Water Quality Sensors

Table of Contents:

- 1. DR-EC Water EC Probe

- 2. DR-PH01 Water PH Sensor

- 3. DR-ORP1 Water ORP Sensor

- 4. DR-DO1 Dissolved Oxygen Sensor

- 5. DR-TS1 Water Turbidity Sensor

- 6. DR-CL Water CL Probe

- 7. Water Quality Sensor Datasheet

1. DR-EC Water EC Probe

1.1 Specification:

- Power Input: DC7~30

- Power Consumption : < 0.5W

- Interface: RS485. 9600 Baud Rate

- EC Range & Resolution:

- ECK1.0 : 0 ~ 2,000 μS/cm Resolution: 1 μS/cm

- ECK10.0 : 10 ~ 20,000 μS/cm Resolution: 10 μS/cm

- EC200 : 1 ~ 200,000 μS/cm Resolution: 1 μS/cm

- EC Accuracy: ±1% FS

- Salinity measurement range

- EC200 :0~70PSU Resolution: 0.1PSU

- Temperature measurement range

- ECK1/ECK10:-20~+60℃; Resolution: 0.1℃

- EC200 :-5~+80℃; Resolution: 0.1℃

- Temperature Accuracy: ±0.5 °C

- Temperature compensation range

- ECK1/ECK10:0~+60℃ (default compensation temperature 25℃)

- EC200:-5~+80℃ (default compensation temperature 25℃)

- Temperature compensation coefficient:Default 0.2

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- ECK200 Continuous monitoring of cross-section water quality, aquaculture, sewage treatment, environmental protection, pharmaceuticals, food, tap water, seawater and other high conductivity environments

- IP Rated: IP68

- Max Pressure: 0.6MPa

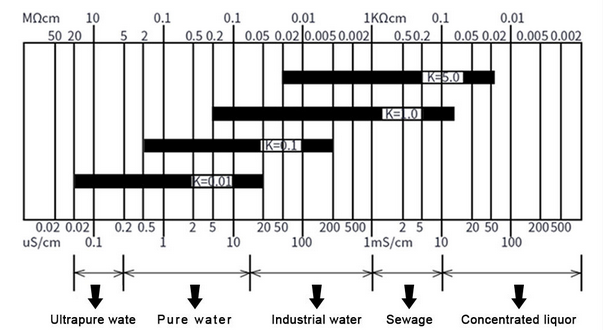

1.2 Application for Different Range

1.3 Wiring

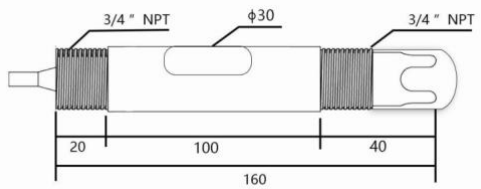

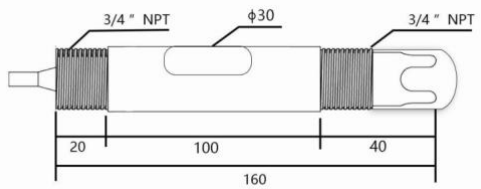

1.4 Mechinical Drawing

ECK1 and ECK10 EC200

1.5 Installation

Electrode installation form:

A: Side wall installation

B: Top flange installation

C: Pipeline bend installation

D: Pipeline bend installation

E: Flow-through installation

F: Submerged installation

Several common installation methods of electrodes

When installing the sensor on site, you should strictly follow the correct installation method shown in the following picture. Incorrect installation method will cause data deviation.

A. Several common incorrect installation methods

Error cause: The electrode joint is too long, the extension part is too short, the sensor is easy to form a dead cavity, resulting in measurement error.

Error cause: Measurement error or instability may occur due to water flow not being able to fill the pipe or air accumulation at high altitudes.

B. Correct installation method

1.6 Maintenance

- The equipment itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself, and contact us as soon as possible.

- If the electrode is not used for a long time, it can generally be stored in a dry place, but it must be placed (stored) in distilled water for several hours before use to activate the electrode. Electrodes that are frequently used can be placed (stored) in distilled water.

- Cleaning of conductivity electrodes: Organic stains on the electrode can be cleaned with warm water containing detergent, or with alcohol. Calcium and magnesium precipitates are best cleaned with 10% citric acid. The electrode plate or pole can only be cleaned by chemical methods or by shaking in water. Wiping the electrode plate will damage the coating (platinum black) on the electrode surface.

- The equipment should be calibrated before each use. It is recommended to calibrate it every 3 months for long-term use. The calibration frequency should be adjusted appropriately according to different application conditions (degree of dirt in the application, deposition of chemical substances, etc.).

1.7 RS485 Commands

RS485 signal (K1 default address 0x12; K10 default address 0x11):

Standard Modbus-RTU protocol, baud rate: 9600; check bit: none; data bit: 8; stop bit: 1

ery.

1.7.1 Query address

send:

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0XFE | 0X03 | 0X00 | 0X50 | 0X00 | 0X00 | 0X51 | 0XD4 |

If you forget the original address of the sensor, you can use the broadcast address 0XFE instead. When using 0XFE, the host can only connect to one slave, which can be used as a method of address query.

response:

| New address | Function code | Data length | CRC16 low | CRC16 high |

|---|---|---|---|---|

| 0X01 | 0X03 | 0X00 | 0X20 | 0XF0 |

1.7.2 Change address

For example: Change the address of the sensor with address 1 to 2, master → slave

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X06 | 0X00 | 0X50 | 0X00 | 0X02 | 0X08 | 0X1A |

If the sensor receives correctly, the data is returned along the original path.

Note: If you forget the original address of the sensor, you can use the broadcast address 0XFE instead. When using 0XFE, the host can only connect to one slave, and the return address is still the original address, which can be used as a method of address query.

1.7.3 Modify intercept

send:

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X06 | 0X00 | 0X23 | 0X00 | 0X01 | 0XF8 | 0X07 |

Change the intercept of the sensor with address 1 to 10 (default 0), which is 0X000A in the command.

response:

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X06 | 0X02 | 0X00 | 0X00 | 0X0A | 0X38 | 0X8F |

1.7.4 Query data

Query the data (EC,temperature) of the sensor (address 11), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X11 | 0X03 | 0X00 | 0X00 | 0X00 | 0X02 | 0XC6 | 0X9B |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | Register 1 Data high | Register 1 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|---|

| 0X11 | 0X03 | 0X04 | 0X02 | 0XAE | 0X01 | 0X64 | 0X8B | 0XD0 |

The address of the EC K10 sensor is 11

The query data command is 11 03 00 00 00 02 C6 9B

For example, the returned data is 11 03 04 02 AE 01 64 8B D0. 02 AE is converted to decimal 686, K=10, EC: 6860uS/cm,temperature: 35.6℃ Convert the returned data to decimal and divide by 10.

Query the data (EC,temperature) of the sensor (address 11), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X12 | 0X03 | 0X00 | 0X00 | 0X00 | 0X02 | 0XC6 | 0XA8 |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | Register 1 Data high | Register 1 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|---|

| 0X12 | 0X03 | 0X04 | 0X02 | 0XAE | 0X01 | 0X64 | 0XB8 | 0XD0 |

The address of the EC K1 sensor is 12

The query data command is 12 03 00 00 00 02 C6 A8

For example, the returned data is 12 03 04 02 AE 01 64 B8 D0. 02 AE is converted to decimal 686, K=1, EC: 686uS/cm,temperature: 35.6℃ Convert the returned data to decimal and divide by 10.

EC200

| Address | Function code | Register Address | Register length | CRC16 low | CRC16 high |

|---|---|---|---|---|---|

| 0X01 | 0X03 | 0X00 0X00 | 0X00 0X04 | 0XC5 | 0XC8 |

response:

| Address | Function code | Number of valid bytes | Register contents | CRC16 low | CRC16 high |

|---|---|---|---|---|---|

| 0X01 | 0X03 | 0X08 | 0X00 0X00 0X1E 0XEF 0X01 0X14 0X00 0X2B | 0X42 | 0X59 |

Conductivity calculation: 0X1EEF=7919=>Conductivity=7919μS/cm

Temperature calculation: 0X0114=276=>Temperature=27.6℃

Salinity calculation: 0X002b=43=>Salinity=4.3PSU

1.7.5 Calibration Method

ECK1 and ECK10.0

This device uses one-point calibration, and you need to prepare a known E standard solution. When mileage K=1, 1~2000 uses 1413μS/cm standard solution, and when mileage K=10, 10~20000 uses 12.88mS/cm standard solution.

The calibration steps are as follows:

(1) Place the electrode in distilled water and clean it. When mileage 1~2000 uses 1413μS/cm standard solution, enter the following calibration command after the data is stable.

| Address | Function code | Address high | Address low | Quantity high | Quantity low | Data length | Data | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|---|---|

| 0X12 | 0X10 | 0X00 | 0X26 | 0X00 | 0X02 | 0X04 | 0X00 | 0XBD | 0XFC |

1413*10 gives 0X00003732

response:

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X12 | 0X10 | 0X00 | 0X26 | 0X00 | 0X02 | 0XA2 | 0XA0 |

(2) Place the electrode in distilled water to clean it. Use 12.88mS/cm standard solution for the range of 10~20000. After the data is stable, enter the following calibration command

| Address | Function code | Address high | Address low | Quantity high | Quantity low | Data length | Data | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|---|---|

| 0X11 | 0X10 | 0X00 | 0X26 | 0X00 | 0X02 | 0X04 | 0X00 | 0X33 | 0X75 |

12880*10 gives 0X01F720

response:

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X11 | 0X06 | 0X00 | 0X26 | 0X00 | 0X02 | 0XEB | 0X50 |

EC200

For the device with address 01, use 1413uS/cm standard solution to calibrate the first point. Send frame: 1413. Convert hexadecimal to 585. Write 0001, 00 00, 0585 to 0x0120, 0x0121, 0x0122 respectively.

| Address | Function code | Register Address | Register length | Data length | Register contents | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X01 0X20 | 0X00 0X03 | 0X06 | 0X00 | 0X1c | 0X25 |

response:

| Address | Function code | Register Address | Register length | Data length | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X01 0X02 | 0X00 0X03 | 0X06 | 0X80 | 0X3e

|

Use 111310uS/cm standard solution to calibrate the second point and send the frame: 111310 is converted into hexadecimal 1b2ce, and 0002, 0001,b2 ce are written to 0x0120, 0x0121, and 0x0122 respectively.

| Address | Function code | Register Address | Register length | Data length | Register contents | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X01 0X20 | 0X00 0X03 | 0X06 | 0X00 | 0X3e | 0X22 |

response:

| Address | Function code | Register Address | Register length | Data length | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X01 0X02 | 0X00 0X03 | 0X06 | 0X80 | 0X3e |

2. DR-PH01 Water PH Sensor

2.1 Specification

- Power Input: DC7~30

- Power Consumption : < 0.5W

- Interface: RS485. 9600 Baud Rate

- pH measurement range: 0~14.00pH; resolution: 0.01pH

- pH measurement error: ±0.15pH

- Repeatability error: ±0.02pH

- Temperature measurement range:0~60°C; resolution: 0.1°C (set temperature for manual temperature compensation, default 25°C)

- Temperature measurement error: ±0.5°C

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Temperature Accuracy: ±0.5 °C

- IP Rated: IP68

- Max Pressure: 0.6MPa

2.2 Wiring

2.3 Mechinical Drawing

2.4 Installation Notice

Do not power on while connect the cables. Double check the wiring before power on.

Installation Photo as reference:

Submerged installation:

The lead wire of the equipment passes through the waterproof pipe, and the 3/4 thread on the top of the equipment is connected to the 3/4 thread of the waterproof pipe with raw tape. Ensure that the top of the equipment and the equipment wire are not flooded.

Pipeline installation:

Connect the equipment to the pipeline through the 3/4 thread.

Sampling:

Take representative water samples according to sampling requirements. If it is inconvenient to take samples, you can also put the electrode into the solution to be tested and read the output data. After a period of time, take out the electrode and clean it.

Measure the pH of the water sample:

First rinse the electrode with distilled water, then rinse it with the water sample, then immerse the electrode in the sample, carefully shake the test cup or stir it to accelerate the electrode balance, let it stand, and record the pH value when the reading is stable.

2.5 Maintenance

- The equipment itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself. Contact us as soon as possible!

- There is an appropriate amount of soaking solution in the protective bottle at the front end of the electrode. The electrode head is soaked in it to keep the glass bulb and the liquid junction activated. When measuring, loosen the bottle cap, pull out the electrode, and rinse it with pure water before use.

- Preparation of electrode soaking solution: Take a packet of PH4.00 buffer, dissolve it in 250 ml of pure water, and soak it in 3M potassium chloride solution. The preparation is as follows: Take 25 grams of analytical pure potassium chloride and dissolve it in 100 ml of pure water.

- The glass bulb at the front end of the electrode cannot come into contact with hard objects. Any damage and scratches will make the electrode ineffective.

- Before measurement, the bubbles in the electrode glass bulb should be shaken off, otherwise it will affect the measurement. When measuring, the electrode should be stirred in the measured solution and then placed still to accelerate the response.

- The electrode should be cleaned with deionized water before and after measurement to ensure accuracy.

- After long-term use, the pH electrode will become passivated, which is characterized by a decrease in sensitivity gradient, slow response, and inaccurate readings. At this time, the bulb at the bottom of the electrode can be soaked in 0.1M dilute hydrochloric acid for 24 hours (0.1M dilute hydrochloric acid preparation: 9 ml of hydrochloric acid is diluted to 1000 ml with distilled water), and then soaked in 3.3M potassium chloride solution for 24 hours. If the pH electrode is seriously passivated and soaking in 0.1M hydrochloric acid has no effect, the pH electrode bulb can be soaked in 4% HF (hydrofluoric acid) for 3-5 seconds, washed with pure water, and then soaked in 3.3M potassium chloride solution for 24 hours to restore its performance.

- Glass bulb contamination or liquid junction blockage can also cause electrode passivation. At this time, it should be cleaned with an appropriate solution according to the nature of the contaminant.

- The equipment should be calibrated before each use. For long-term use, it is recommended to calibrate once every 3 months. The calibration frequency should be adjusted appropriately according to different application conditions (degree of dirt in the application, deposition of chemical substances, etc.). After aging, the electrodes should be replaced in time.

2.6 RS485 Commands

RS485 signaldefault address 0x10

Standard Modbus-RTU protocol, baud rate: 9600; check bit: none; data bit: 8; stop bit: 1

2.6.1 Query address

send:

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0XFE | 0X03 | 0X00 | 0X50 | 0X00 | 0X00 | 0X51 | 0XD4 |

response:

| New address | Function code | Data length | CRC16 low | CRC16 high |

|---|---|---|---|---|

| 0X01 | 0X03 | 0X00 | 0X20 | 0XF0 |

2.6.2 Change address

For example: Change the address of the sensor with address 1 to 2, master → slave

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X06 | 0X00 | 0X50 | 0X00 | 0X02 | 0X08 | 0X1A |

If the sensor receives correctly, the data is returned along the original path.

Note: If you forget the original address of the sensor, you can use the broadcast address 0XFE instead. When using 0XFE, the host can only connect to one slave, and the return address is still the original address, which can be used as a method of address query.

2.6.3 Modify intercept

send:

| Address | Function code | Starting register address high | Starting register address low | Register Length high | Register Length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X10 | 0X06 | 0X00 | 0X10 | 0X00 | 0X64 | 0X8A | 0XA5 |

Change the intercept of the sensor at address 10 to 1 (default is 0). You need to pass the intercept 1*100 =100 into the command 0x006.

response:

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X10 | 0X06 | 0X00 | 0X10 | 0X00 | 0X64 | 0X8A | 0XA5 |

2.6.4 Query data

Query the data (PH) of the sensor (address 10), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X10 | 0X03 | 0X00 | 0X00 | 0X00 | 0X01 | 0X87 | 0X4B |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X10 | 0X03 | 0X02 | 0X02 | 0XAE | 0XC4 | 0X9B |

The query data command is 10 03 00 00 00 01 87 4B. After the query, 7 bytes will be returned.

For example, the returned data is 10 03 02 02 AE C4 9B.

02 AE is the pH value, which is converted into decimal to get 686, and then two decimal places are added to get the actual value. 02 AE means the current pH value is 6.86.

2.6.5 Calibration Method

This device uses three-point calibration, and three known pH standard solutions need to be prepared.

The calibration steps are as follows:

(1) Place the electrode in distilled water to clean it, and then place it in 9.18 standard buffer solution. After the data stabilizes, enter the following calibration command, and the 9.18 calibration is completed.

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X10 | 0X06 | 0X00 | 0X20 | 0XFF | 0XFF | 0X8A | 0XF1 |

(2) Wash the electrode in distilled water and place it in 6.86 standard buffer. After the data stabilizes, enter the following calibration command. The 6.86 calibration is completed.

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X10 | 0X06 | 0X00 | 0X21 | 0XFF | 0XFF | 0XDB | 0X31 |

(3) Wash the electrode in distilled water and place it in 4.01 standard buffer. After the data stabilizes, enter the following calibration command, and the 4.00 calibration is completed.

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X10 | 0X06 | 0X00 | 0X22 | 0XFF | 0XFF | 0X2B | 0X31 |

After the above three steps are completed, the calibration is successful. The advantage of three-point calibration compared to two-point calibration is that the electrode is calibrated separately in the acid and alkali parts, thereby achieving accurate calibration of the full range and making the measurement data more accurate.

3. DR-ORP1 Water ORP Sensor

3.1 Specification

- Power Input: DC7~30

- Measuring range: -1999~1999mV

- Resolution: 1mV

- Interface: RS485. 9600 Baud Rate

- Measurement error: ±3mV

- Stability: ≤2mv/24 hours

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- IP Rated: IP68

- Max Pressure: 0.6MPa

3.2 Wiring

3.3 Mechinical Drawing

3.4 Installation Notice

Do not power on while connect the cables. Double check the wiring before power on.

Installation Photo as reference:

Submerged installation:

The lead wire of the equipment passes through the waterproof pipe, and the 3/4 thread on the top of the equipment is connected to the 3/4 thread of the waterproof pipe with raw tape. Ensure that the top of the equipment and the equipment wire are not flooded.

Pipeline installation:

Connect the equipment to the pipeline through the 3/4 thread.

3.5 Maintenance

(1) The equipment itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself, and contact us as soon as possible.

(2) In general, ORP electrodes do not need to be calibrated and can be used directly. When there is doubt about the quality and test results of the ORP electrode, the electrode potential can be checked with an ORP standard solution to determine whether the ORP electrode meets the measurement requirements, and the electrode can be recalibrated or replaced with a new ORP electrode. The frequency of calibration or inspection of the measuring electrode depends on different application conditions (the degree of dirt in the application, the deposition of chemical substances, etc.).

(3) There is an appropriate soaking solution in the protective bottle at the front end of the electrode, and the electrode head is soaked in it to ensure the activation of the platinum sheet and the liquid junction. When measuring, loosen the bottle cap, pull out the electrode, and rinse it with pure water before use.

(4) Preparation of electrode soaking solution: Take 25 grams of analytical pure potassium chloride and dissolve it in 100 ml of pure water to prepare a 3.3M potassium chloride solution.

(5) Before measuring, the bubbles in the electrode glass bulb should be shaken off, otherwise it will affect the measurement. When measuring, the electrode should be stirred in the measured solution and then placed still to accelerate the response.

(6) The electrode should be cleaned with deionized water before and after the measurement to ensure the measurement accuracy.

(7) After long-term use, the ORP electrode will be passivated, which is manifested as a decrease in sensitivity gradient, slow response, and inaccurate readings. At this time, the platinum sheet at the bottom of the electrode can be soaked in 0.1M dilute hydrochloric acid for 24 hours (0.1M dilute hydrochloric acid preparation: 9 ml of hydrochloric acid is diluted to 1000 ml with distilled water), and then soaked in 3.3M potassium chloride solution for 24 hours to restore its performance.

(8) Electrode contamination or liquid junction blockage can also cause electrode passivation. At this time, it should be cleaned with an appropriate solution according to the nature of the contaminant. If the platinum of the electrode is severely contaminated and an oxide film is formed, toothpaste can be applied to the platinum surface and then gently scrubbed to restore the platinum's luster.

(9) The equipment should be calibrated before each use. It is recommended to calibrate once every 3 months for long-term use. The calibration frequency should be adjusted appropriately according to different application conditions (degree of dirt in the application, deposition of chemical substances, etc.). After aging, the electrodes should be replaced in time.

3.6 RS485 Commands

RS485 signaldefault address 0x13

Standard Modbus-RTU protocol, baud rate: 9600; check bit: none; data bit: 8; stop bit: 1

3.6.1 Query address

send:

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0XFE | 0X03 | 0X00 | 0X50 | 0X00 | 0X00 | 0X51 | 0XD4 |

response:

| New address | Function code | Data length | CRC16 low | CRC16 high |

|---|---|---|---|---|

| 0X01 | 0X03 | 0X00 | 0X20 | 0XF0 |

3.6.2 Change address

For example: Change the address of the sensor with address 1 to 2, master → slave

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X06 | 0X00 | 0X50 | 0X00 | 0X02 | 0X08 | 0X1A |

If the sensor receives correctly, the data is returned along the original path.

Note: If you forget the original address of the sensor, you can use the broadcast address 0XFE instead. When using 0XFE, the host can only connect to one slave, and the return address is still the original address, which can be used as a method of address query.

3.6.3 Modify intercept

send:

| Address | Function code | Starting register address high | Starting register address low | Register Length high | Register Length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X13 | 0X06 | 0X00 | 0X10 | 0X00 | 0X64 | 0X8A | 0X96 |

Change the intercept of the sensor with address 1 to 10 (default 0), which is 0X000A in the command.

response:

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X13 | 0X06 | 0X00 | 0X10 | 0X00 | 0X64 | 0X8A | 0X96 |

3.6.4 Query data

Query the data (ORP) of the sensor (address 13), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X13 | 0X03 | 0X00 | 0X00 | 0X00 | 0X01 | 0X87 | 0X78 |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X13 | 0X03 | 0X02 | 0X02 | 0XAE | 0X80 | 0X9B |

The query data command is 13 03 00 00 00 01 87 78

For example, the returned data is 13 03 02 02 AE 80 9B.

02 AE is the ORP value, converted to decimal, the actual value is 686, 02 AE means the current ORP value is 686mV

3.6.5 Calibration Method

This device uses two-point calibration, and two known ORP standard solutions need to be prepared. The calibration steps are as follows:

(1) Place the electrode in distilled water to clean it, and then place it in 86mV standard buffer solution. After the data stabilizes,

enter the following calibration command, and the 86mV point calibration is completed;

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X13 | 0X06 | 0X00 | 0X24 | 0XFF | 0XFF | 0XCB | 0X03 |

Wash the electrode in distilled water and place it in 256mV standard buffer. After the data is stable, enter the following calibration command to complete the 256mV point calibration.

| Address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X13 | 0X06 | 0X00 | 0X25 | 0XFF | 0XFF | 0X9A | 0XC3 |

4. DR-DO1 Dissolved Oxygen Sensor

4.1 Specification

- Measuring range: 0-20mg/L, 0–50℃

- Accuracy: 3%, ±0.5℃

- Resolution: 0.01 mg/L, 0.01℃

- Maximum operating pressure: 6 bar

- Output signal: A: 4-20mA (current loop)B: RS485 (standard Modbus-RTU protocol, device default address: 01)

- Power supply voltage: 5-24V DC

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Power consumption: ≤0.5W

4.2 wiring

4.3 Impedance requirements for current signals

| Supply Voltage | 9V | 12V | 20V | 24V |

| Max Impedance | <250Ω | <400Ω | <500Ω | <900Ω |

4.4 Mechinical Drawing

4.5 Instructions for use and maintenance

- It can be directly put into water without adding a protective tube, ensuring the long-term stability, reliability and accuracy of the sensor.

- If the water conditions are complex and you want accurate data, you need to wipe the sensor probe frequently.

4.6 RS485 Commands

RS485 signaldefault address 0x14

Standard Modbus-RTU protocol, baud rate: 9600; check bit: none; data bit: 8; stop bit: 1

4.6.1 Query address

send:

| Original address | Function code | Register address high | Register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0XFF | 0X03 | 0X00 | 0X0A | 0X00 | 0X02 | 0XF1 | 0XD7 |

If you forget the original address of the sensor, you can use the broadcast address 0XFF instead. When using 0XFE, the host can only connect to one slave, which can be used as a method of address query.

response:

Register 0 data high and register 0 data low indicate the actual address of the sensor: 1

Register 1 data high and register 1 data low indicate the sensor version

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | Register 1 Data high | Register 1 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|---|

| 0XFF | 0X03 | 0X04 | 0X00 | 0X01 | 0X00 | 0X00 | 0XB4 | 0X3C |

4.6.2 Change address

For example: Change the address of the sensor with address 1 to 2(address range: 1-119), master → slave

| Original address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | Data length | Start address high | Start address low | Sensor version | Sensor version | CRC16 high | CRC16 low |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X00 | 0X0A | 0X00 | 0X02 | 0X04 | 0X00 | 0X02 | 0X00 | 0X00 | 0XD2 | 0X10 |

response:

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X00 | 0X0A | 0X00 | 0X02 | 0X61 | 0XCA |

4.6.3 Query data

Query the data (dissolved oxygen) of the sensor (address 14), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X14 | 0X03 | 0X00 | 0X14 | 0X00 | 0X01 | 0XC6 | 0XCB |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X14 | 0X03 | 0X02 | 0X03 | 0X78 | 0XB5 | 0X55 |

After the query, 7 bytes will be returned. For example, the returned data is 14 03 02 03 78 B5 55. 03 78 is the value of dissolved oxygen.

Converted to decimal, it is 888. Add two decimal places to get the actual value. 03 78 means the current dissolved oxygen is 8.88mg/L

Query the data (temperature) of the sensor (address 14), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X14 | 0X03 | 0X00 | 0X11 | 0X00 | 0X01 | 0XD6 | 0XCA |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X14 | 0X03 | 0X02 | 0X09 | 0XA4 | 0XB2 | 0X6C |

After the query, 7 bytes will be returned. For example, the returned data is 14 03 02 09 A4 B2 6C. 03 78 is the value of dissolved oxygen temperature.

Converted to decimal, it is 2468. Add two decimal places to get the actual value. 09 A4 means the current dissolved oxygen temperature is 24.68°C

5. DR-TS1 Water Turbidity Sensor

5.1 Specification

- Measuring range: 0.1~1000.0NTU

- Accuracy: ±5%

- Resolution: 0.1NTU

- Stability: ≤3mV/24 hours

- Output signal: RS485 (standard Modbus-RTU protocol, device default address: 01)

- Power supply voltage: 5~24V DC (when output signal is RS485), 12~24V DC (when output signal is 4~20mA)

- Working environment:

- Ambient Temperature: 0–60°C

- Relative Humidity: <85% RH(Specifically refers to the cable male and female)

- Power consumption: ≤ 0.5W

5.2 wiring

5.3 Impedance requirements for current signals

| Supply Voltage | 9V | 12V | 20V | 24V |

| Max Impedance | <250Ω | <400Ω | <500Ω | <900Ω |

5.4 Mechinical Drawing

5.5 Instructions for use and maintenance

- It can be directly put into water without adding a protective tube, ensuring the long-term stability, reliability and accuracy of the sensor.

- If the water conditions are complex and you want accurate data, you need to wipe the sensor probe frequently.

5.6 RS485 Commands

RS485 signaldefault address 0x15

Standard Modbus-RTU protocol, baud rate: 9600; check bit: none; data bit: 8; stop bit: 1

5.6.1 Query address

send:

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0XFE | 0X03 | 0X00 | 0X50 | 0X00 | 0X00 | 0X51 | 0XD4 |

If you forget the original address of the sensor, you can use the broadcast address 0XFE instead. When using 0XFE, the host can only connect to one slave, which can be used as a method of address query.

response:

| New address | Function code | Data length | CRC16 low | CRC16 high |

|---|---|---|---|---|

| 0X01 | 0X03 | 0X00 | 0X20 | 0XF0 |

5.6.2 Change address

For example: Change the address of the sensor with address 1 to 2, master → slave

| Original address | Function code | Address high | Address low | Quantity high | Quantity low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X06 | 0X00 | 0X50 | 0X00 | 0X02 | 0X08 | 0X1A |

If the sensor receives correctly, the data is returned along the original path.

Note: If you forget the original address of the sensor, you can use the broadcast address 0XFE instead. When using 0XFE, the host can only connect to one slave, and the return address is still the original address, which can be used as a method of address query.

5.6.3 Query data

Query the data (turbidity) of the sensor (address 15), host → slave

| Address | Function code | Starting register address high | Starting register address low | Register length high | Register length low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X15 | 0X03 | 0X00 | 0X00 | 0X00 | 0X01 | 0X87 | 0X1E |

If the sensor receives correctly, the following data will be returned, slave → host

| Address | Function code | Data length | Register 0 Data high | Register 0 Data low | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|

| 0X15 | 0X03 | 0X02 | 0X02 | 0X9A | 0X09 | 0X4C |

The query data command is 15 03 00 00 00 01 87 1E

For example, the returned data is 15 03 02 02 9A 09 4C

02 9A is the turbidity value, converted to decimal, it is 666, and then divided by 10, the actual value is 66.6, 02 9A means the current turbidity value is 66.6 NTU

6. DR-CL Water CL Probe

6.1 Specification:

- Power Input: DC7~30

- Power Consumption : 0.19W

- Interface: RS485. 9600 Baud Rate

- CL Range & Resolution:

- CL2ML:0-2mg/L

- CL10ML:0-10mg/L

- Resolution:0.01mg/L

- CL Accuracy: ±5% FS

- Temperature Accuracy: ±0.5 °C

- Working environment:

- Ambient Temperature: 0–50°C

- pH:4-9

- Flow rate: 30L/h~60L/h (flow tank installation)

- IP Rated: IP68

- Max Pressure: 0.6MPa

6.2 Wiring

6.3 Mechinical Drawing

6.4 Installation

Flow-through installation: Use the matching flow slot for installation. The device and the flow slot are installed tightly.

The measuring end is completely immersed in the measured liquid to ensure a steady flow rate without bubbles.

It is recommended that the flow rate be controlled at 30-60Lh to ensure the accuracy of the test.

6.5 Maintenance

- The device itself generally does not require daily maintenance. When an obvious fault occurs, please do not open it and repair it yourself, and contact us as soon as possible!

- After using the electrode, please clean the electrode head with clean water and cover it with a protective cover.

- When measuring the device, the measured liquid should flow and the flow rate should be uniform, and there should be no bubbles attached to the measuring end of the device.

- If the electrode diaphragm is attached with dirt and mineral components, the sensitivity will be reduced, and it may not be possible to perform sufficient measurement. Please ensure that the platinum ring is clean.

- The platinum induction ring of a good residual chlorine electrode should always be kept clean and bright. If the platinum ring of the electrode becomes rough or covered with pollutants after measurement, please clean it according to the following method: (For reference) Inorganic pollution: immerse the electrode in 0.1mol/L dilute hydrochloric acid for 15 minutes, gently wipe the platinum ring of the residual chlorine electrode with a cotton swab, and then wash it with tap water.

- Organic or oil pollution: immerse the electrode in tap water with a small amount of detergent, such as dishwashing liquid, and thoroughly clean the sensing surface of the electrode sensor. Gently wipe the platinum ring of the electrode with a cotton swab, then rinse with tap water, and the cleaning is complete. If the platinum ring of the electrode has formed an oxide film, please use toothpaste or 1000-grit fine sandpaper to properly polish the sensing surface, and then clean it with tap water. The platinum ring is connected to the glass, so please handle it carefully when polishing.

The electrode has a service life of about one year, and a new electrode should be replaced in time after aging. - Before the cable plug and the device plug are locked, do not put the plug part into water.

6.6 RS485 Commands

RS485 signal

Standard Modbus-RTU protocol, baud rate: 9600; check bit: none; data bit: 8; stop bit: 1

6.7 Query data

Example 1: Read the current residual chlorine concentration of the device with address 01

| Address | Function code | Register Address | Register length | CRC16 low | CRC16 high |

|---|---|---|---|---|---|

| 0X01 | 0X03 | 0X00 0X00 | 0X00 0X01 | 0X84 | 0X0A |

response:

| Address | Function code | Valid Bytes | Register contents | CRC16 low | CRC16 high |

|---|---|---|---|---|---|

| 0X01 | 0X03 | 0X02 | 0X03 0X16 | 0X39 | 0X7A |

Calculation of residual chlorine concentration: 316H (hexadecimal) = 790 => residual chlorine = 7.90

Example 2: Set the deviation value for the current residual chlorine value of the device with address 01 to correct the value and send the frame: (If the current residual gas value output by the device is 7.90, the value needs to be corrected to 8.00, the difference is 8.00-7.90-0.100.1*100=10=>41200000 (floating point number), write 41200000 to the contents of the two registers)

| Original address | Function code | Register address | Register number | Byte number | Register content | CRC16 low | CRC16 high |

|---|---|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X01 0X12 | 0X00 0X02 | 0X04 | 0X4120 0X0000 | 0X08 | 0X1A |

response:

| Address | Function code | Register address | Register number | CRC16 low | CRC16 high |

|---|---|---|---|---|---|

| 0X01 | 0X10 | 0X01 0X12 | 0X00 0X02 | 0XE5 | 0X0D |