and properly connected to the network at this time.

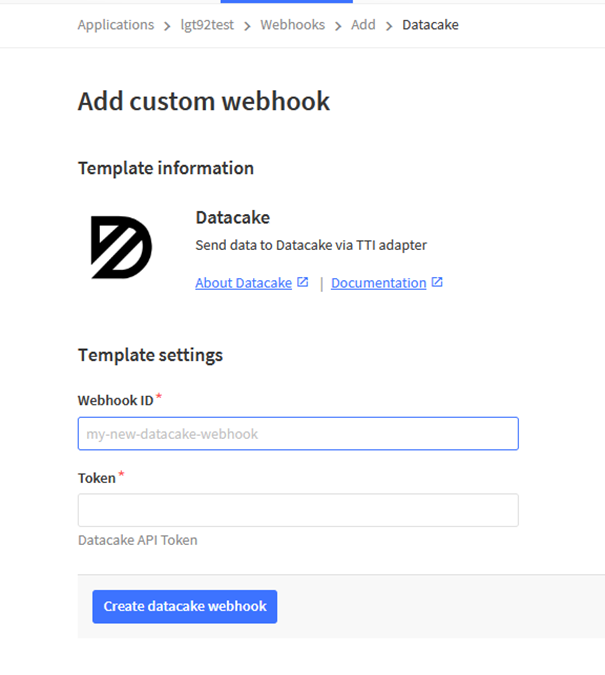

Step 2: To configure the Application to forward data to DATACAKE you will need to add integration. To add the DATACAKE integration, perform the following steps:

Step 3: Create an account or log in Datacake.

Step 4: Create LSPH01 product.

Step 5: add payload decode

Download Datacake decoder from: https://www.dropbox.com/sh/pj7cgmgqg3gx3ta/AABYFbg1DVOOR9Hmr1mLSBkga?dl=0

After added, the sensor data arrive TTN, it will also arrive and show in Mydevices.

2.6 Installation and Maintain

2.6.1 Before measurement

If the LSPH01 has more than 7 days not use or just clean the pH probe. User should put the probe inside pure water for more than 24 hours for activation. If no put in water, user need to put inside soil for more than 24 hours to ensure the measurement accuracy.

2.6.2 Measurement

Measurement the soil surface:

Choose the proper measuring position. Split the surface soil according to the measured deep.

Put pure water, or rainwater to make the soil of measurement point to moist mud. Remove rocks or hard things.

Slowly insert the probe to the measure point. Don't use large force which will break the probe. Make sure not shake when inserting.

Put soil over the probe after insert. And start to measure.

Measurement inside soil:

Dig a hole with diameter > 20CM.

Insert the probe inside, method like measure the surface.

2.6.3 Maintain Probe

1. pH probe electrode is fragile and no strong. User must avoid strong force or hitting it.

2. After long time use (3~ 6 months). The probe electrode needs to be clean; user can use high grade sandpaper to polish it or put in 5% hydrochloric acid for several minutes. After the metal probe looks like new, user can use pure water to wash it.

3. Probe reference electrode is also no strong, need to avoid strong force or hitting.

4. User should keep reference electrode wet while not use.

5. Avoid the probes to touch oily matter. Which will cause issue in accuracy.

6. The probe is IP68 can be put in water.

2.7 Calibration

Step1 : Clean probe

user can use high grade sandpaper to polish it or put in 5% hydrochloric acid for several minutes. After the metal probe looks new, users can clean it to remove hydrochloric acid or other liquids from the surface.

Step2 : Immerse the sensor in ph buffer solution to make the sensor values stable

User can do calibration for the probe. It is limited to use below pH buffer solution to calibrate: 4.00, 6.86, 9.18. When calibration, user need to clean the electrode and put the probe in the pH buffer solution to wait the value stable ( a new clean electrode might need max 24 hours to be stable).

Note: Only one ph buffer with one of the ph values needs to be calibrated during calibration. Wait for the sensor measurement value to be stable, it does not need to be the same as the ph marked by the ph buffer

Step3 : The numerically stable sensors were calibrated using commands

User can use below command to calibrate.

| pH buffer solution | AT Command to calibrate | Downlink Command | Read Cal Value |

| 4.00 | AT+PHCAL=4 | 0x13 04 | AT+PHCAL=? |

| 6.86 | AT+PHCAL=6 | 0x13 06 | AT+PHCAL=? |

| 9.18 | AT+PHCAL=9 | 0x13 09 | AT+PHCAL=? |

| Factory Default | AT+PHCAL=15 | 0x13 15 | AT+PHCAL=? |

To use the AT COMMAND, refer to this link:

- AT Command via Bluetooth Connection (Recommended): BLE Configure Instruction.

- AT Command via UART Connection : See UART Connection.

To use Downlink, take TTN as an example, please refer to this link:

- LoRaWAN Downlink. Instruction for different platforms: See IoT LoRaWAN Server section.

When the command is successfully used, the node sends a uplink.

This is the payload for uplink

Calibration Payload

Size(bytes) | 1 | 1 | 1 | 7 | 1 |

|---|---|---|---|---|---|

| Value | PH4 Calibrate value | PH6.86 Calibrate value | PH9.18 Calibrate value | Reserve | Message Type |

User can also send 0x14 downlink command to poll the current calibration payload.

| Downlink Control Type | FPort | Type Code | Downlink payload size(bytes) |

|---|---|---|---|

| Get Calibration Version Info | Any | 14 | 2 |

- Reply to the confirmation package: 14 01

- Reply to non-confirmed packet: 14 00

Step4 : After the calibration is completed, its measurement results in this ph buffer solution should be consistent with the numerical value of the command used in the calibration.

Examples:

After using the command AT+PH=9 in 9.18ph buffer

The readout returned by the sensor in 9.18ph buffer should be pH=9

2.8 Frequency Plans

The LSPH01 uses OTAA mode and below frequency plans by default. If user want to use it with different frequency plan, please refer the AT command sets.

2.8.1 EU863-870 (EU868)

Uplink:

868.1 - SF7BW125 to SF12BW125

868.3 - SF7BW125 to SF12BW125 and SF7BW250

868.5 - SF7BW125 to SF12BW125

867.1 - SF7BW125 to SF12BW125

867.3 - SF7BW125 to SF12BW125

867.5 - SF7BW125 to SF12BW125

867.7 - SF7BW125 to SF12BW125

867.9 - SF7BW125 to SF12BW125

868.8 - FSK

Downlink:

Uplink channels 1-9 (RX1)

869.525 - SF9BW125 (RX2 downlink only)

2.8.2 US902-928(US915)

Used in USA, Canada and South America. Frequency band as per definition in LoRaWAN 1.0.3 Regional document.

To make sure the end node supports all sub band by default. In the OTAA Join process, the end node will use frequency 1 from sub-band1, then frequency 1 from sub-band2, then frequency 1 from sub-band3, etc to process the OTAA join.

After Join success, the end node will switch to the correct sub band by:

- Check what sub-band the LoRaWAN server ask from the OTAA Join Accept message and switch to that sub-band

- Use the Join successful sub-band if the server doesn't include sub-band info in the OTAA Join Accept message ( TTN v2 doesn't include)

2.8.3 CN470-510 (CN470)

Used in China, Default use CHE=1

Uplink:

486.3 - SF7BW125 to SF12BW125

486.5 - SF7BW125 to SF12BW125

486.7 - SF7BW125 to SF12BW125

486.9 - SF7BW125 to SF12BW125

487.1 - SF7BW125 to SF12BW125

487.3 - SF7BW125 to SF12BW125

487.5 - SF7BW125 to SF12BW125

487.7 - SF7BW125 to SF12BW125

Downlink:

506.7 - SF7BW125 to SF12BW125

506.9 - SF7BW125 to SF12BW125

507.1 - SF7BW125 to SF12BW125

507.3 - SF7BW125 to SF12BW125

507.5 - SF7BW125 to SF12BW125

507.7 - SF7BW125 to SF12BW125

507.9 - SF7BW125 to SF12BW125

508.1 - SF7BW125 to SF12BW125

505.3 - SF12BW125 (RX2 downlink only)

2.8.4 AU915-928(AU915)

Frequency band as per definition in LoRaWAN 1.0.3 Regional document.

To make sure the end node supports all sub band by default. In the OTAA Join process, the end node will use frequency 1 from sub-band1, then frequency 1 from sub-band2, then frequency 1 from sub-band3, etc to process the OTAA join.

After Join success, the end node will switch to the correct sub band by:

- Check what sub-band the LoRaWAN server ask from the OTAA Join Accept message and switch to that sub-band

- Use the Join successful sub-band if the server doesn't include sub-band info in the OTAA Join Accept message ( TTN v2 doesn't include)

2.8.5 AS920-923 & AS923-925 (AS923)

Default Uplink channel:

923.2 - SF7BW125 to SF10BW125

923.4 - SF7BW125 to SF10BW125

Additional Uplink Channel:

(OTAA mode, channel added by JoinAccept message)

AS920~AS923 for Japan, Malaysia, Singapore:

922.2 - SF7BW125 to SF10BW125

922.4 - SF7BW125 to SF10BW125

922.6 - SF7BW125 to SF10BW125

922.8 - SF7BW125 to SF10BW125

923.0 - SF7BW125 to SF10BW125

922.0 - SF7BW125 to SF10BW125

AS923 ~ AS925 for Brunei, Cambodia, Hong Kong, Indonesia, Laos, Taiwan, Thailand, Vietnam:

923.6 - SF7BW125 to SF10BW125

923.8 - SF7BW125 to SF10BW125

924.0 - SF7BW125 to SF10BW125

924.2 - SF7BW125 to SF10BW125

924.4 - SF7BW125 to SF10BW125

924.6 - SF7BW125 to SF10BW125

Downlink:

Uplink channels 1-8 (RX1)

923.2 - SF10BW125 (RX2)

2.8.6 KR920-923 (KR920)

Default channel:

922.1 - SF7BW125 to SF12BW125

922.3 - SF7BW125 to SF12BW125

922.5 - SF7BW125 to SF12BW125

Uplink: (OTAA mode, channel added by JoinAccept message)

922.1 - SF7BW125 to SF12BW125

922.3 - SF7BW125 to SF12BW125

922.5 - SF7BW125 to SF12BW125

922.7 - SF7BW125 to SF12BW125

922.9 - SF7BW125 to SF12BW125

923.1 - SF7BW125 to SF12BW125

923.3 - SF7BW125 to SF12BW125

Downlink:

Uplink channels 1-7(RX1)

921.9 - SF12BW125 (RX2 downlink only; SF12BW125 might be changed to SF9BW125)

2.8.7 IN865-867 (IN865)

Uplink:

865.0625 - SF7BW125 to SF12BW125

865.4025 - SF7BW125 to SF12BW125

865.9850 - SF7BW125 to SF12BW125

Downlink:

Uplink channels 1-3 (RX1)

866.550 - SF10BW125 (RX2)

2.9 LED Indicator

The LSPH01 has an internal LED which is to show the status of different state.

- The sensor is detected when the device is turned on, and it will flash 4 times quickly when it is detected.

- Blink once when device transmit a packet.

2.10 Firmware Change Log

Firmware download link: https://www.dropbox.com/sh/xtm5tw37mewaw99/AAD0uy06odmreQQ7vMzZYVIGa?dl=0

Firmware Upgrade Method: Firmware Upgrade Instruction

3. Configure LSPH01 via AT Command or LoRaWAN Downlink

Use can configure LSPH01 via AT Command or LoRaWAN Downlink.

AT Command Connection: See FAQ.

LoRaWAN Downlink instruction for different platforms: IoT LoRaWAN Server

There are two kinds of commands to configure LSPH01, they are:

General Commands.

These commands are to configure:

General system settings like: uplink interval.

LoRaWAN protocol & radio related command.

They are same for all Dragino Device which support DLWS-005 LoRaWAN Stack. These commands can be found on the wiki: End Device AT Commands and Downlink Command

Commands special design for LSPH01

These commands only valid for LSPH01, as below:

3.1 Set Transmit Interval Time

Feature: Change LoRaWAN End Node Transmit Interval.

AT Command: AT+TDC

| Command Example | Function | Response |

|---|---|---|

| AT+TDC=? | Show current transmit Interval | 30000 |

| AT+TDC=60000 | Set Transmit Interval | OK |

Downlink Command: 0x01

Format: Command Code (0x01) followed by 3 bytes time value.

If the downlink payload=0100003C, it means set the END Node's Transmit Interval to 0x00003C=60(S), while type code is 01.

Example 1: Downlink Payload: 0100001E // Set Transmit Interval (TDC) = 30 seconds

Example 2: Downlink Payload: 0100003C // Set Transmit Interval (TDC) = 60 seconds

3.2 Set Interrupt Mode

Feature, Set Interrupt mode for GPIO_EXIT.

AT Command: AT+INTMOD

| Command Example | Function | Response |

|---|---|---|

| AT+INTMOD=? | Show current interrupt mode | 0 |

| AT+INTMOD=2 | Set Transmit Interval | OK |

Downlink Command: 0x06

Format: Command Code (0x06) followed by 3 bytes.

This means that the interrupt mode of the end node is set to 0x000003=3 (rising edge trigger), and the type code is 06.

Example 1: Downlink Payload: 06000000 // Turn off interrupt mode

Example 2: Downlink Payload: 06000003 // Set the interrupt mode to rising edge trigger

3.3 Calibrate Sensor

Detail See Calibration Guide for the user of 0x13 and 0x14 downlink commands

3.4 Get Firmware Version Info

Feature: use downlink to get firmware version.

Downlink Command: 0x26

| Downlink Control Type | FPort | Type Code | Downlink payload size(bytes) |

| Get Firmware Version Info | Any | 26 | 2 |

- Reply to the confirmation package: 26 01

- Reply to non-confirmed packet: 26 00

Device will send an uplink after got this downlink command. With below payload:

Configures info payload:

| Size(bytes) | 1 | 1 | 1 | 1 | 1 | 5 | 1 |

| Value | Software Type | Frequency | Sub-band | Firmware | Sensor Type | Reserve | Message Type |

Software Type: Always 0x03 for LSPH01

Frequency Band:

*0x01: EU868

*0x02: US915

*0x03: IN865

*0x04: AU915

*0x05: KZ865

*0x06: RU864

*0x07: AS923

*0x08: AS923-1

*0x09: AS923-2

*0xa0: AS923-3

Sub-Band: value 0x00 ~ 0x08

Firmware Version: 0x0100, Means: v1.0.0 version

Sensor Type:

0x01: LSE01

0x02: LDDS75

0x03: LDDS20

0x04: LLMS01

0x05: LSPH01

0x06: LSNPK01

0x07: LDDS12

4. Battery & Power Consumption

LSPH01 uses ER26500 + SPC1520 battery pack. See below link for detail information about the battery info and how to replace.

Battery Info & Power Consumption Analyze .

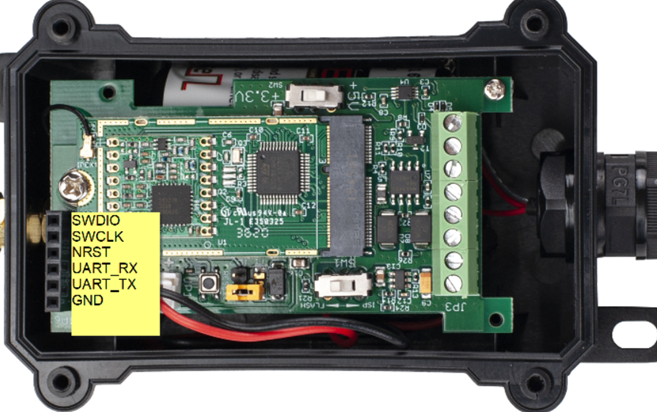

5. Use AT Command

5.1 Access AT Commands

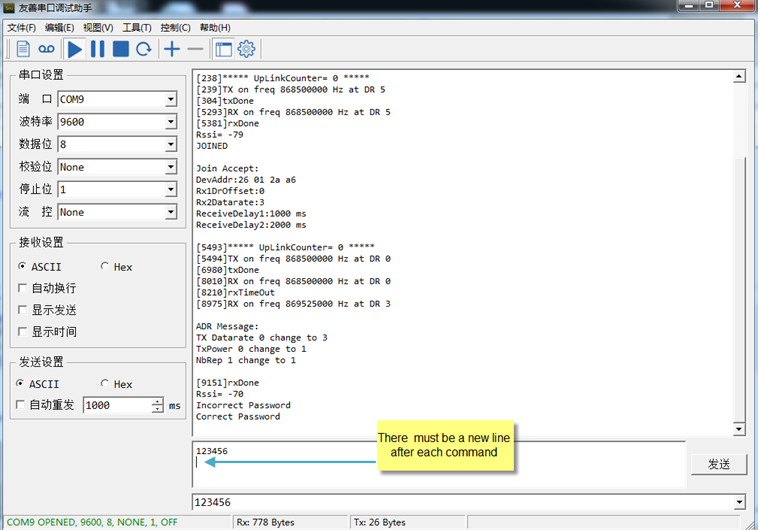

LSPH01 supports AT Command set in the stock firmware. You can use a USB to TTL adapter to connect to LSPH01 for using AT command, as below.

Connection:

USB TTL GND <----> GND

USB TTL TXD <----> UART_RXD

USB TTL RXD <----> UART_TXD

In the PC, you need to set the serial baud rate to 9600 to access the serial console for LSPH01. LSPH01 will output system info once power on as below:

Valid AT Command please check Configure Device.

6. FAQ

6.1 How to change the LoRa Frequency Bands/Region

You can follow the instructions for how to upgrade image.

When downloading the images, choose the required image file for download.

7. Trouble Shooting

7.1 AT Commands input doesn't work

In the case if user can see the console output but can't type input to the device. Please check if you already include the ENTER while sending out the command. Some serial tool doesn't send ENTER while press the send key, user need to add ENTER in their string.

7.2 Possible reasons why the device is unresponsive:

1. Check whether the battery voltage is lower than 2.8V

2. Check whether the jumper of the device is correctly connected

3. Check whether the switch here of the device is at the ISP(The switch can operate normally only when it is in RUN)

7.3 The node cannot read the sensor data

This may be caused by a software firmware(≤1.1.6 version) bug, which we fixed in the latest firmware (>1.0.0 version)

The user can fix this problem via upgrade firmware.

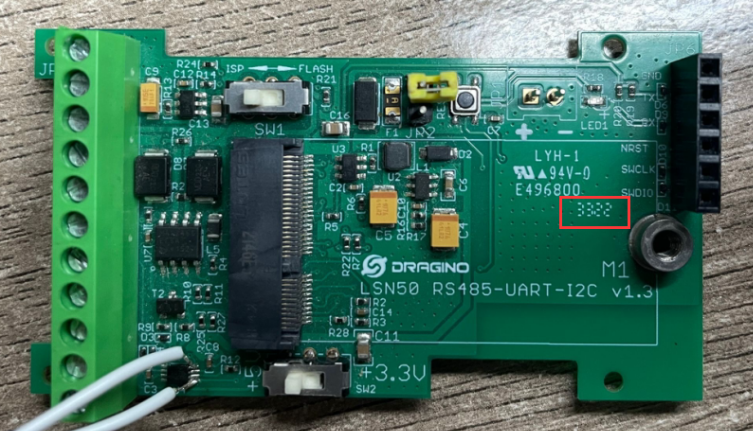

By default, The latest firmware value of POWERIC is 1, while the 3322 version requires POWERIC to be set to 0 in order to function properly

- 1. Check if the hardware version is 3322

If the sensor hardware version is 3322 or earlier, the user can change the POWERIC value to 0 after a firmware upgrade using one of the following methods

a. Using AT command

b. Using Downlink

Please check your hardware production date

The first two digits are the week of the year, and the last two digits are the year.

The number 3322 is the first batch we changed the power IC.

8. Order Info

Part Number: LSPH01-XX

XX: The default frequency band

- AS923: LoRaWAN AS923 band

- AU915: LoRaWAN AU915 band

- EU433: LoRaWAN EU433 band

- EU868: LoRaWAN EU868 band

- KR920: LoRaWAN KR920 band

- US915: LoRaWAN US915 band

- IN865: LoRaWAN IN865 band

- CN470: LoRaWAN CN470 band

9. Packing Info

Package Includes:

- LSPH01 LoRaWAN Soil Ph Sensor x 1

Dimension and weight:

- Device Size: cm

- Device Weight: g

- Package Size / pcs : cm

- Weight / pcs : g

10. Support

- Support is provided Monday to Friday, from 09:00 to 18:00 GMT+8. Due to different timezones we cannot offer live support. However, your questions will be answered as soon as possible in the before-mentioned schedule.

- Provide as much information as possible regarding your enquiry (product models, accurately describe your problem and steps to replicate it etc) and send a mail to support@dragino.com.